Maglev train levitation system debugging method based on digital twinning technology

A technology for maglev trains and debugging methods, applied in the field of rail transit, can solve problems such as repeated observations that cannot be visualized, large manpower, time and economic costs, and poor debugging results, so as to reduce economic costs and labor time costs, and improve work environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

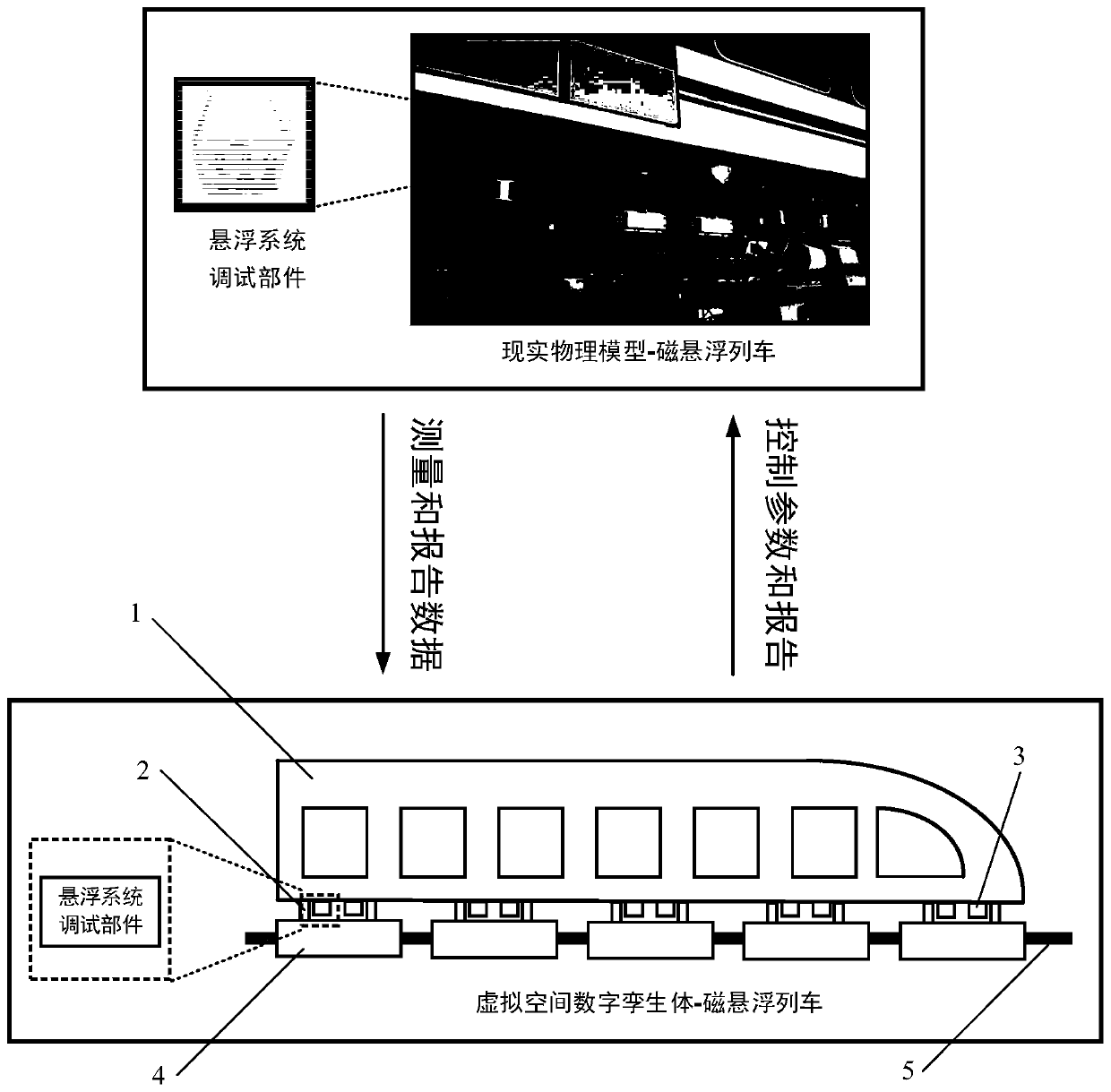

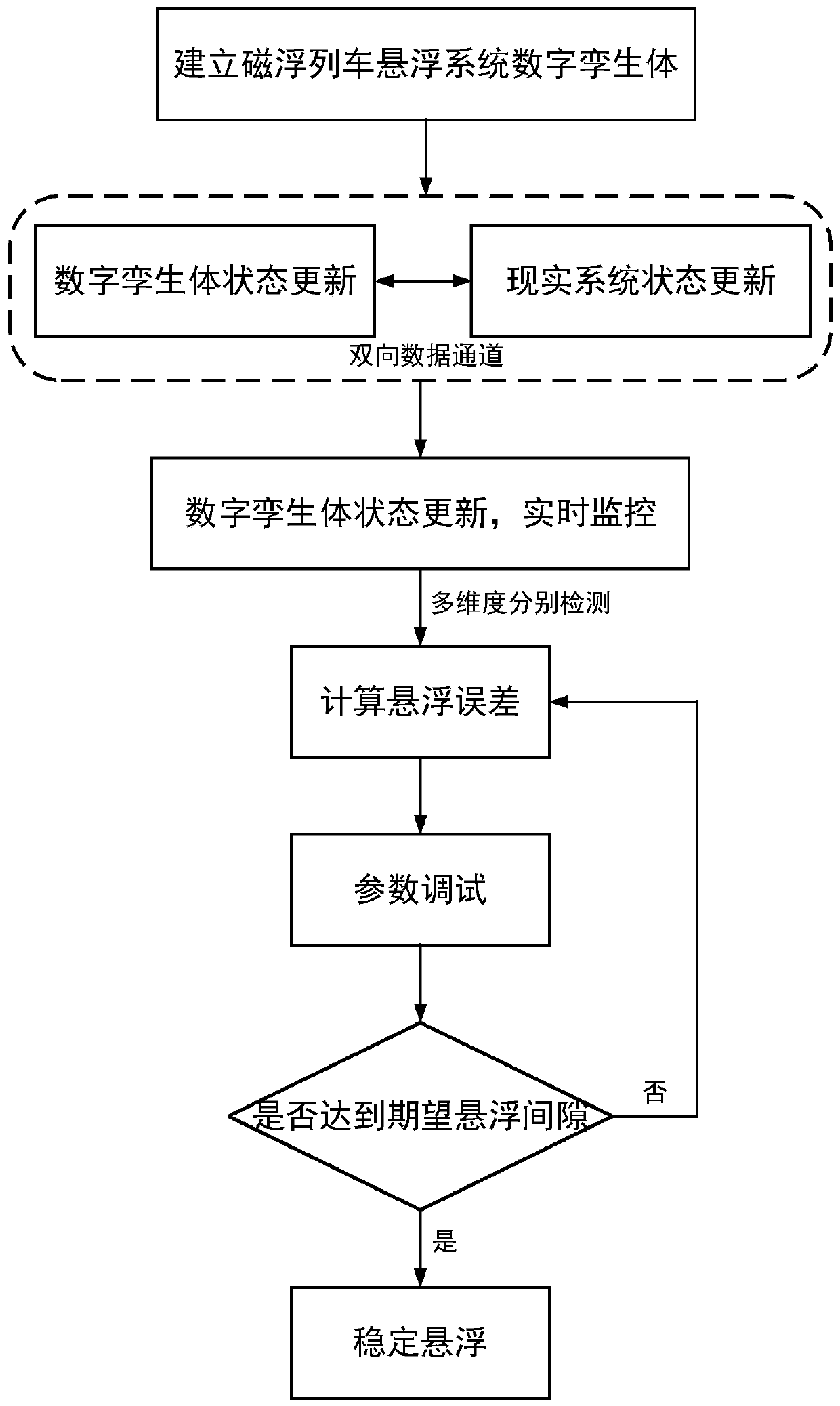

[0031] like figure 1 As shown, the present embodiment provides a method for debugging the suspension system of a maglev train based on digital twin technology, and the method includes the following steps:

