Sealing equipment of grate cooler transmission mechanism for cement production

A transmission mechanism and sealing equipment technology, applied in lighting and heating equipment, processing discharged materials, furnaces, etc., can solve the problems of powder and other impurities that cannot be cleaned, so as to avoid accumulation on the outer surface, increase controllability, and improve cleaning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

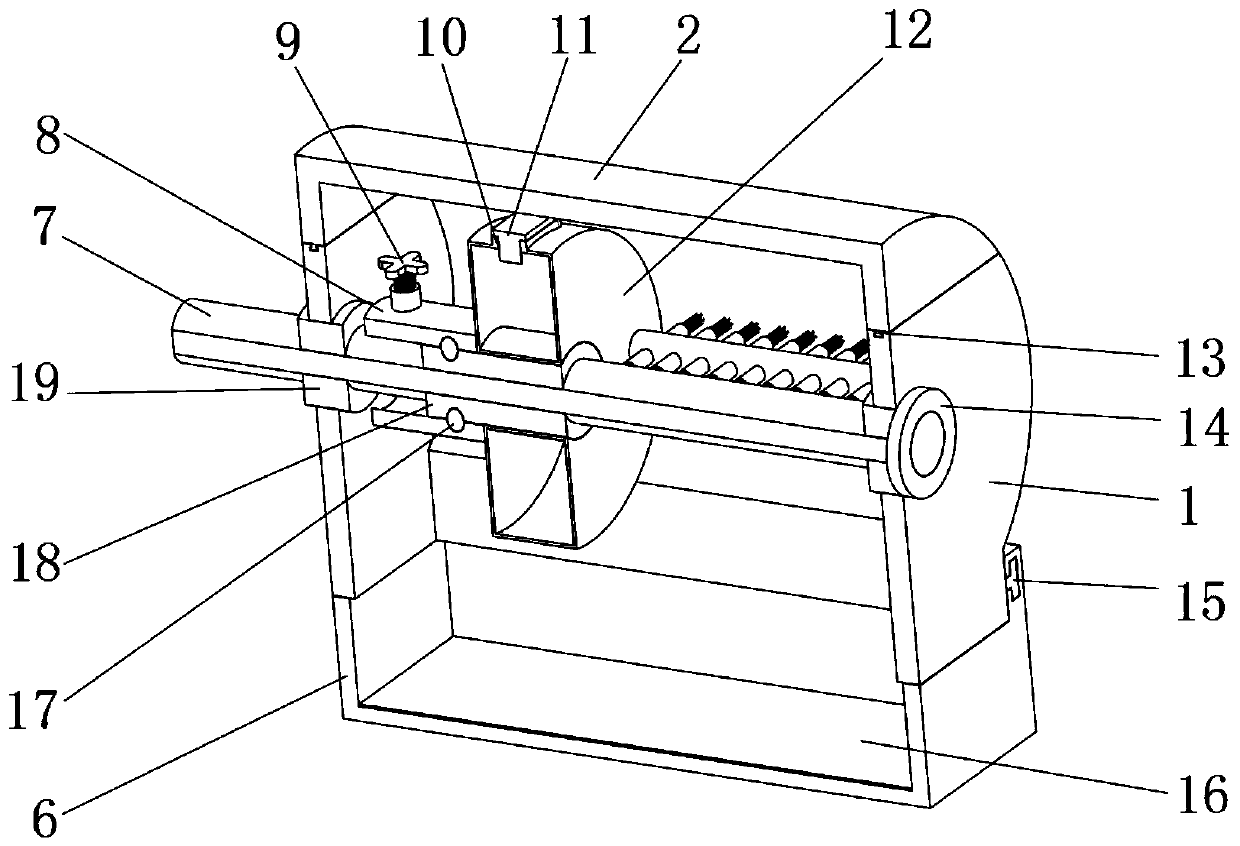

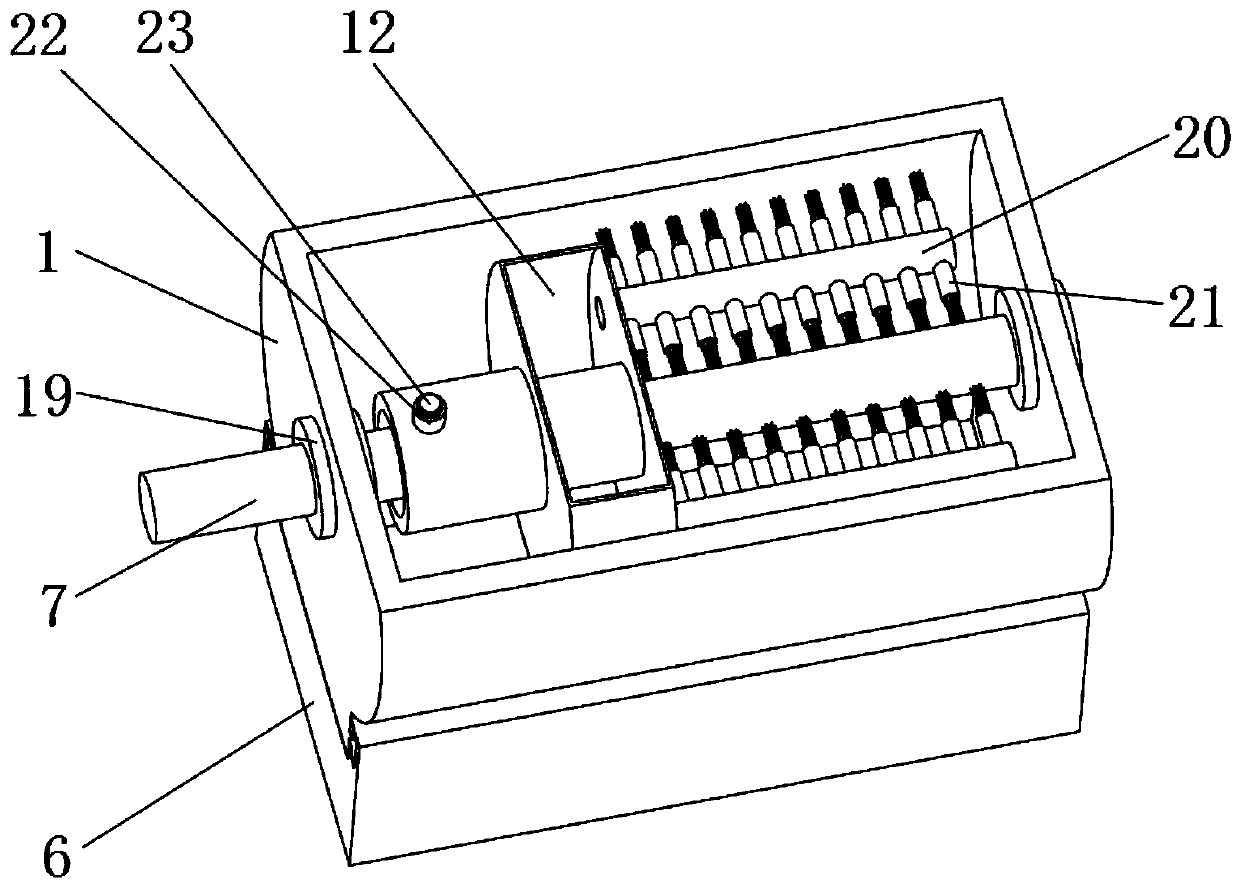

[0033] A sealing device for the transmission mechanism of a grate cooler for cement production, such as Figure 1-4 As shown, it includes a sealed chamber 1 fixed to the outer wall of one side of the equipment casing 3 by bolts and a fixing seat 18 fixed to the outer wall of the transmission shaft 7 by a top screw; the inner wall of one side of the sealed chamber 1 is fixed with the first bearing seat A waterproof bearing 14, and the inner wall of the other side of the sealed chamber 1 is fixed with a second waterproof bearing 19 through the second bearing seat, and the first waterproof bearing 14 and the second waterproof bearing 19 are all installed on the outer wall of the transmission shaft 7; The outer wall of the fixed seat 18 is slidably connected with a water storage chamber 12, and the outer wall of one side of the water storage chamber 12 is welded with two guide tubes 20, and the outer walls of both sides of the two guide tubes 20 are welded with several evenly distr...

