An automatic assembly device for LED lights

An automatic assembly device and LED lamp technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of insufficient technology, reduced LED lamp assembly efficiency, cumbersome replacement and loading and unloading, etc., to prevent distortion and damage, avoid Loose, adaptable effect with a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

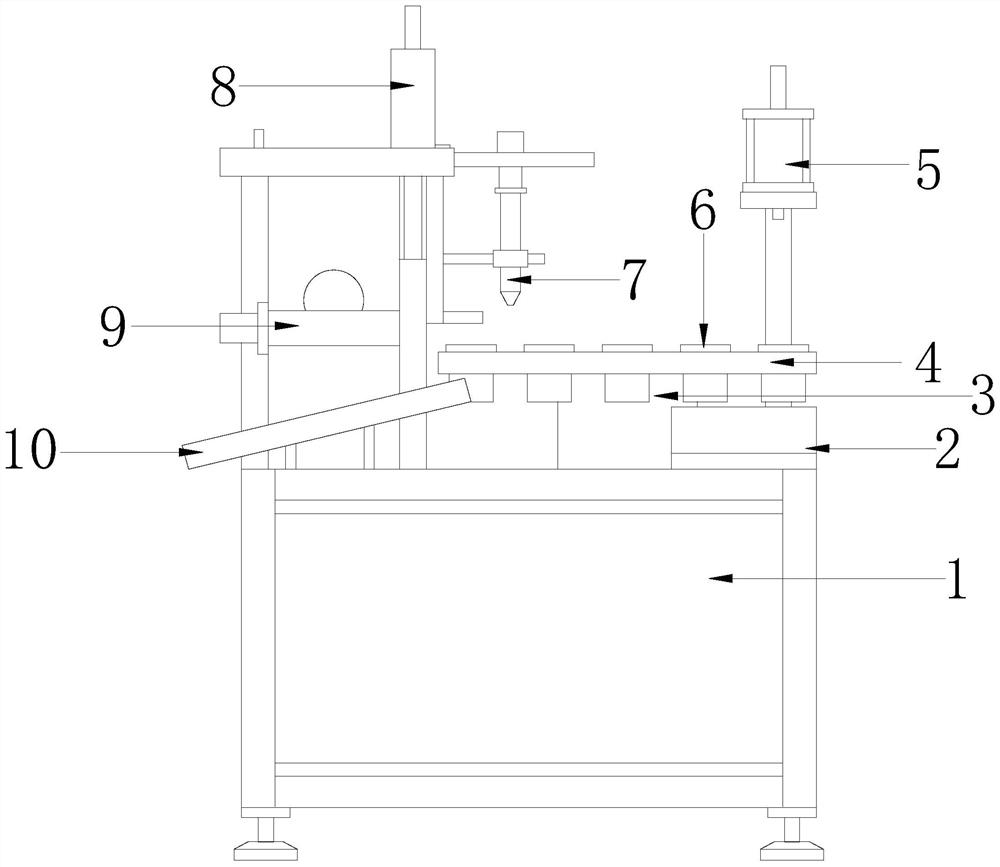

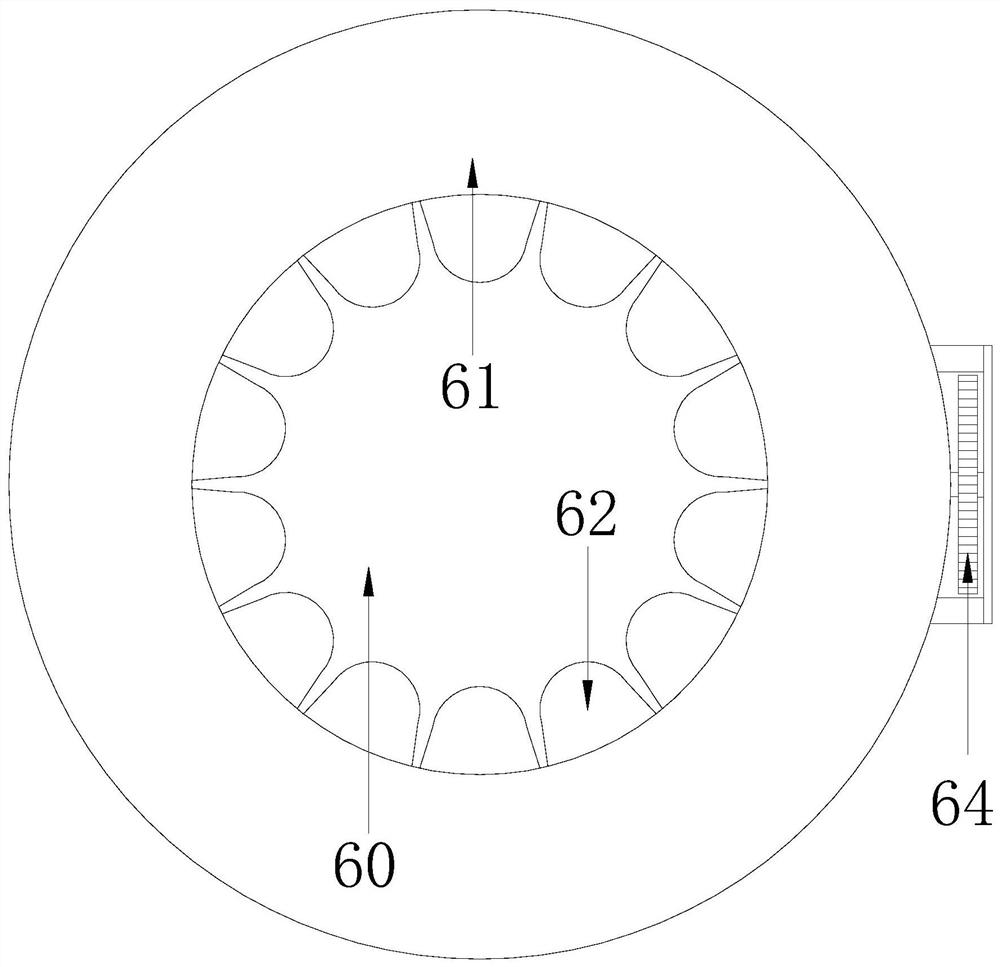

[0043] see figure 1, the present invention provides a technical solution for an automatic LED lamp assembly device: its structure includes an organism 1, a controller 2, a rotating pan platform 3, a disc 4, a pre-pressing mechanism 5, an LED lamp body placement cylinder 6, and a glue dispensing mechanism 7 , a manipulator 8, a lampshade placement frame 9, and a lamp removal board 10, a controller 2 is fixed on the body 1, and a lamp removal board 10 connected to the body 1 is provided on one side of the controller 2, and the lamp removal board 10 Afterwards, a manipulator 8 and a lampshade placement frame 9 connected to the body 1 are provided, and the manipulator 8 is also connected to the dispensing mechanism 7, which is located above the disc 4, and the disc 4 passes through the rotating platform 3. Connected to the body 1, the disc 4 is evenly distributed with LED lamp body placement tubes 6, and the body 1 is also equipped with a pre-pressing mechanism 5;

[0044] see ...

Embodiment 2

[0051] see figure 1 , the present invention provides a technical solution for an automatic LED lamp assembly device: its structure includes an organism 1, a controller 2, a rotating pan platform 3, a disc 4, a pre-pressing mechanism 5, an LED lamp body placement cylinder 6, and a glue dispensing mechanism 7 , a manipulator 8, a lampshade placement frame 9, and a lamp removal board 10, a controller 2 is fixed on the body 1, and a lamp removal board 10 connected to the body 1 is provided on one side of the controller 2, and the lamp removal board 10 Afterwards, a manipulator 8 and a lampshade placement frame 9 connected to the body 1 are provided, and the manipulator 8 is also connected to the dispensing mechanism 7, which is located above the disc 4, and the disc 4 passes through the rotating platform 3. Connected to the body 1, the disc 4 is evenly distributed with LED lamp body placement tubes 6, and the body 1 is also equipped with a pre-pressing mechanism 5;

[0052] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com