Light-emitting logo assembly for automobile

A technology for logos and automobiles, applied in the field of auto parts, can solve the problems of bulkiness, large size of backlight module, flying debris, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

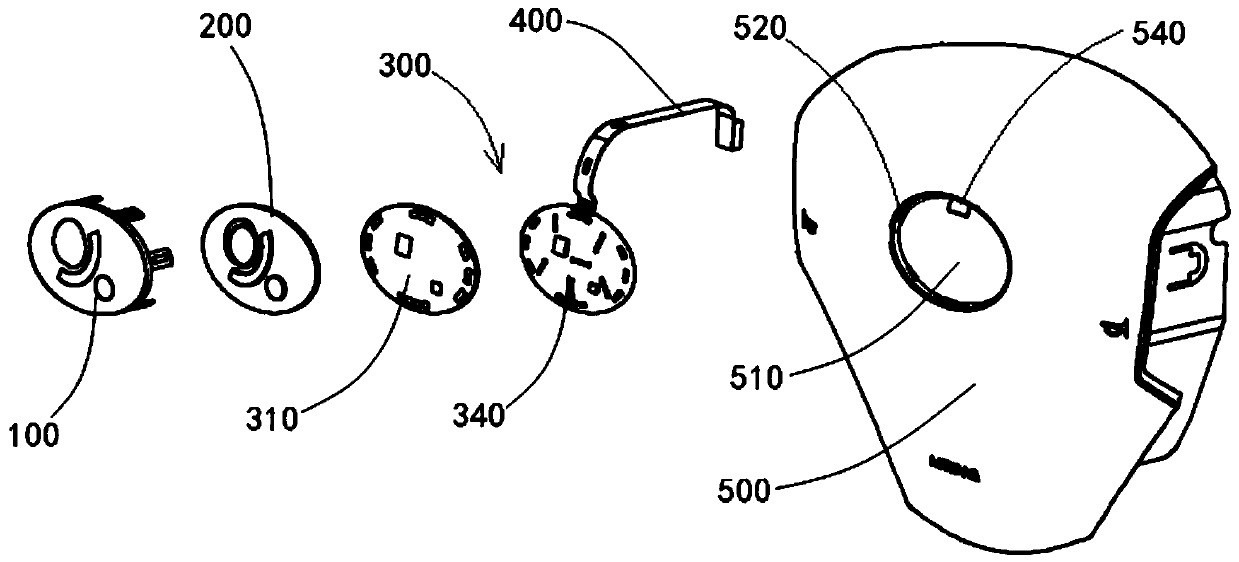

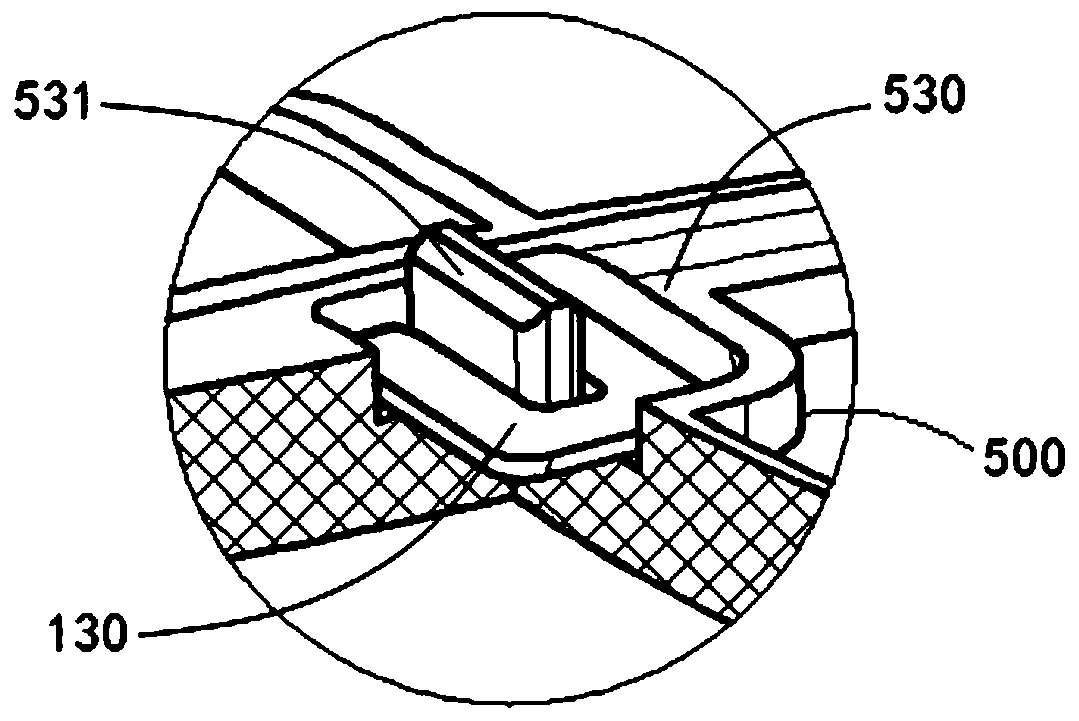

[0048] see figure 1 , shown in the figure is a luminous logo assembly for automobiles, including a logo cover 100, a logo body 200, a backlight module 300, a wire harness 400 and an airbag cover 500, and a logo installation recess is formed on the surface of the airbag cover 500 groove 510, the backlight module 300 is arranged in the logo installation groove 510 of the airbag cover 500, the logo body 200 is arranged in the logo installation groove 510 of the airbag cover 500 and is located on the surface of the backlight module 300, the logo cover 100 is pressed into the logo installation groove 510 of the airbag cover 500 and the logo body 200 and the backlight module 300 are pressed tightly. One end of the wiring harness 400 is connected with the backlight module 300, and the other end passes through the airbag cover 500 and connects with the backlight module 300. Automotive control system connection.

