Special-shaped ceramic 3D printer

A 3D printer and ceramic technology, which is applied in the field of special-shaped ceramic 3D printers, can solve the problems of low melting efficiency, slow work efficiency, and poor adaptability of 3D printers, and achieve the effects of accelerating melting speed, improving work efficiency, and improving melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

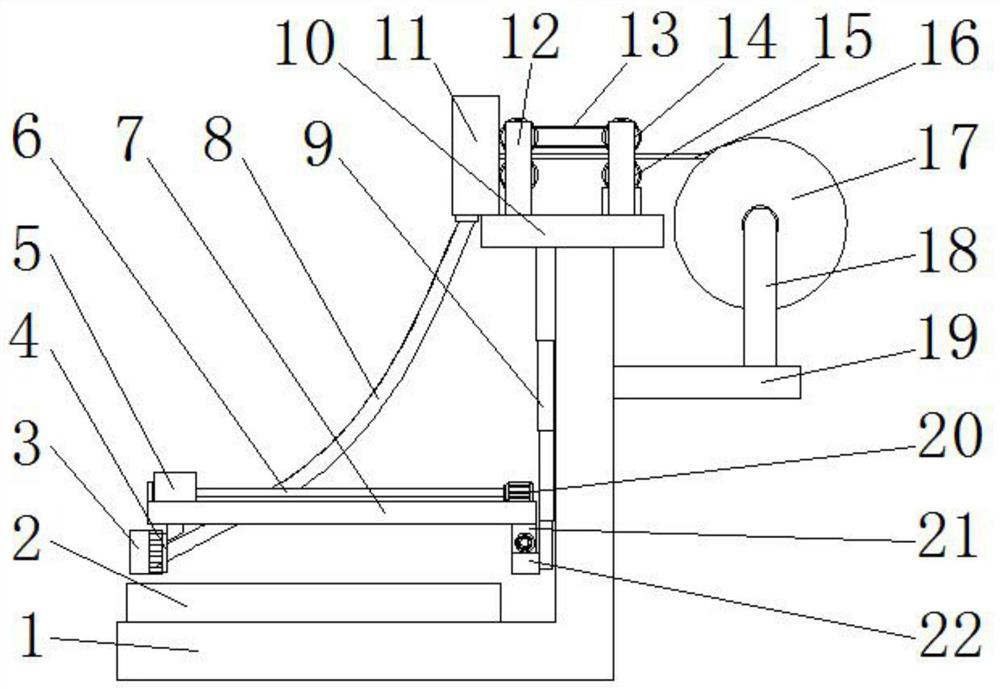

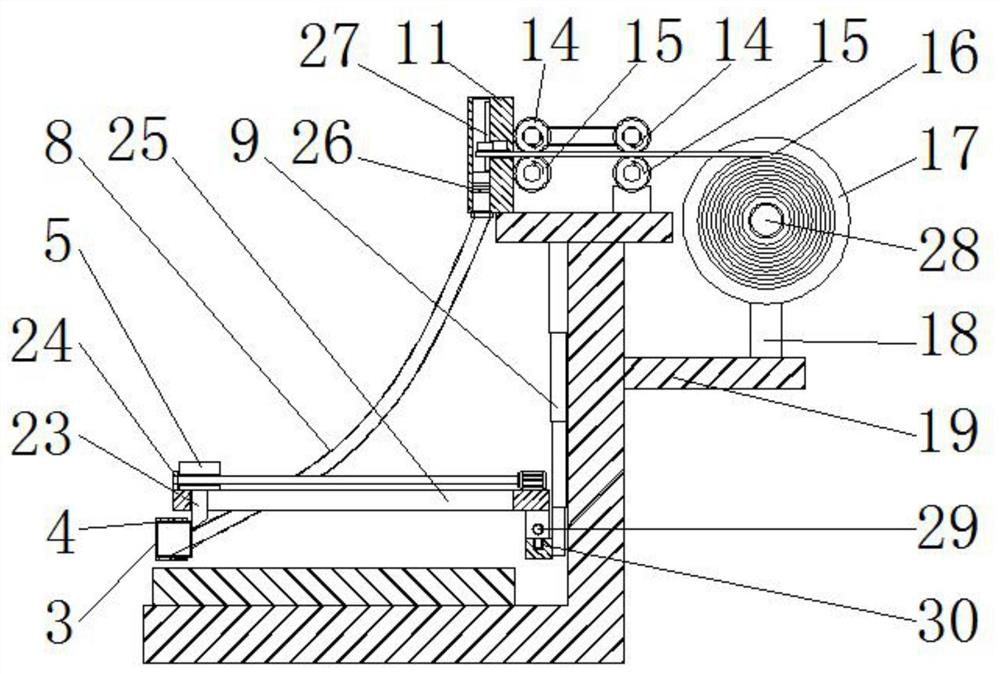

[0034] Such as figure 1 and figure 2 A special-shaped ceramic 3D printer shown includes a mounting base 1, a printing table 2, a printing nozzle, an X-axis adjustment mechanism, a Y-axis adjustment mechanism, a telescopic mechanism, and a feeding mechanism. The printing table 2 is horizontally