Embodiment 2

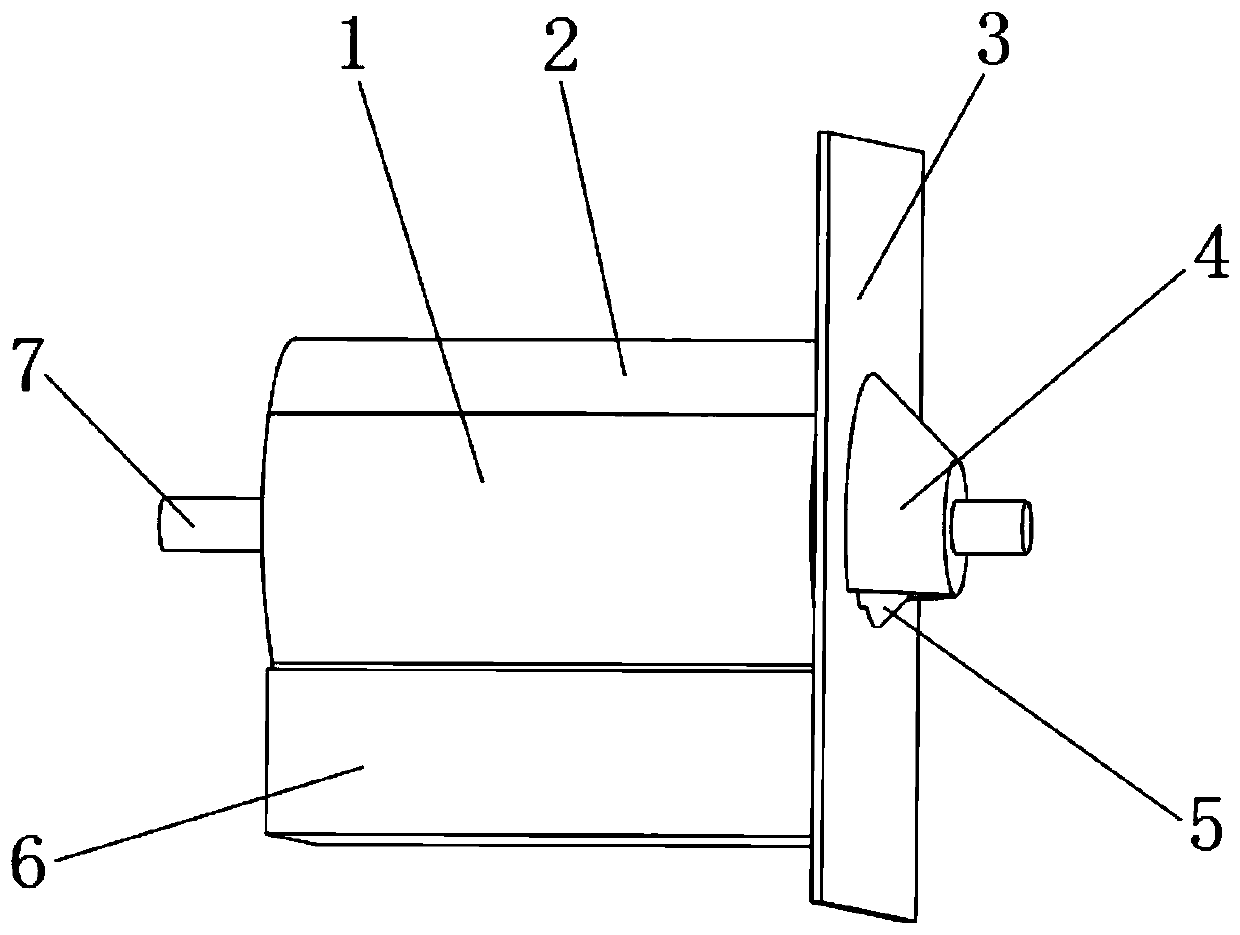

[0042] A sealing device for the transmission mechanism of a grate cooler for cement production, such as figure 1 , Image 6 As shown, in order to further prevent dust; this embodiment makes the following improvements on the basis of embodiment 1: one side of the outer wall of the device casing 3 is welded with an outer barrier cover 4, and the same side of the outer wall of the device casing 3 is welded with an inner barrier Cover 5, the outer blocking cover 4 is arranged on the outside of the inner blocking cover 5, one side inner wall of the outer blocking cover 4 and one side inner wall of the inner blocking cover 5 are all slidably connected to the outer wall of the transmission shaft 7; by setting the outer blocking cover 4 and the inner The blocking cover 5 can effectively block the internal dust from diffusing to the outside.

[0043] In order to reduce internal dust accumulation; such as Image 6 As shown, the bottom outer wall of the inner blocking cover 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com