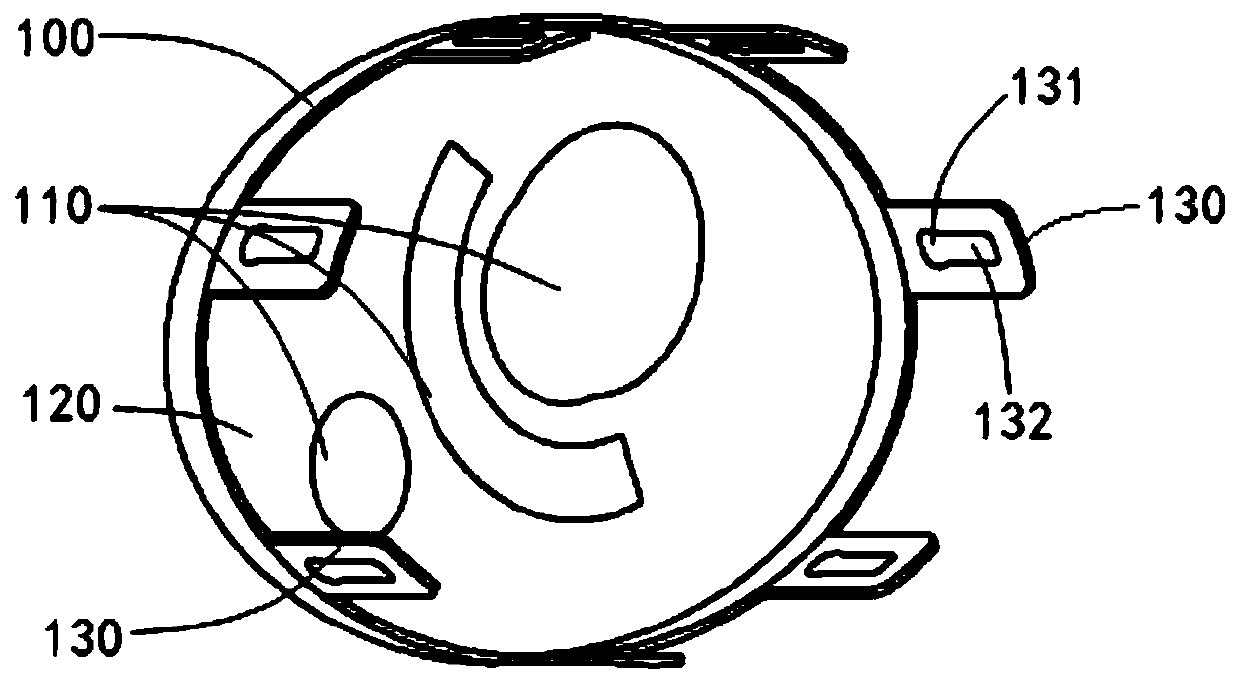

[0049] see figure 2 The shape of the logo cover plate 100 can be roun...

Embodiment 2

[0073] The luminous logo assembly for automobiles in this embodiment can meet the needs of designing traditional injection logos into luminous logos without changing the original effect of the logo. The structure of the luminous logo assembly for automobiles in this embodiment is the same as that of the automobile in Example 1 The structures of the luminous logo components are roughly the same, and the difference mainly lies in the structures of the logo cover plate 100a and the logo body 200a. see Figure 11 with Figure 12 The shape of the logo cover plate 100a can be circular, oval, strip-shaped, shield-shaped or other arbitrary shapes. The logo cover plate 100a is preferably made of a metal sheet material using a sheet metal forming process, and the metal sheet material is preferably aluminum, Steel (iron), copper, etc. In the middle of the logo cover plate 100a, the area corresponding to the part of the logo surface that needs to be illuminated is hollowed out to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com