A kind of supercritical fluid jigger

A supercritical fluid and dye jigger technology, which is applied in the processing of textile material carriers, textile material containers, liquid/gas/steam textile materials, etc., can solve the problem of low heat transfer efficiency of jacketed heat exchangers, dye dissolvers, etc. Difficult installation, high fabric tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

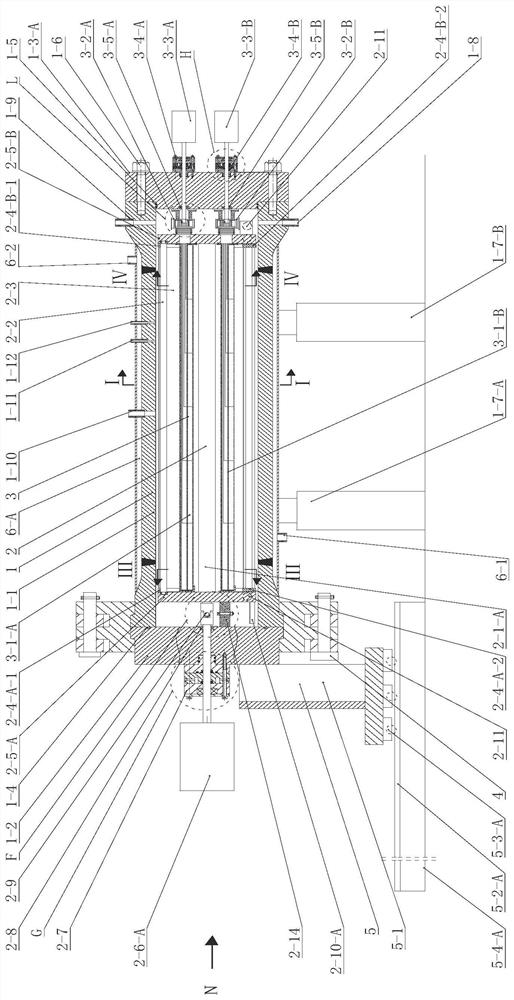

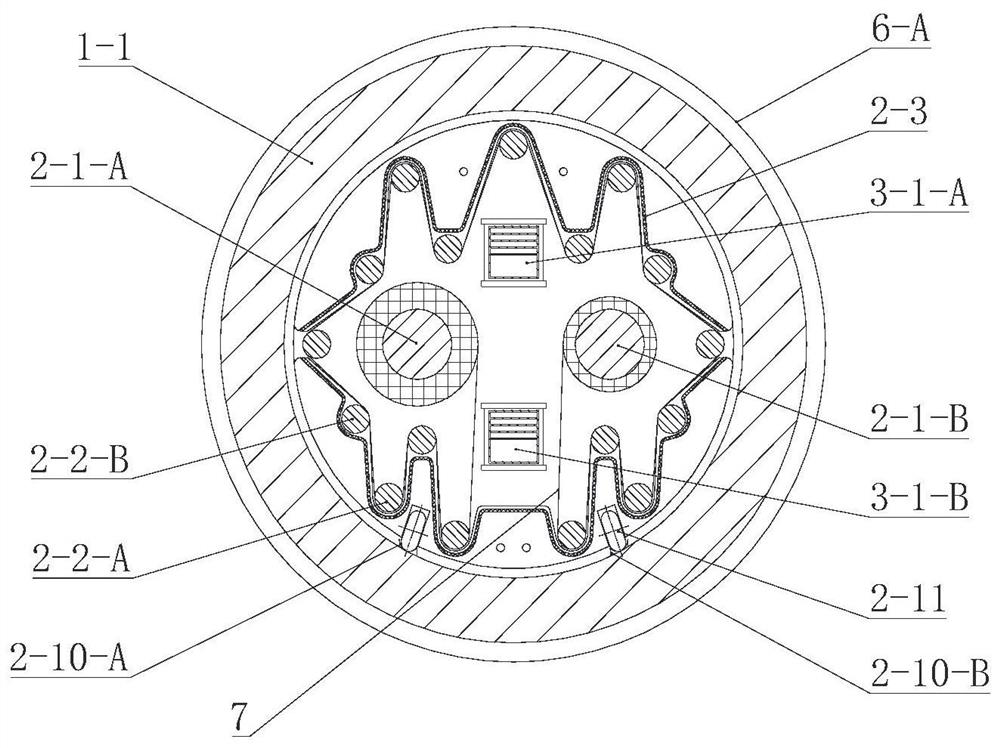

[0089] This embodiment discloses a supercritical fluid jigger with a small-diameter jigger structure that is difficult for people to enter and exit. The inner diameter of the cylinder body 1-1 is less than 800mm, and it has a non-quick opening cylinder cover 1-3-A, such as figure 1 , Figure 3-1 , Pic 4-1 , Figure 4-2 , Figure 5 , Figure 6-1 , Figure 6-2 , Figure 7-1 , Figure 7-2 , Figure 8-1 , Figure 9-1 , Figure 9-2 , Figure 9-3 , Figure 9-4 , Figure 10-1 , Figure 10-2 , Figure 10-3 , Figure 10-4 , Figure 10-5 , Figure 10-6 shown.

[0090] The supercritical fluid jigger with small diameter jigger structure is composed of jigger 1, jigger assembly 2, built-in dye dissolving circulation device 3, clamp opening and closing device 4, cloth roller sliding support device 5 and jacket heat exchanger 6 -A composition.

