Spinning creel for a twisting machine

A technology for spinning bobbins and creels, which is applied in the fields of spinning bobbins, twisting machines, and ring twisting machines. It can solve the problem of interruption, yarn or filament breakage, uncontrollable and safe use, etc. problem, to achieve the effect of cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

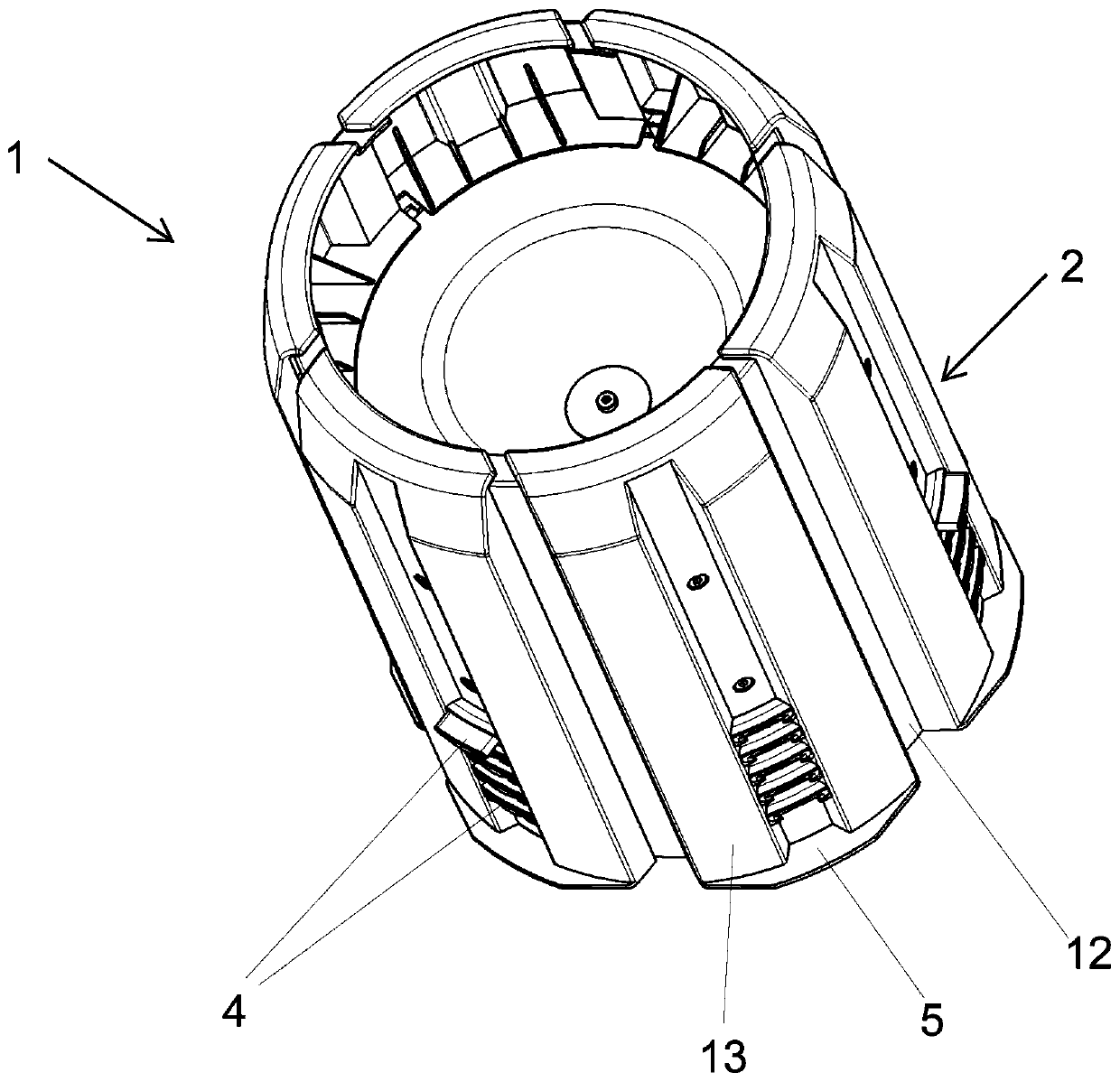

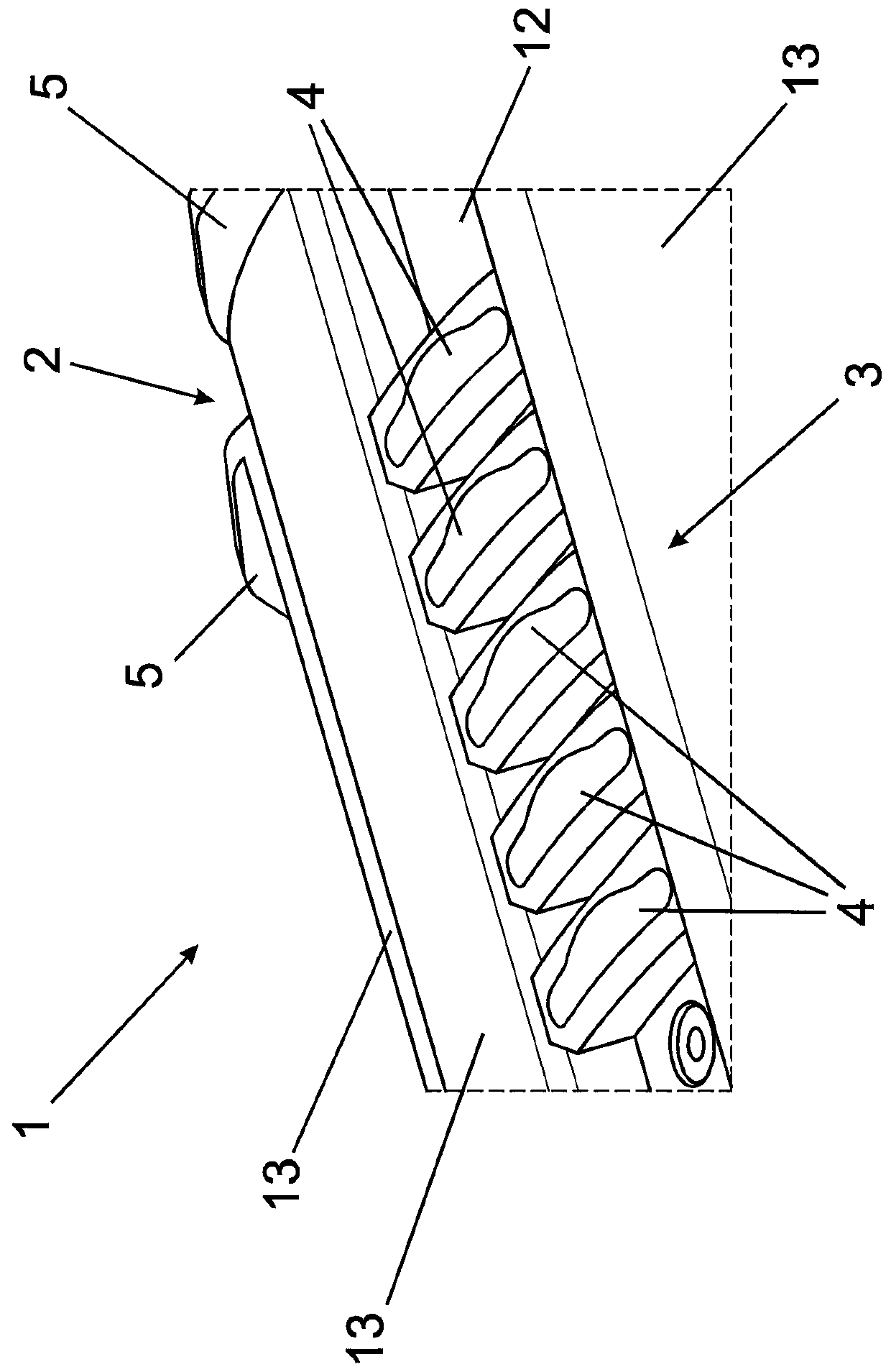

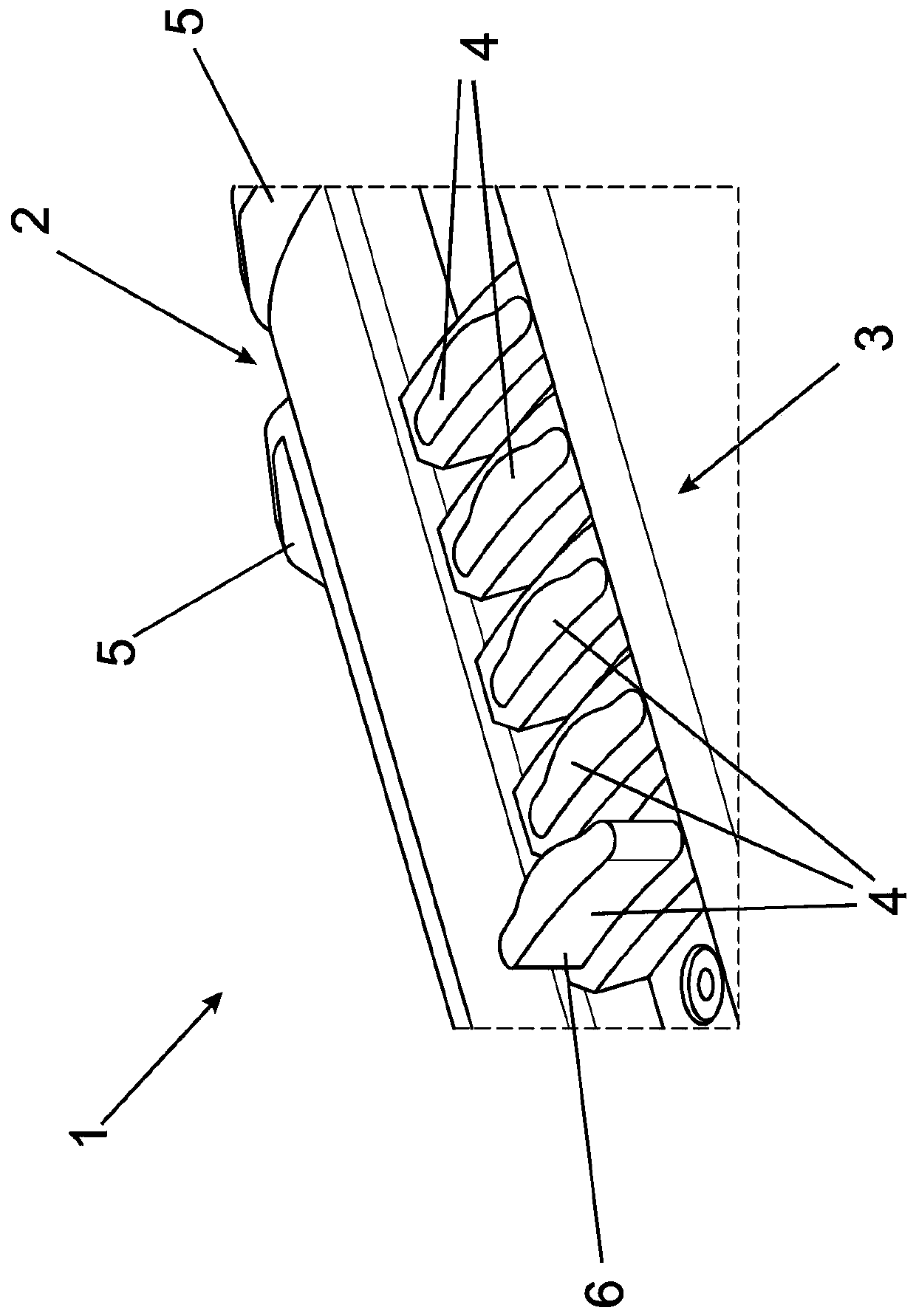

[0052] exist figure 1 as shown in Figure 1a In a spinning creel 1 for a high-efficiency ring twisting machine shown in part, the containing body 2 is arranged rotatably around the creel axis, so that the spinning The bobbin feeds the spinning bobbin yarn to the high-efficiency ring twisting machine. The spinning creel 1 here has an electric motor drive unit, which can rotate the receiving body 2 via the creel shaft.

[0053] The receiving body 2 has a main body 12 containing the creel shaft and a plurality of clamping bodies 13 arranged evenly distributed on the outer circumference of the receiving body 2, wherein the clamping bodies 13 are movable away from the main body 12 in the radial direction with respect to the creel shaft, so as to be able to The spinning bobbin pushed onto the receiving body 2 in the receiving area 3 is secured in a non-positive manner. Each clamping body 13 has at one end a fixed end stop 5 which delimits the end of the receiving area 3 in the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com