Weighing sensor assembling device

A technology of a load cell and an assembly device, applied in the field of load cells, can solve problems such as inconvenient operation of workers, and achieve the effects of ensuring accuracy, reducing the difficulty of assembly operations, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

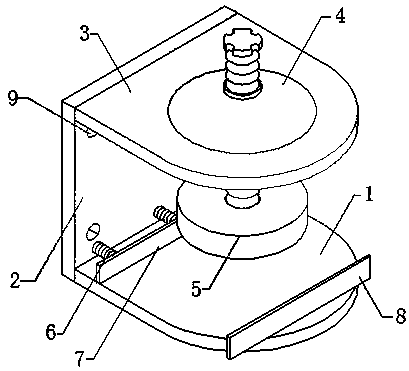

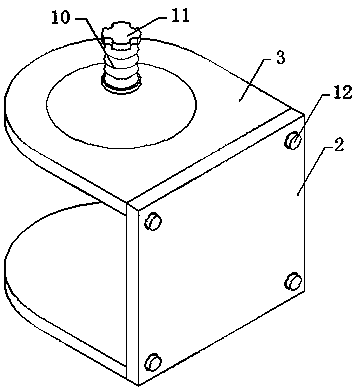

[0022] Such as Figure 1-Figure 3 As shown, a load cell assembly device includes a mounting back plate 2, the bottom of the front of the mounting back plate 2 is fixed with a first horizontal plate 1, and the top of the first horizontal plate 1 is fixed with a horizontal limit mechanism. The top of the front of the plate 2 is fixed with a second horizontal plate 3, and the middle part of the second horizontal plate 3 is threaded to connect the vertical limit mechanism. The horizontal limit mechanism includes a fixed horizontal plate fixed on the top side of the first horizontal plate 1 8 and the movable horizontal plate 7 that is slidably arranged on the other side of the top of the first horizontal plate 1, the back side of the movable horizontal plate 7 is movably connected with the installation backplane 2 through the fixed compression spring 6, which can adapt to the weighing of different shapes and specifications The sensor is easy to use, and at the same time greatly red...

Embodiment 2

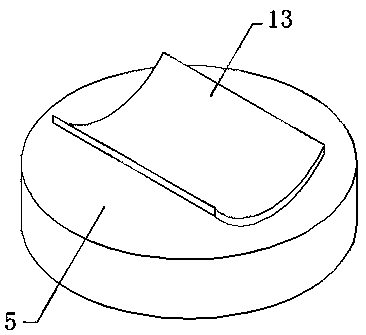

[0024] On the basis of Embodiment 1, such as Figure 1-Figure 3 As shown, the bottom of the cylindrical limiter 5 is fixed with a rubber suction cup 13, which is convenient for more stable limit and fixation of the load cell and is convenient for assembly. The middle part of the top and the middle part of the bottom of the second horizontal plate 3 are fixed Boss 4, two bosses 4 are threaded through connection with adjusting threaded rod 10, play the role of protecting adjusting threaded rod 10, avoid adjusting threaded rod 10 from getting rusty and corroded, unusable, install the four sides of the front of back plate 2 Mounting holes 9 are provided at the corners, and screws 12 are threaded inside the four mounting holes 9, which is convenient for quick installation and saves time.

[0025] It should be noted that the present invention is a load cell assembly device. When in use, the load cell is first placed on the top of the first horizontal plate 1, and the movable horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com