[0091] Such as figure 1 , the jigger vat 1 is mainly composed of a cylinder body 1-1, a quick opening cylinder cover 1-2, a non...

Embodiment 2

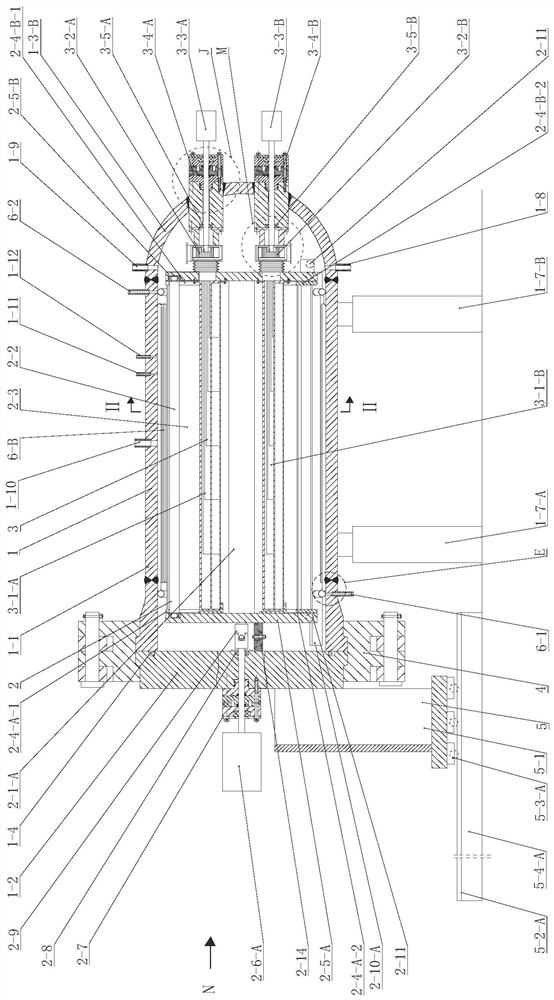

[0144] This embodiment discloses a supercritical fluid jigger with a large-diameter jigger structure that people can enter and exit. The inner diameter of the cylinder body 1-1 is greater than 800mm, and there is a non-detachable cylinder head 1-3-B, such as figure 2 , Figure 3-2 , Figure 3-3 , Pic 4-1 , Figure 4-2 , Figure 5 , Figure 6-1 , Figure 6-3 , Figure 7-1 , Figure 7-2 , Figure 8-2 , Figure 9-1 , Figure 9-2 , Figure 9-3 , Figure 9-4 , Figure 10-1 , Figure 10-2 , Figure 10-3 , Figure 10-4 , Figure 10-5 , Figure 10-6 Shown, the difference between its structure and embodiment 1 is: as figure 2 , the rear end part of the cylinder body 1-1 in this embodiment adopts the structure of the non-detachable cylinder head 1-3-B, and the non-detachable cylinder head 1-3-B is a hemispherical shell whose diameter is the same as that of the cylinder body 1-3-B. 1 is matched with the cylinder body 1-1 by welding, and the supercritical fluid mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com