Liquid-solid direct contact steam generator

A steam generator, direct technology, applied in the field of energy and environment, can solve the problems of huge investment in initial construction or renovation and upgrading of equipment, difficult to guarantee equipment life, and reduced recovery efficiency, etc., to achieve small size, reduce manufacturing and operating costs, avoid The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

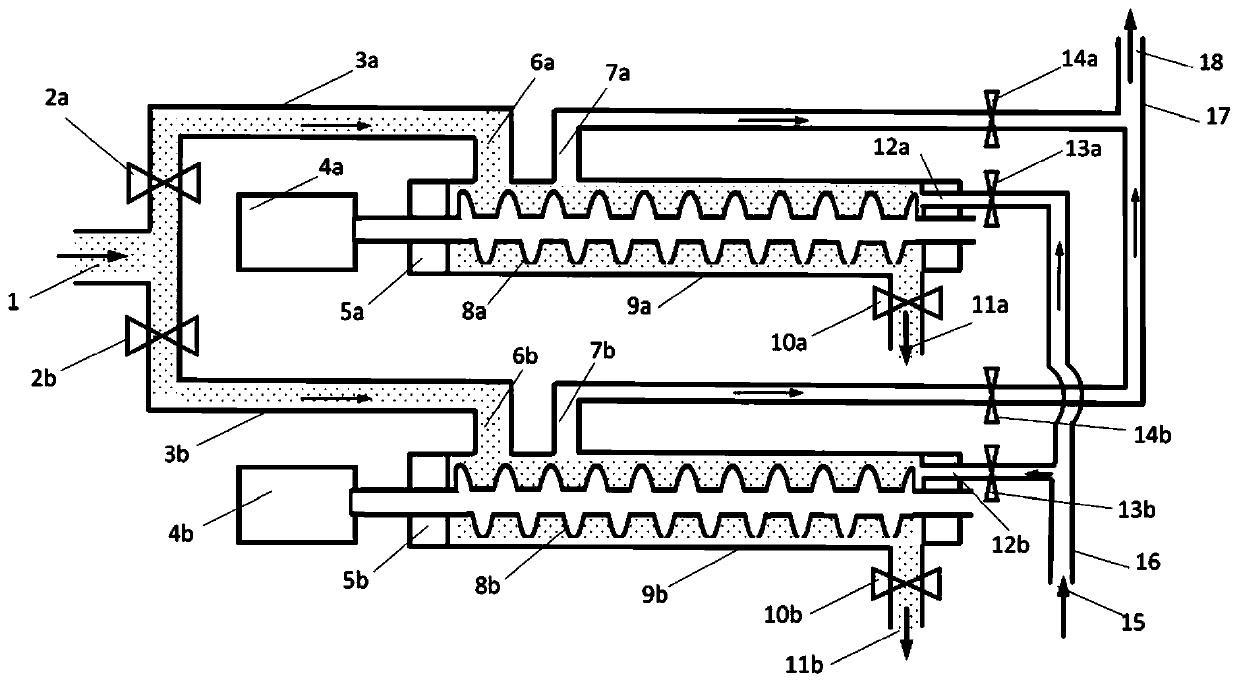

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] like figure 1 As shown, the steam generator in direct contact with liquid and solid according to the present invention includes arranging a plurality of pressure pipes with screw conveyors, and each pressure pipe is respectively connected with solid particle pipes, steam pipes and liquid pipes, and the steam pipes are located at Between the solid particle pipeline and the liquid pipeline, the opposite end of the solid particle pipeline on the pressure pipeline is provided with a particle discharge outlet, and valves are respectively arranged on each solid particle pipeline, steam pipeline, liquid pipeline and particle discharge outlet. The solid particles flow through the solid particle pipeline, the pressure pipeline and the particle discharge port to form a solid particle conveying channel, and the steam pipeline, the pressure pipeline and the liquid pipeline form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com