Restoration agent for channel ecological improvement engineering

A restoration agent and ecological technology, applied in the restoration agent field of channel ecological renovation project, can solve the problems of poor ecological affinity, low porosity, hard texture of restoration structural materials, etc., to achieve good ecological affinity, high porosity, and maintain ecological The effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

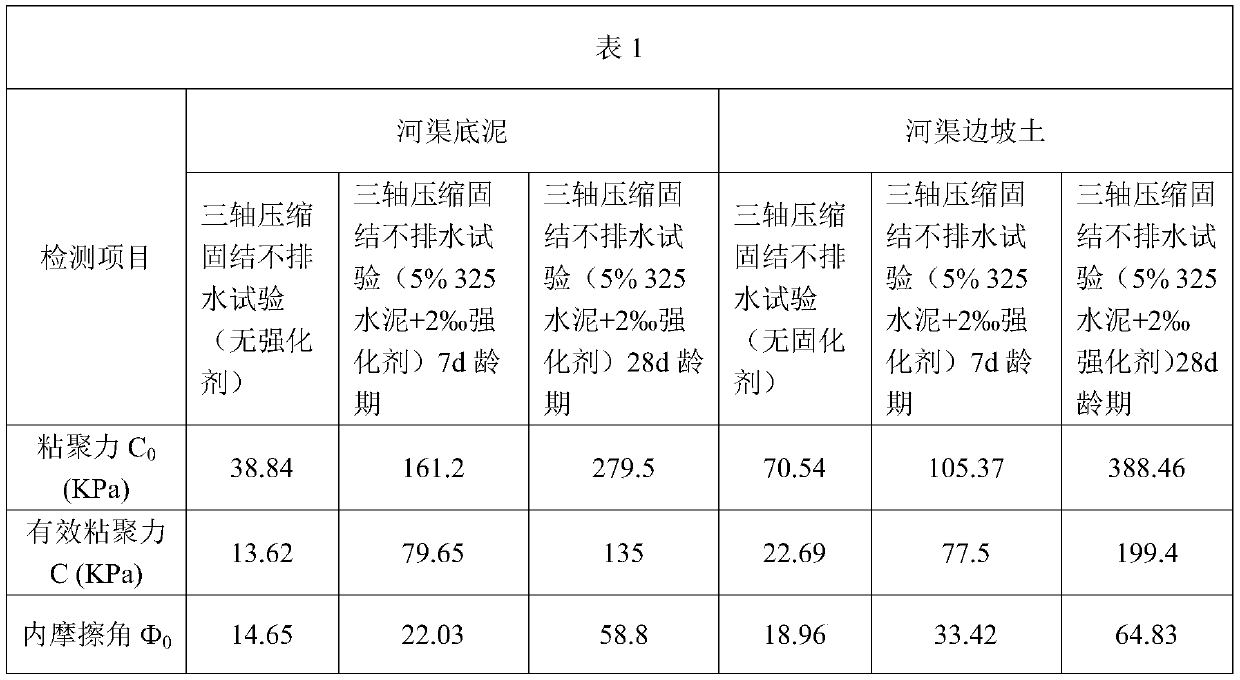

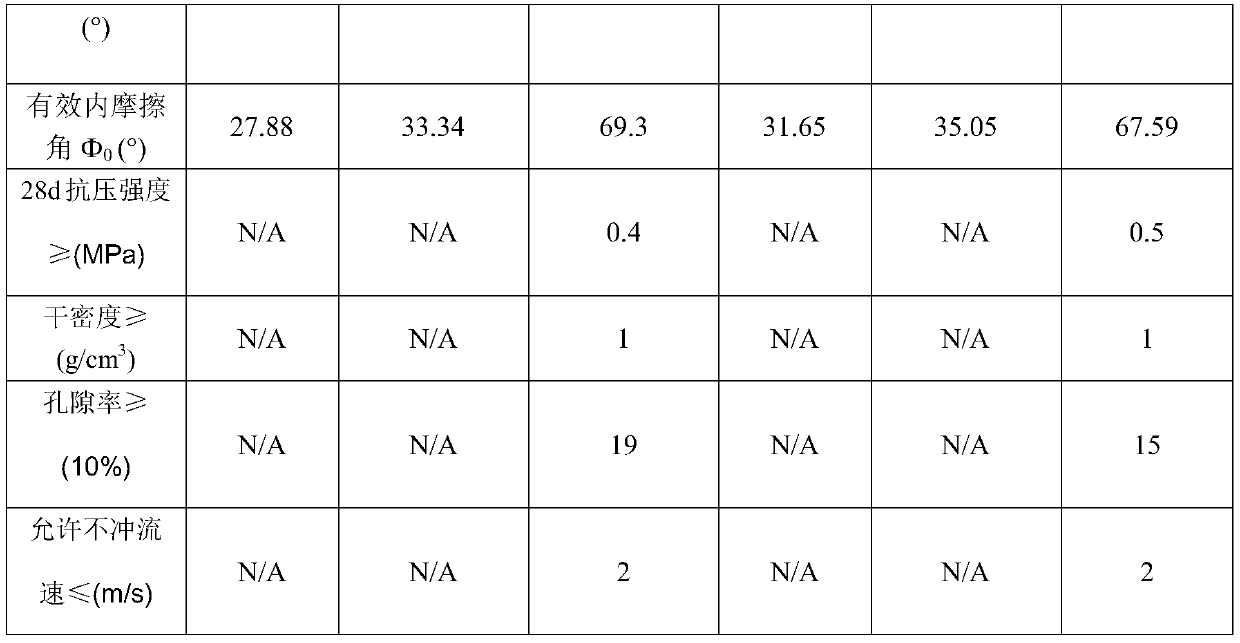

[0021] A restorative agent for channel ecological improvement project, which is prepared by stirring and mixing the following raw materials in parts by weight, including: 0.1 part of strong coagulant, 0.2 part of strengthening agent, 5 parts of cement, and 94.7 parts of clay. The preparation method of the channel restoration agent of the present invention comprises first stirring and mixing the raw materials according to the formula and forming them, and then air-drying and curing. The thickness of the solidified block is 15 cm, and the temperature for air-drying and curing is 20-32°C. The curing time is 7-30 days. The physical and chemical indicators after curing are shown in Table 1.

Embodiment 2

[0023] A restorative agent for canal ecological renovation project, which is prepared by stirring and mixing the following raw materials in parts by weight, including: 0.2 parts of strong coagulant, 0.2 part of strengthening agent, 5 parts of cement, and 94.6 parts of clay. The preparation method of the channel repairing agent of the present invention comprises firstly stirring and mixing the raw materials according to the formula and forming them, and then air-drying and curing. The thickness of the solidified block is 15 cm, and the temperature for air-drying and curing is 20-40°C. The curing time is 15-30 days.

Embodiment 3

[0025] A restorative agent for channel ecological renovation project, which is prepared by stirring and mixing the following raw materials in parts by weight, including: 0.1 part of strong coagulant, 0.3 part of strengthening agent, 7 parts of cement, and 92.7 parts of clay. The preparation method of the channel repairing agent of the present invention comprises firstly stirring and mixing the raw materials according to the formula and forming them, and then air-drying and curing. The thickness of the solidified block is 15 cm, and the temperature for air-drying and curing is 20-40°C. The curing time is 15-30 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com