A cracked seepage irrigation pipe and its processing method

A technology of infiltration irrigation pipes and cracks, which is applied in botanical equipment and methods, watering devices, gardening, etc., can solve the problems of easy clogging of water outlet holes, water loss, and easy to be affected by water quality, etc. The effect of promoting crop growth and facilitating long-distance water delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, the present invention is described in more detail to facilitate understanding of the present invention.

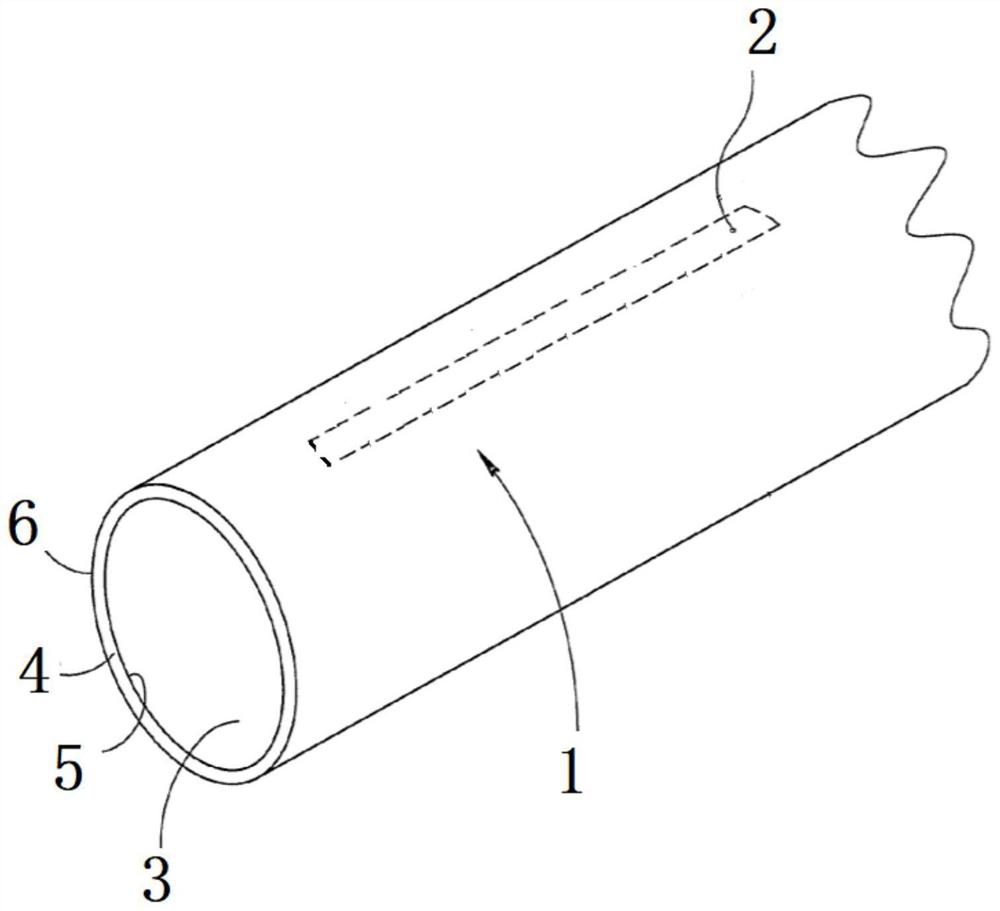

[0063] Such as Figure 1 to Figure 5 As shown, the cracked infiltration irrigation pipe of the present invention is a tubular structure, including a pipe body 1, and several uniformly distributed and uniformly oriented cracks 2 are formed on the pipe body 1 according to the fiber texture. The core layer 4 surrounds the hollow lumen 3, and the inner surface 5 and the outer surface 6 of the core layer 4 are both smooth surfaces. When water flows into the hollow lumen 3, under the action of the water flow pressure, the water pressure causes the cracks 2 to form gaps. The water inside the hollow lumen 3 flows out of the hollow lumen through the gap formed by the crack 2 along the radial direction of the pipe body, so as to realize water outlet seepage irrigation.

[0064] Preferably, the crack 2 is a flat slit.

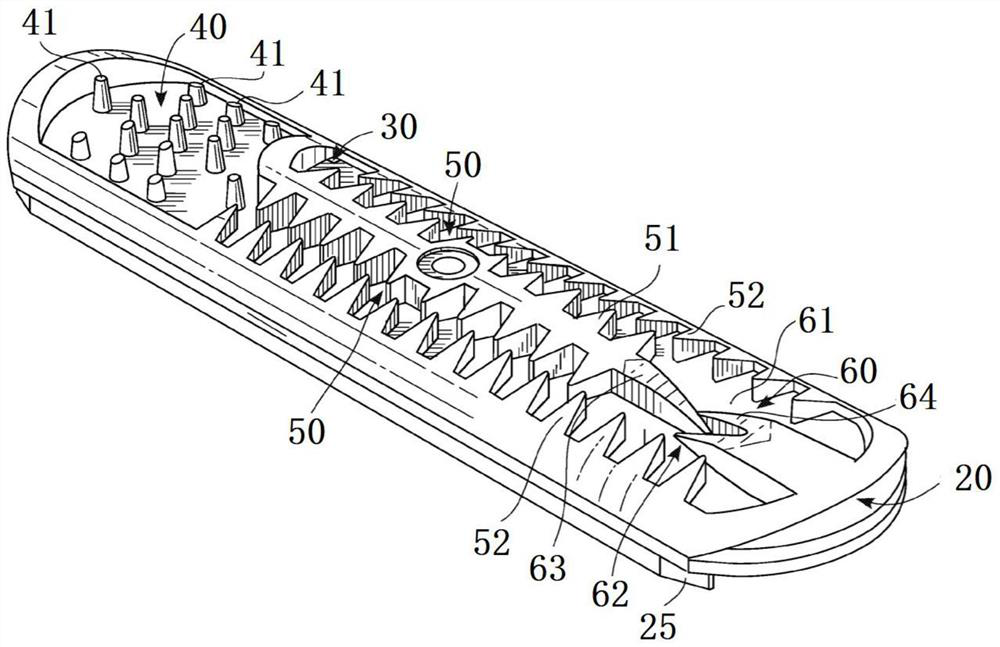

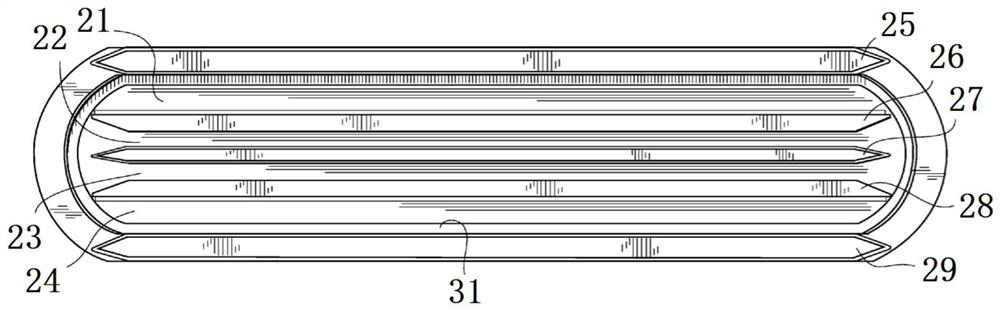

[0065] Such as Figure 2 to Figure 4 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com