connected to the mounting base 1, the X-axis adjustment mechanism, Y-axis adjustment mechanism and telescopic mechanism are connected one by one, and the printing nozzle is located above the printing table 2 and connected with the X-axis adjustment mechanism, Y-axis adjustment mechanism or telescopic mechanism , the feeding mechanism includes a main part installed on the mounting base 1 and a feeding pipe 8 connected between the main part and the printing nozzle;

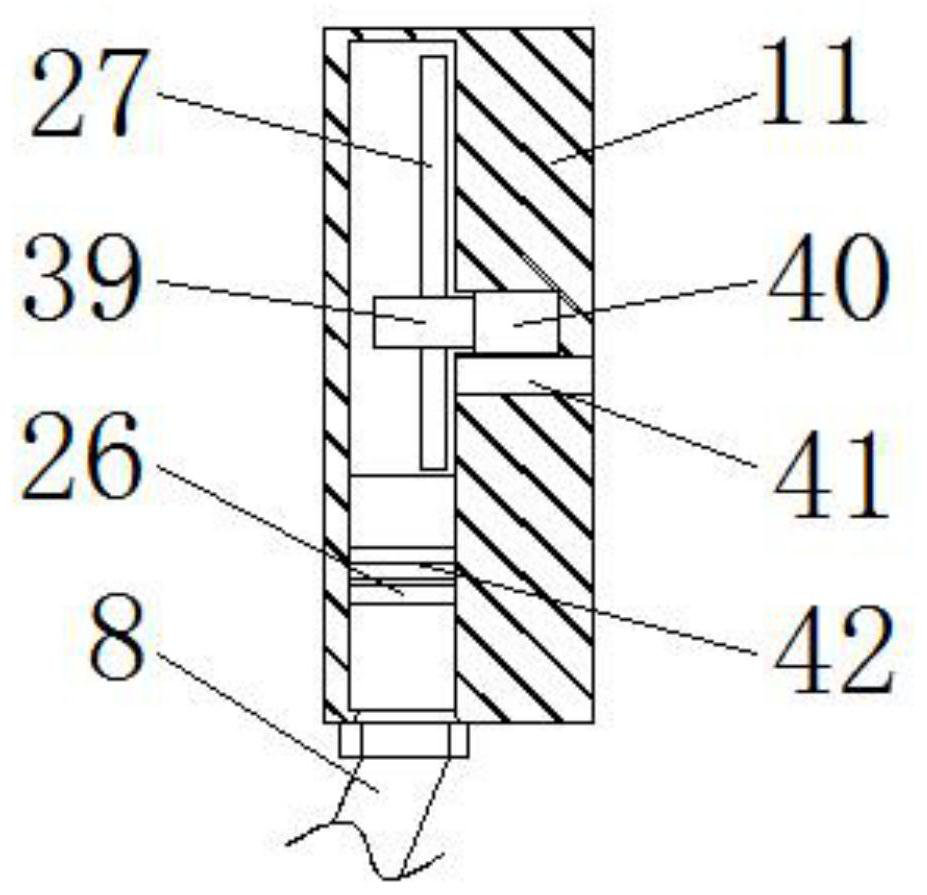

[0035] The main part of the feeding mechanism includes a raw material reel 17, a feed roller group and a raw material processing box 11, the raw material reel 17 is rotatably connected to the side of the mounting seat 1 faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com