Old Wire Stripper

A technology of stripping machine and old wires, applied in the direction of circuits, electrical components, electronic waste recycling, etc., can solve the problems of single wire stripping machine mechanism, insufficient wire clamping force, and incomplete peeling of the skin of the wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

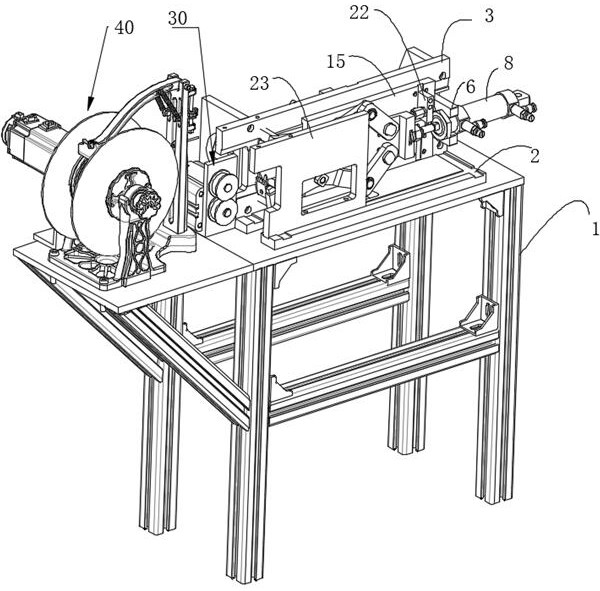

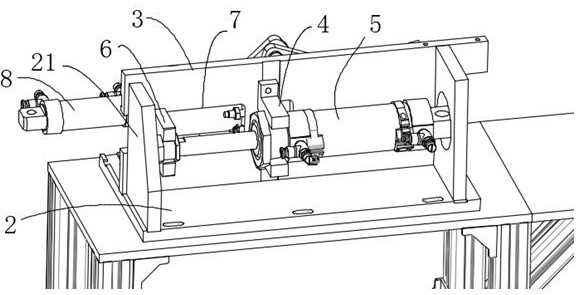

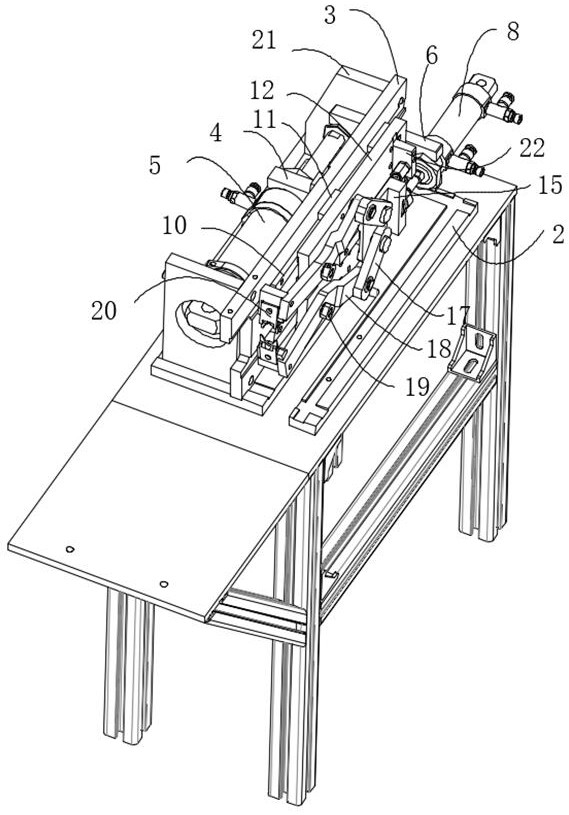

[0023] Embodiment: old electric wire stripping machine, constitutes as figure 1 As shown, including the base 1, the base 1 is provided with a positioning plate 2, the side of the positioning plate 2 near the moving plate 6 is provided with a limit block 21, the positioning plate 2 is provided with an upright plate 3, and the upright plate 3 A connecting rod limiting block 22 is provided on the side close to the connecting rod fixing seat 15, and a cylinder fixing seat 4 is provided on the rear side of the upright plate 3, and the first cylinder 5 is clamped on the cylinder fixing seat 4, and the first cylinder 5 The extension end is provided with a movable plate 6, such as figure 2 As shown, the limit block 22 can effectively limit the stroke of the first cylinder 5, avoiding the failure caused by the first cylinder 5 exceeding its own stroke; the upright plate 3 is provided with a rectangular gap 7, and the moving plate 6 is arranged on the rectangular gap 7, the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com