Combined mine development system based on shaft and packaging tape inclined shaft

A technology of tape and inclined shaft is applied in the field of joint mine development system, which can solve the problems of difficult support, long construction period, poor rock mass stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

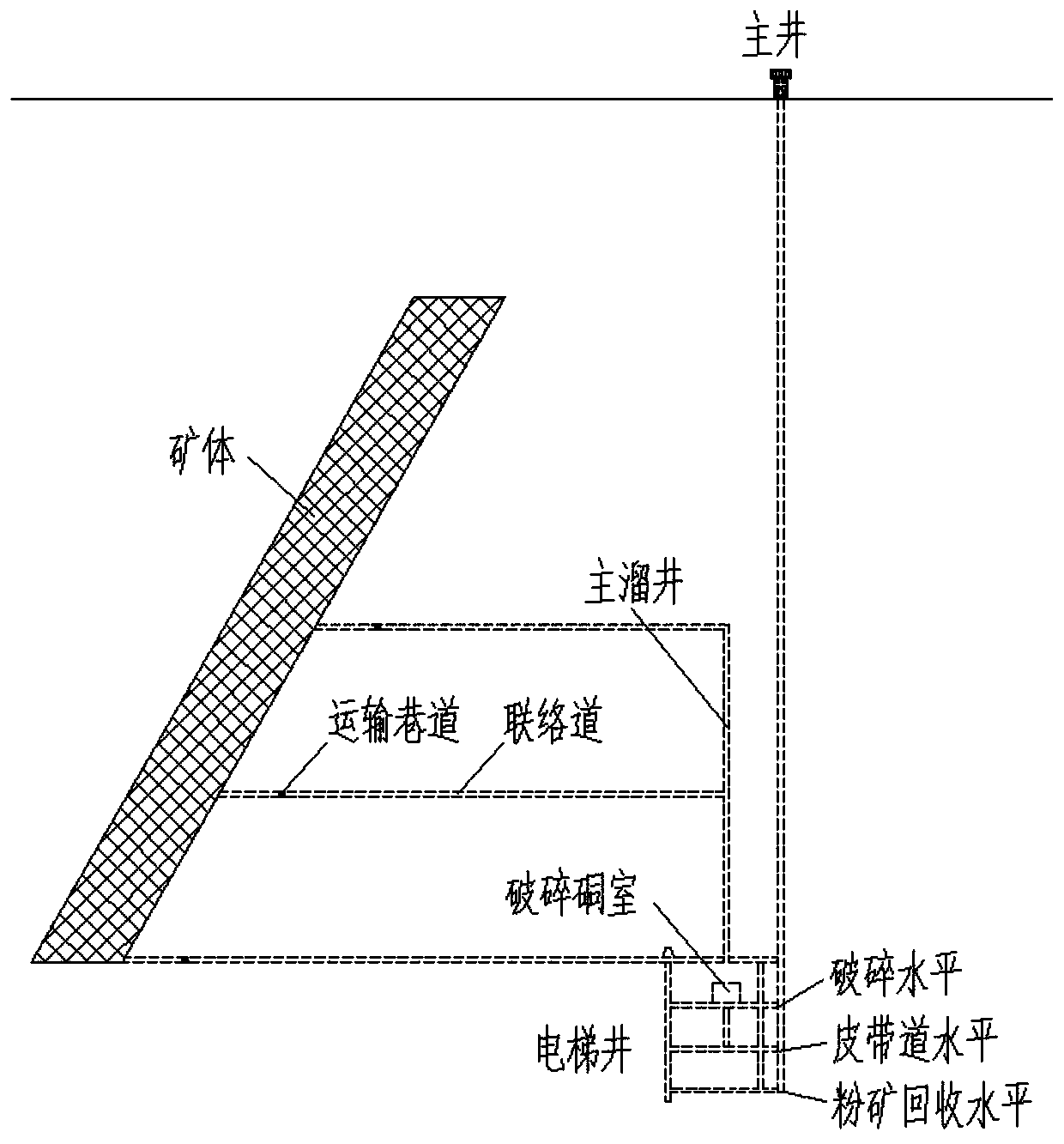

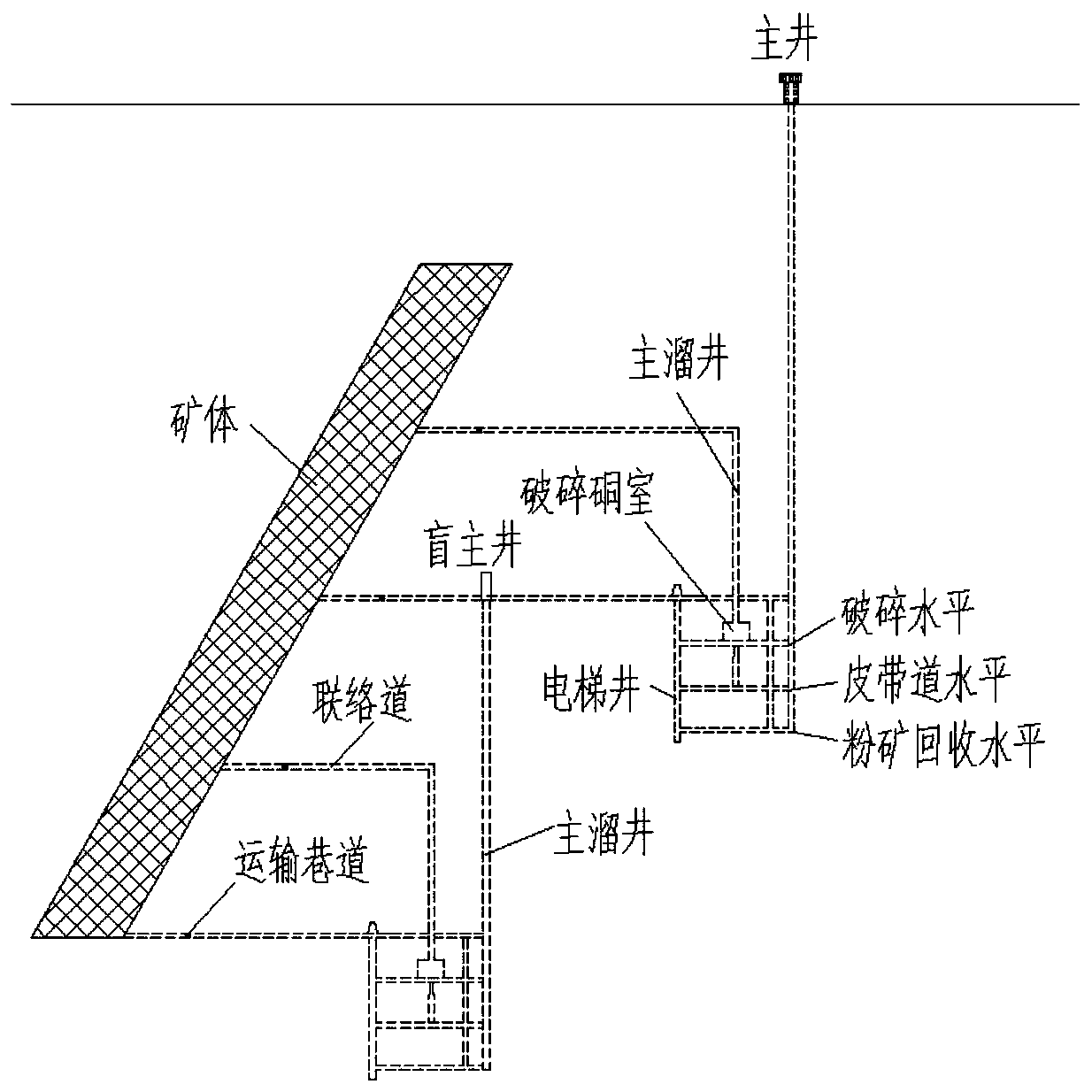

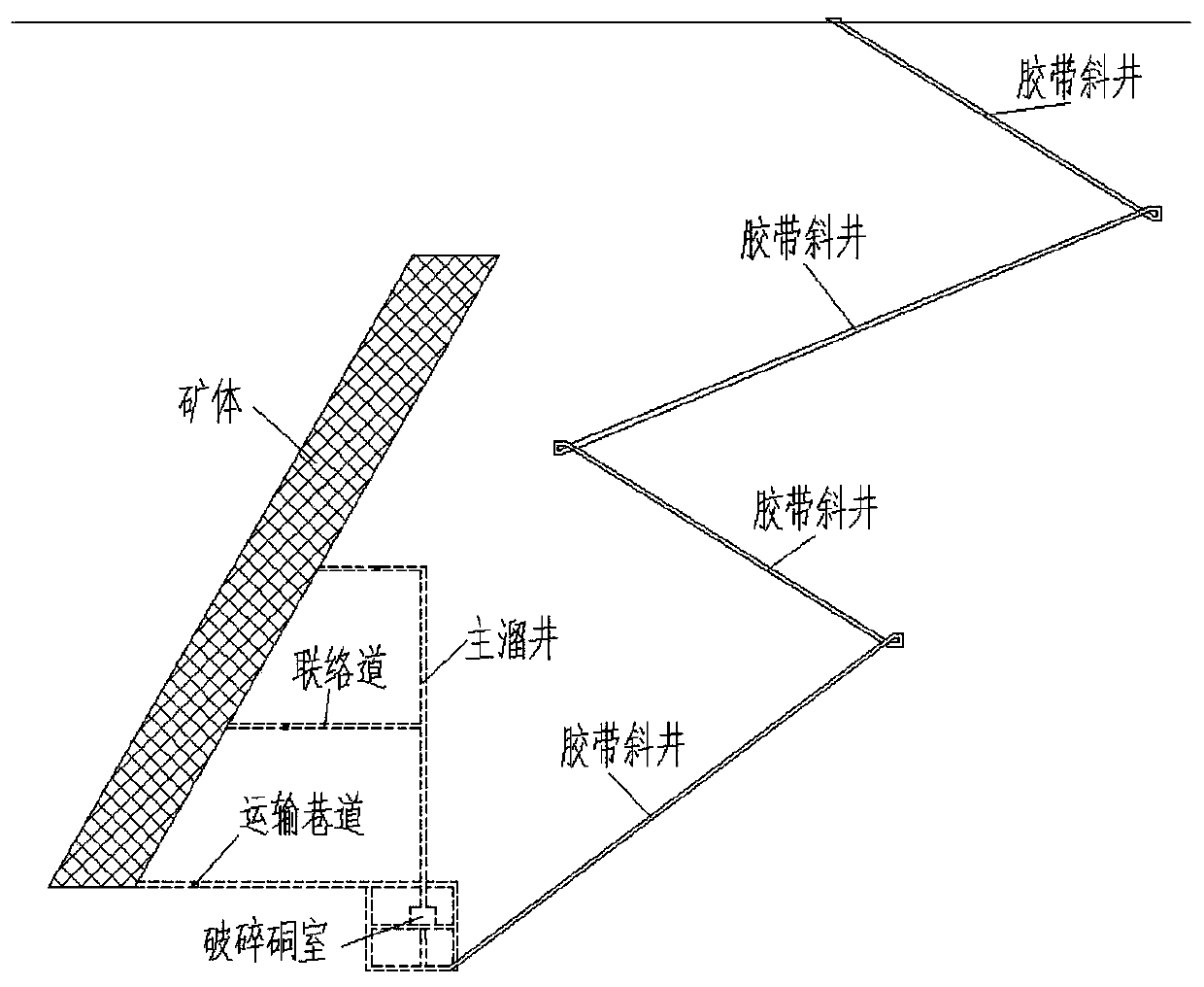

[0025] Such as Figure 4 As shown, the present invention is a combined mine development system based on vertical shafts and belt inclined shafts. The development system mainly includes the upper part of the main shaft 1 and the lower belt inclined shaft 2. The main shaft 1 adopts shaft skips to lift ore, and the belt inclined shaft 2 Use the belt conveyor to lift the ore. In the part close to the surface, due to the poor stability of the rock mass, the main shaft 1 is in the form of a vertical shaft, which reduces the construction period. Smaller, the transportation distance is shortened.

[0026] In the background technology, there is a single shaft development system in the prior art. When the lifting height of a single section of the shaft exceeds 1000m, the replacement frequency of the steel wire rope will be accelerated, which will affect mine production and economic benefits. In view of this, the lifting height of the main shaft 1 of the present invention is not high. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com