Movable efficient environment-friendly grain impurity cleaning device

A cleaning device, mobile technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of inconvenient movement and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

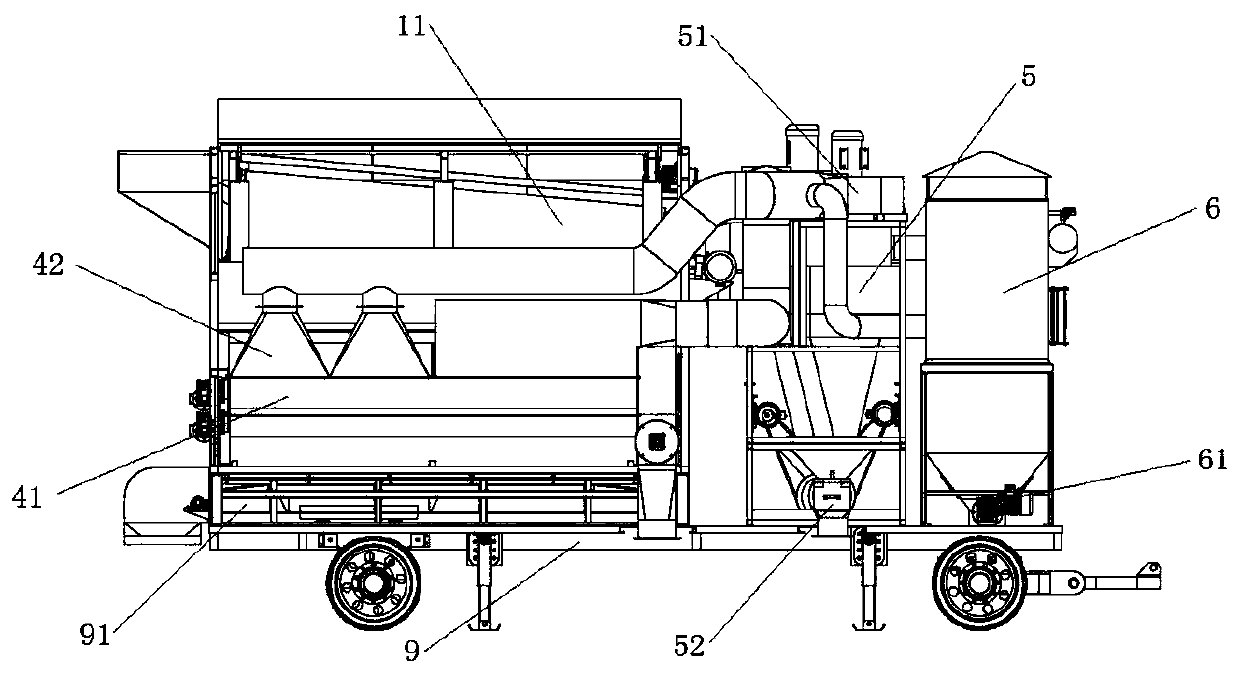

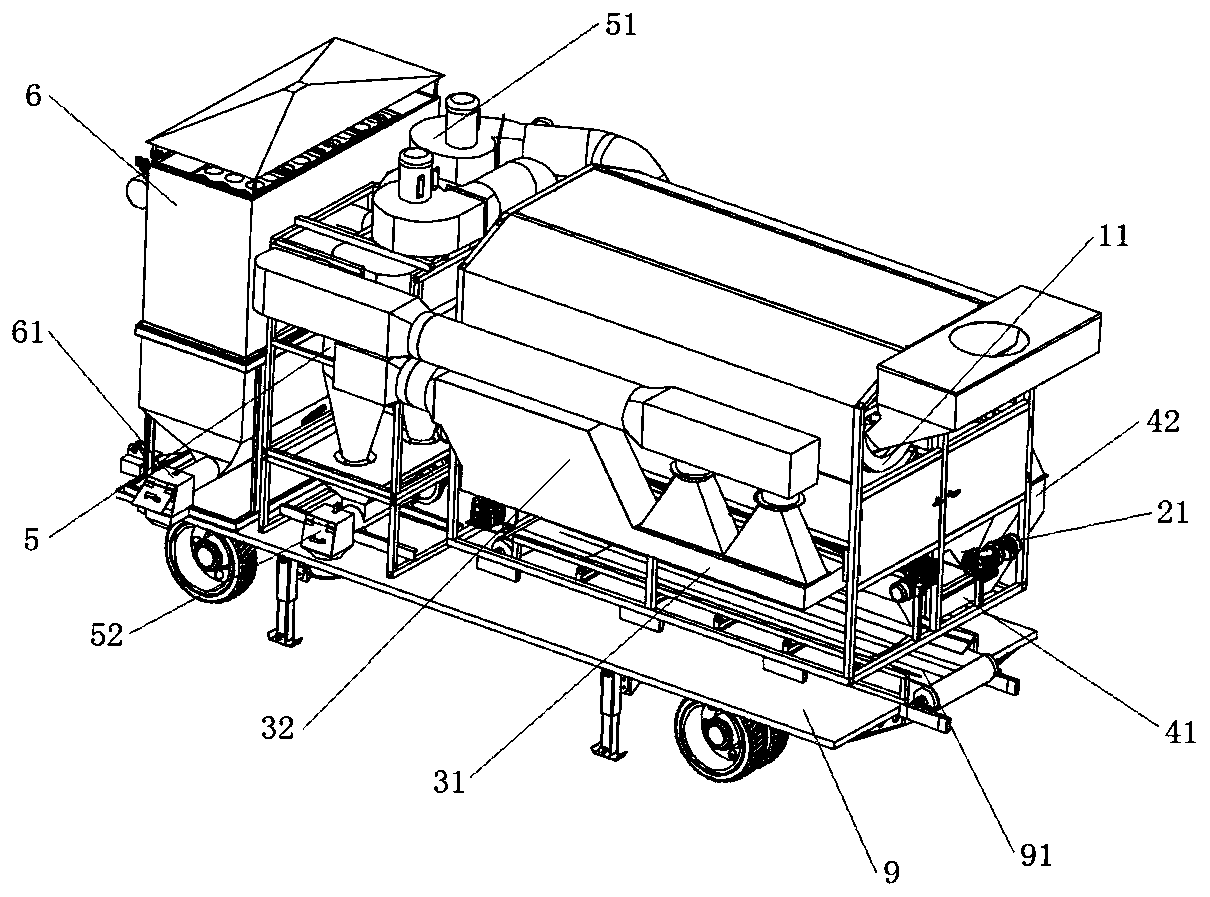

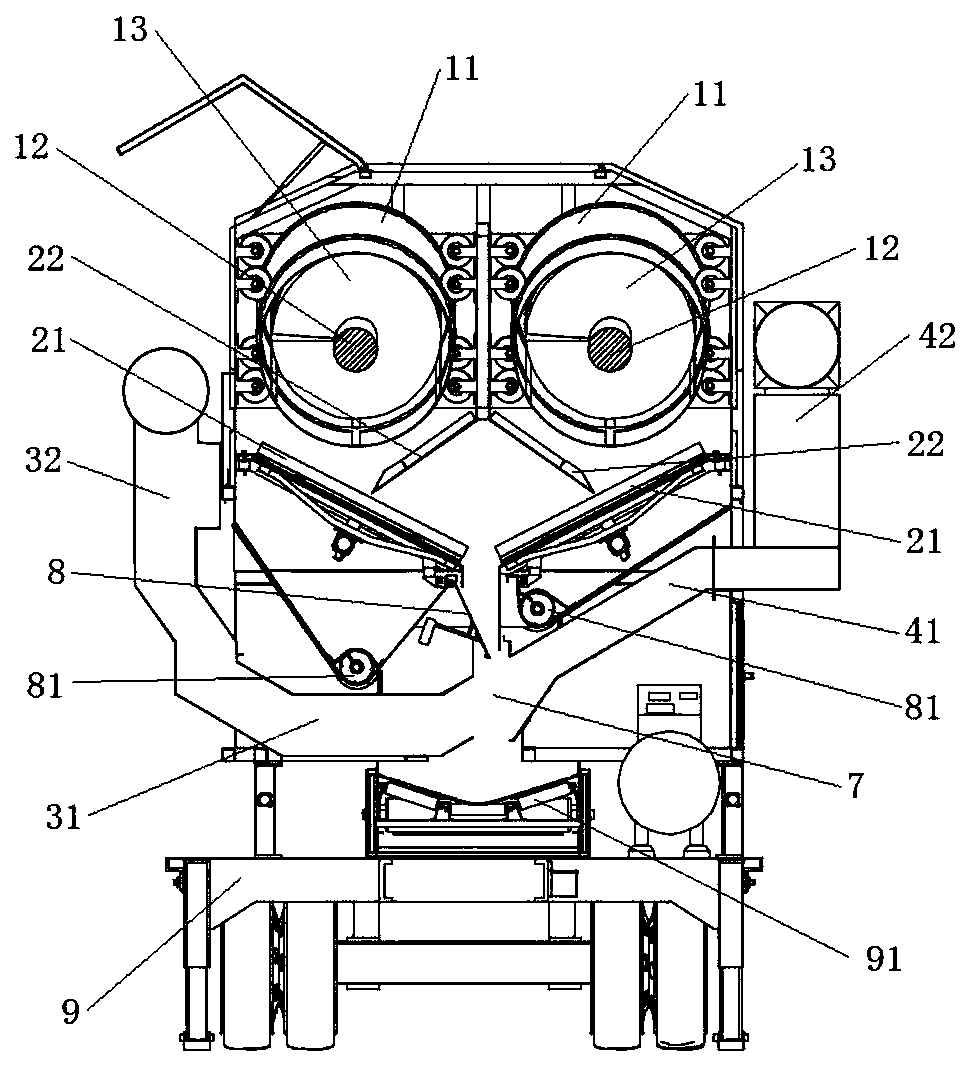

[0024] Embodiments of the present invention provide a mobile high-efficiency and environmentally friendly food impurity cleaning device, such as figure 1 , 2 , 3, 4 and 5, comprising a cylindrical screen, a vibrating screen and a circulating winnowing system arranged sequentially from top to bottom; the cylindrical screen includes a screen drum 11, and a rotating shaft 12 is arranged in the screen drum 11, so An auger blade 13 is set on the rotating shaft 12; the screen cylinder 11 is driven and connected with the first rotating motor 14; the rotating shaft 12 is driven and connected with the second rotating motor 15; the circulating winnowing system includes a suction device and a blowing device , filter device 5 and dust filter device 6, winnowing channel 7 is set between d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com