Bridge construction device based on thermal cycle

A bridge construction and thermal cycle technology, applied to steam engine installations, mechanically driven excavators/dredgers, cranes, etc., can solve the problems of inability to meet construction requirements in many aspects, huge construction machinery, low degree of integration, etc., to achieve Avoid cold source loss, improve work efficiency, and have multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

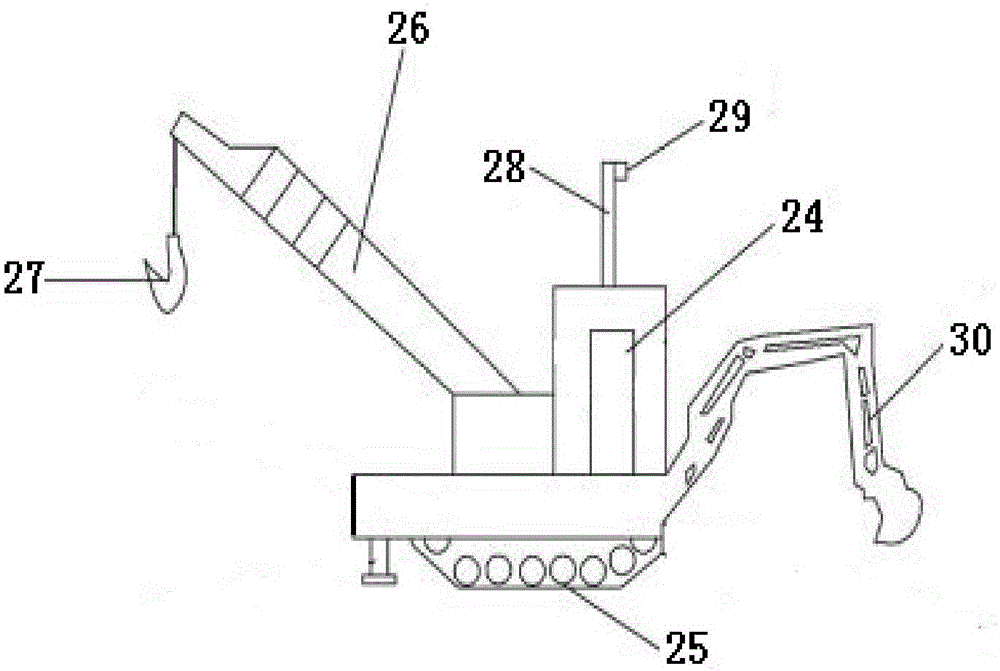

[0021] Such as figure 1 A thermal cycle-based bridge construction device shown includes an operating room 24, a crawler belt 25, a boom 26, a hook 27, a pole 28, a lighting lamp 29, an excavating arm 30 and an engine energy recovery device, and the lighting lamp 29 is connected with the operating room 24 through the vertical rod 28, the suspension hook 27 is fixedly connected on one end of the construction device through the boom 26, and the excavating arm 30 is arranged at the other end; the crawler belt 25 is driven by the engine 2.

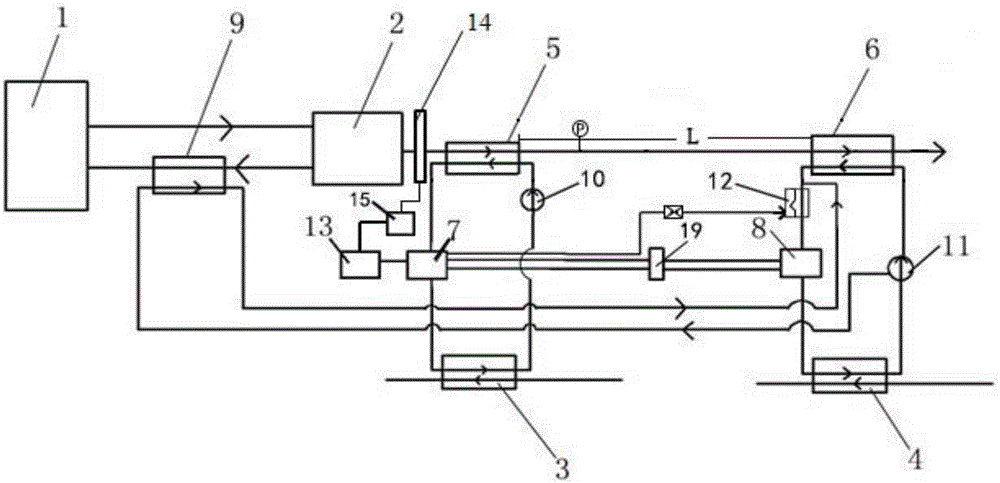

[0022] Such as figure 2 As shown, the engine energy recovery device is used to recover the energy of the exhaust gas of the engine 2, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency conversion Device 15 and back pressure regulating blower 14. The radiator 1 is connected with the engine 2, an...

Embodiment 2

[0032] Such as figure 1 A thermal cycle-based bridge construction device shown includes an operating room 24, a crawler belt 25, a boom 26, a hook 27, a pole 28, a lighting lamp 29, an excavating arm 30 and an engine energy recovery device, and the lighting lamp 29 is connected with the operating room 24 through the vertical rod 28, the suspension hook 27 is fixedly connected on one end of the construction device through the boom 26, and the excavating arm 30 is arranged at the other end; the crawler belt 25 is driven by the engine 2.

[0033] Such as figure 2As shown, the engine energy recovery device is used to recover the energy of the engine exhaust, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency converter 15 and back pressure regulating fan 14. The radiator 1 is connected with the engine 2, and the radiator 1 transfer...

Embodiment 3

[0043] Such as figure 1A thermal cycle-based bridge construction device shown includes an operating room 24, a crawler belt 25, a boom 26, a hook 27, a pole 28, a lighting lamp 29, an excavating arm 30 and an engine energy recovery device, and the lighting lamp 29 is connected with the operating room 24 through the vertical rod 28, the suspension hook 27 is fixedly connected on one end of the construction device through the boom 26, and the excavating arm 30 is arranged at the other end; the crawler belt 25 is driven by the engine 2.

[0044] Such as figure 2 As shown, the engine energy recovery device is used to recover the energy of the engine exhaust, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency converter 15 and back pressure regulating fan 14. The radiator 1 is connected with the engine 2, and the radiator 1 transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com