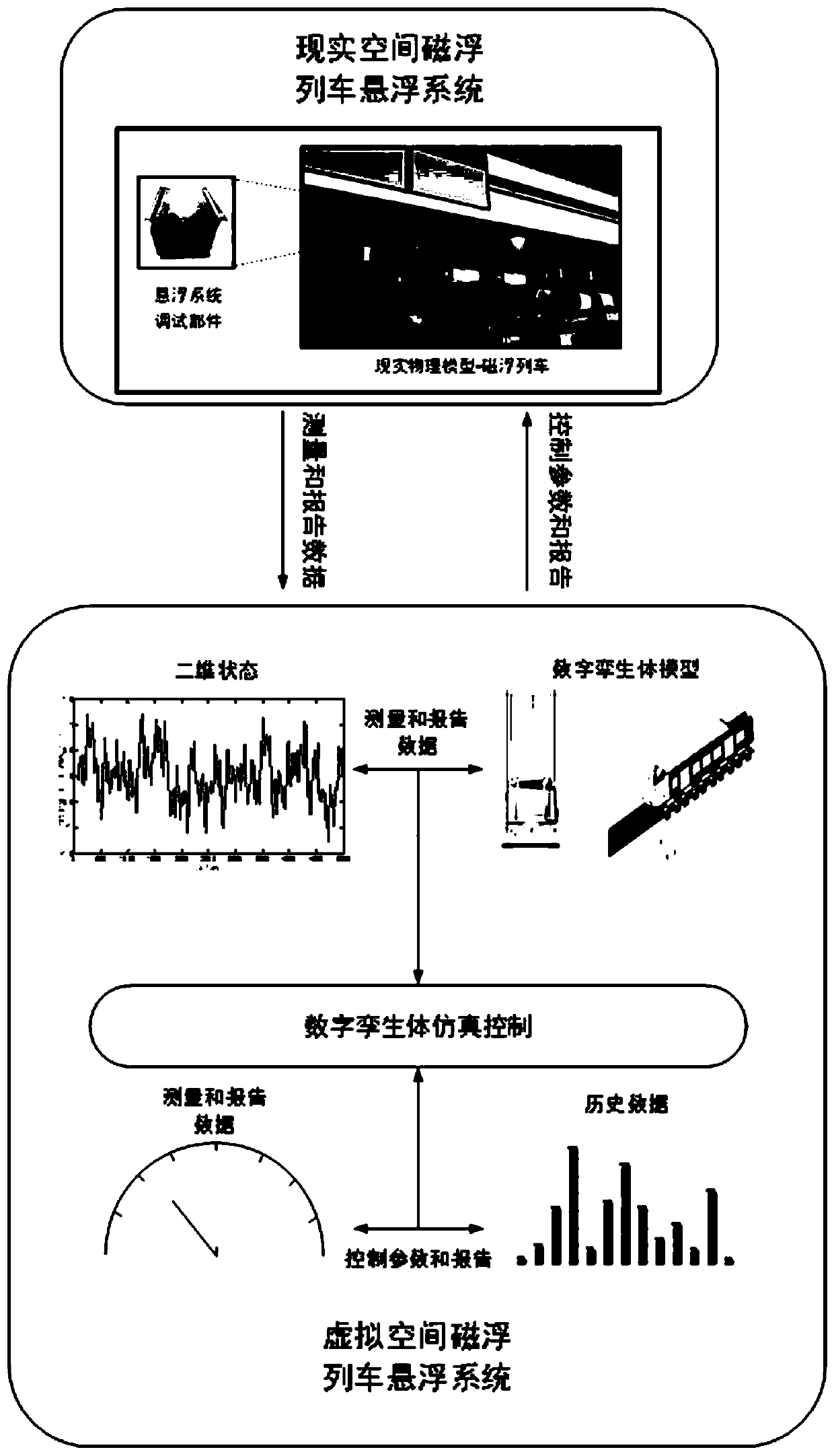

[0032] Digital twin construction step: build a digital twin of the maglev train suspension system, and communicate between the digital twin body and the maglev train suspension system;

[0033] Levitation data collection and sensing step: the maglev train levitation system collects and perceives levitation data through sensors, and transmits the levitation data to the digital twin in real time;

[0034] Suspension system debugging step: observe and debug the suspension state of the digital twin, thereby reacting to the suspension system of the maglev train.

[0035] The method is described in detail below:

[0036] 1. Digital twin

[0037] The digital twin is in the form of a multi-body dynamics model or a multi-physics model, which can be constructed using commercial mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com