Design method of low-cost composite excitation filling cementing material

A cementing material and composite excitation technology, which is applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as difficulty in obtaining the optimized formula of mine tailings composite excitation agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] The design method of this low-cost compound excitation filling cementitious material adopts high temperature curing to quickly obtain the optimized formula of the base activator and the base activator; Strength test; on this basis, the compound activator optimization model is established to optimize the ratio; finally, the strength verification test of the cemented filling body is carried out and the economic analysis of the filling cementitious material is carried out. Its embodiment specifically comprises the following steps:

[0038] 1. Formulation design of salt-based activator

[0039] (1) According to the available salt-based activator materials, determine that the salt activator is industrial by-product gypsum, preferably desulfurized gypsum; the moisture content of sulfate activator powder is 3 Content>38wt%, powder fineness<15%;

[0040] (2) The ratio of the base activator is: 13-17wt% of the base activator, 2-6 wt% of the base activator, 0-1.0 wt% of industri...

Embodiment 1

[0065] Aiming at the whole tailings of an iron mine in Hebei, the design method of low-cost filling cementitious material for the subsequent filling method mining of an iron mine in Hebei prepared by composite excitation includes the following steps:

[0066] 1. Formulation design of salt-based activator

[0067] Aiming at filling the aggregate with tailings in an iron mine in Hebei Province, desulfurization gypsum was selected as the main activator, cement clinker was used as the auxiliary activator, and industrial Glauber's salt was added as an early strength agent to stimulate the potential activity of slag micropowder.

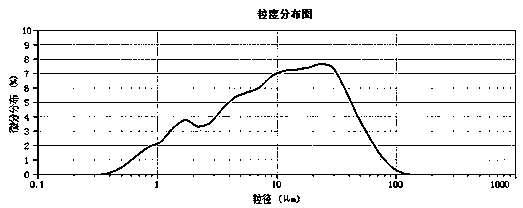

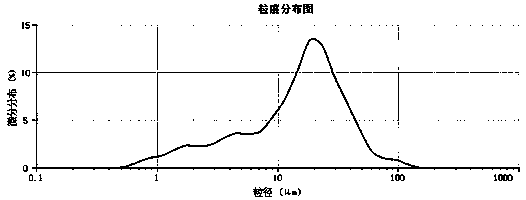

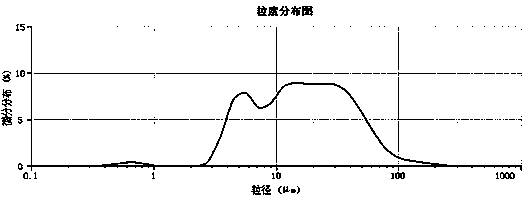

[0068] The fineness of the present embodiment slag micropowder is 4.27%, and its particle size distribution curve is as follows figure 1 Shown; the moisture content of desulfurized gypsum powder is 9.5wt%, SO 3 The content is 39.5wt%, the powder fineness is 9.2%, and its particle size distribution curve is as follows figure 2 Shown; cement clinker powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com