Mobile phone control chip packaging method

A technology for controlling chips and packaging methods, applied in the direction of electrical components, electrical components, etc., can solve the problems of circuit board packaging with various specifications, no glue coating method, sophisticated equipment, etc., to avoid errors, avoid waste of silica gel, Equipment composed of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

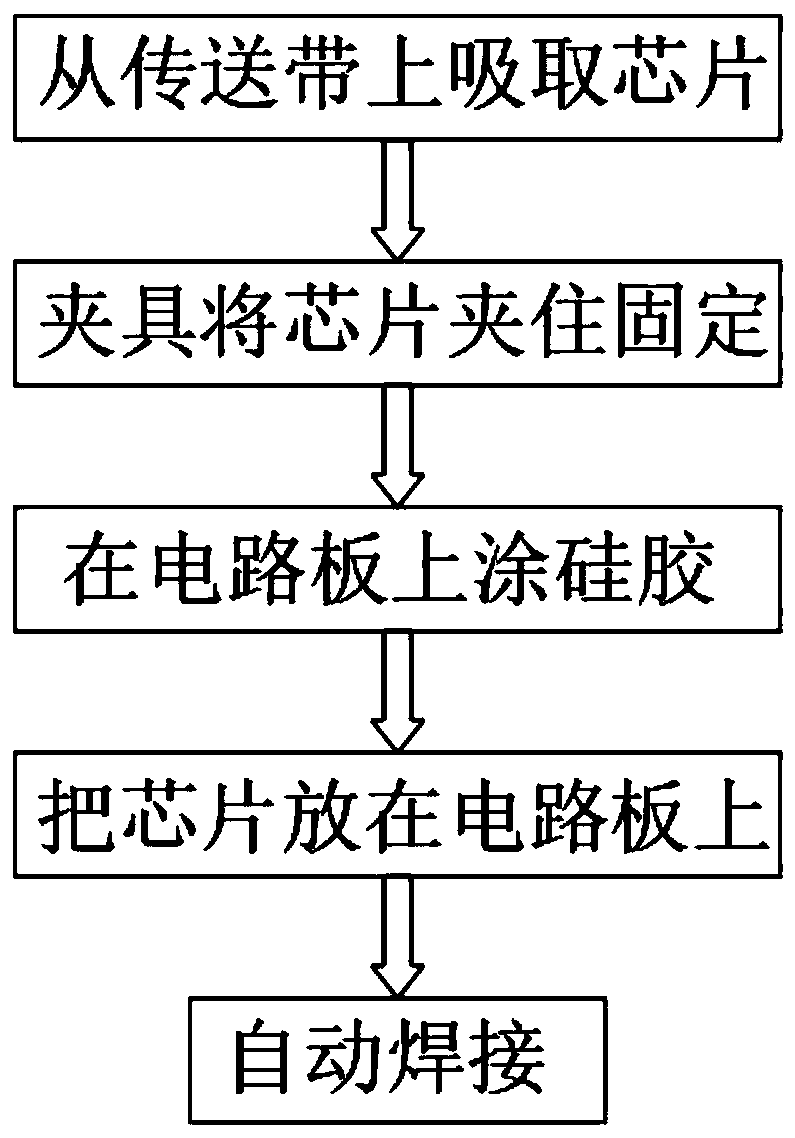

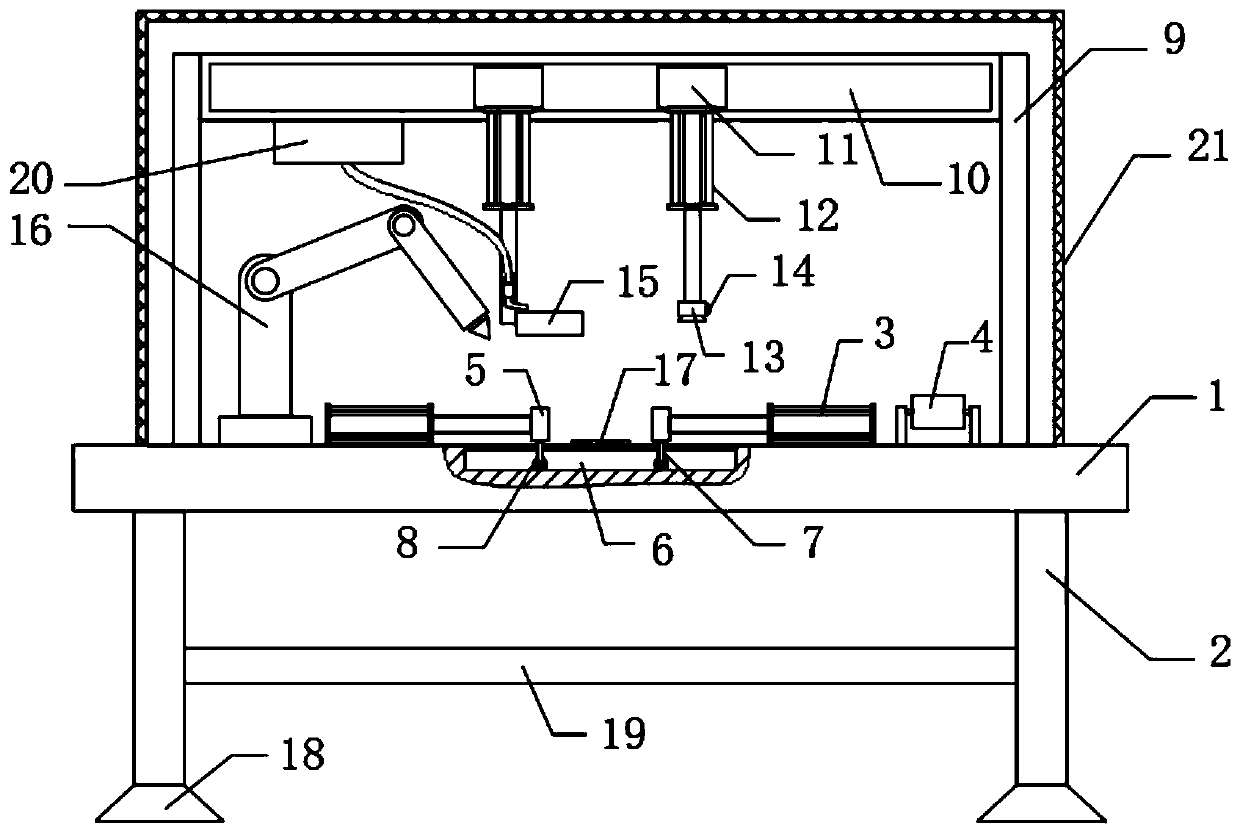

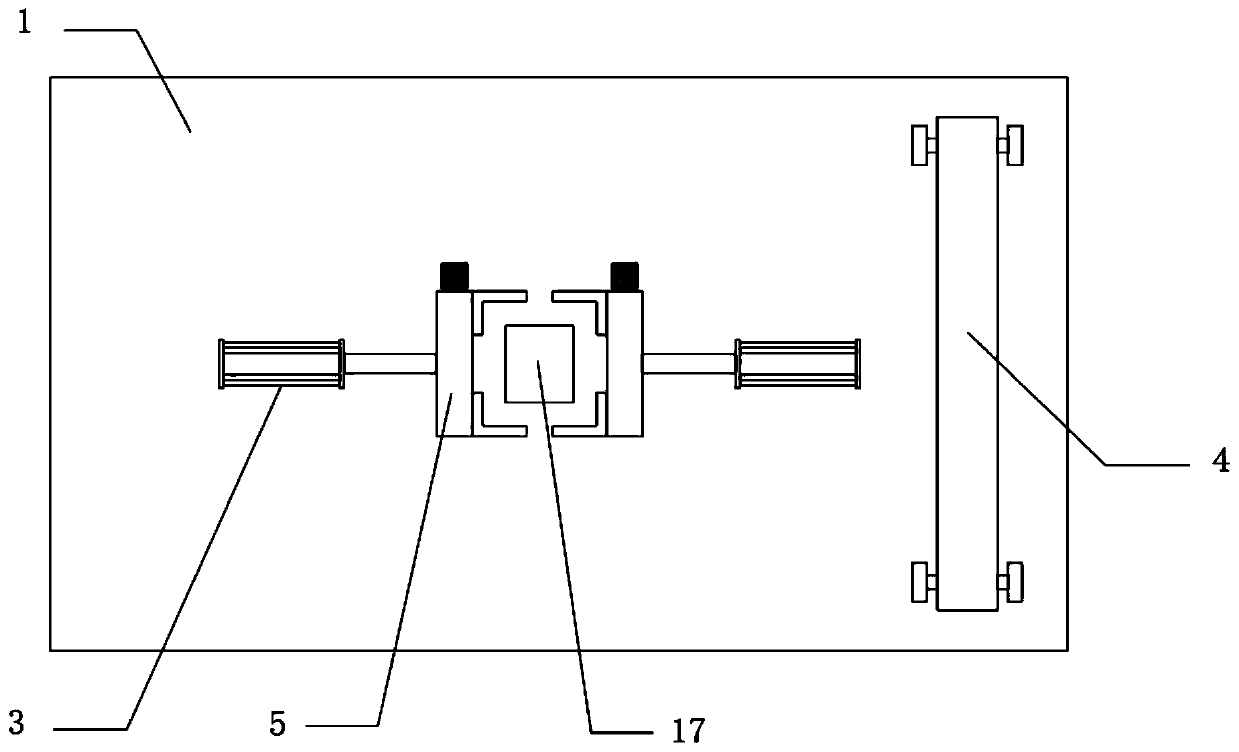

[0043] see Figure 1-5 , a mobile phone control chip packaging method, comprising a circuit board, a conveyor belt 4, a clamp 5, a negative pressure suction cup 13, a gluing device 15 and an automatic welding arm 16, comprising the following steps:

[0044] S1, put the chip on the conveyor belt 4, and the conveyor belt 4 transfers the chip to the packaging station;

[0045] S2, placing the circuit board between the two clamps 5, and clamping it by the two clamps 5;

[0046] S3, the glue coating device 15 evenly coats the silica gel on the circuit board;

[0047] S4, the negative pressure suction cup 13 accurately places the chip on the silicon-coated circuit board;

[0048] S5, the automatic welding arm 16 welds the chip on the circuit board.

[0049] Please refer to Tu 2, including the workbench 1. The upper surface of the middle part of the workbench 1 is bonded with a backing plate 17, and the backing plate 17 is made of rubber. When the negative pressure suction cup 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com