3D (three-dimensional) printing platform with adjustable angle

A 3D printing and adjustable technology, applied in the direction of processing platform/substrate, manufacturing auxiliary device, processing drive device, etc., can solve problems such as poor bonding between the model and the platform, nozzle damage, edge warping, etc., to achieve precise control and Effects of automation, surface accuracy improvement, and residual height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

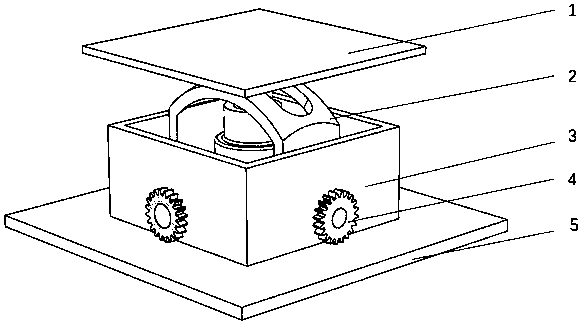

[0021] Such as figure 1 As shown, the specific implementation includes a platform 1, a swing bogie 2, a casing 3, a base 5, a connecting rod 6, a center bogie 7, a right connecting plate 8, a first gear shaft 9, a second gear shaft 10, a support shaft 11, The left connecting plate 12; the internal mechanisms are all fixed on the shell 3, and the shell 3 is fixed on the base 5.

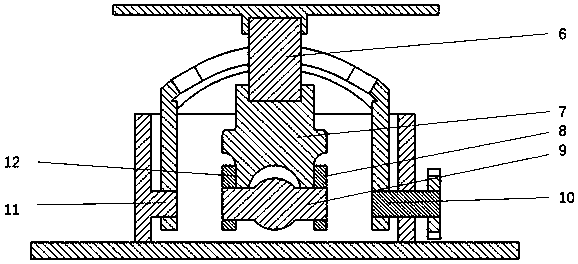

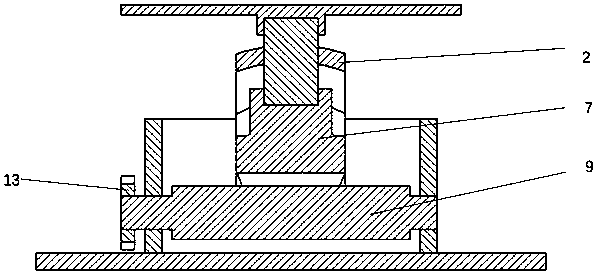

[0022] Such as figure 2 with image 3 As shown, the first gear shaft 9 is hinged horizontally between the side plates on both sides of the housing 3 in one direction, and branch shafts are symmetrically fixed on both sides of the center of the first gear shaft 9. The two branch shafts are coaxially arranged and perpendicular to the first gear shaft. The axial direction of a gear shaft 9 makes the first gear shaft 9 and two branch shafts form a cross shaft structure, the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com