Energy-saving boiler capable of rapidly settling dust

A dust reduction and boiler technology, applied in the field of boiler energy saving, can solve the problems of lower heat transfer efficiency, lower heat utilization rate, and easy adhesion, etc., and achieve the effects of smooth flow, high heat energy utilization efficiency, and prevention of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

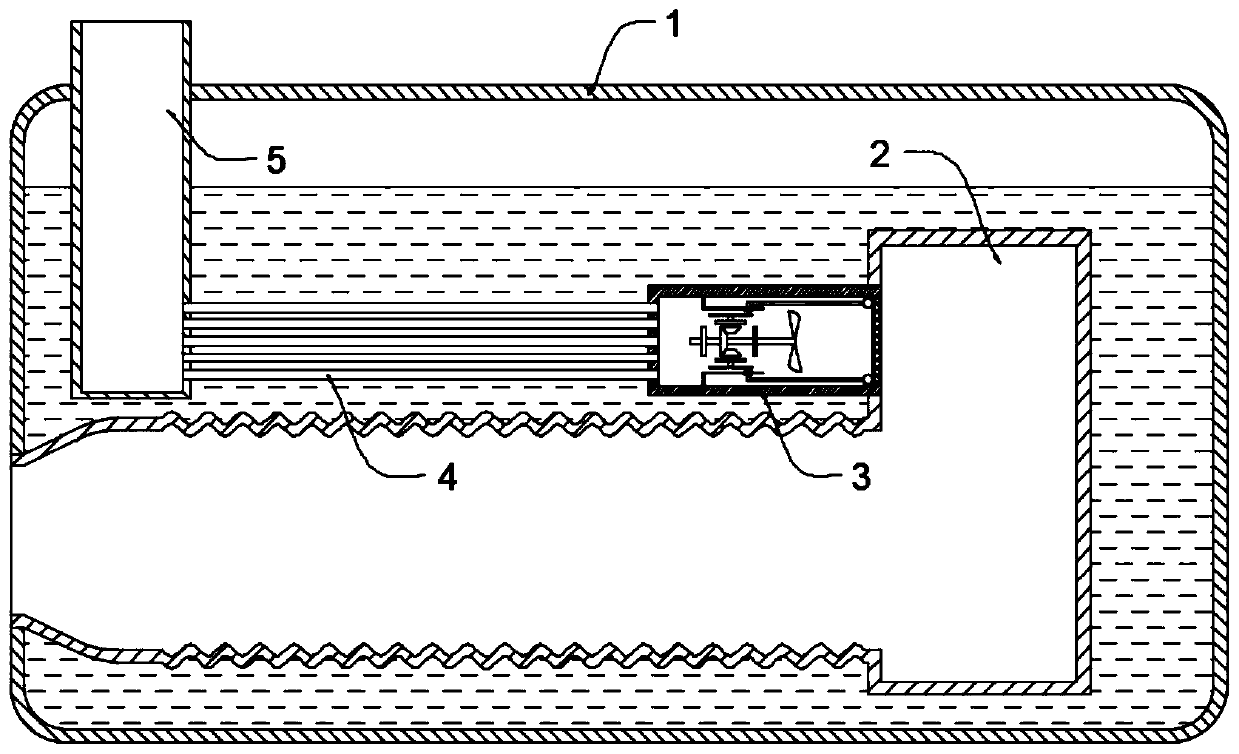

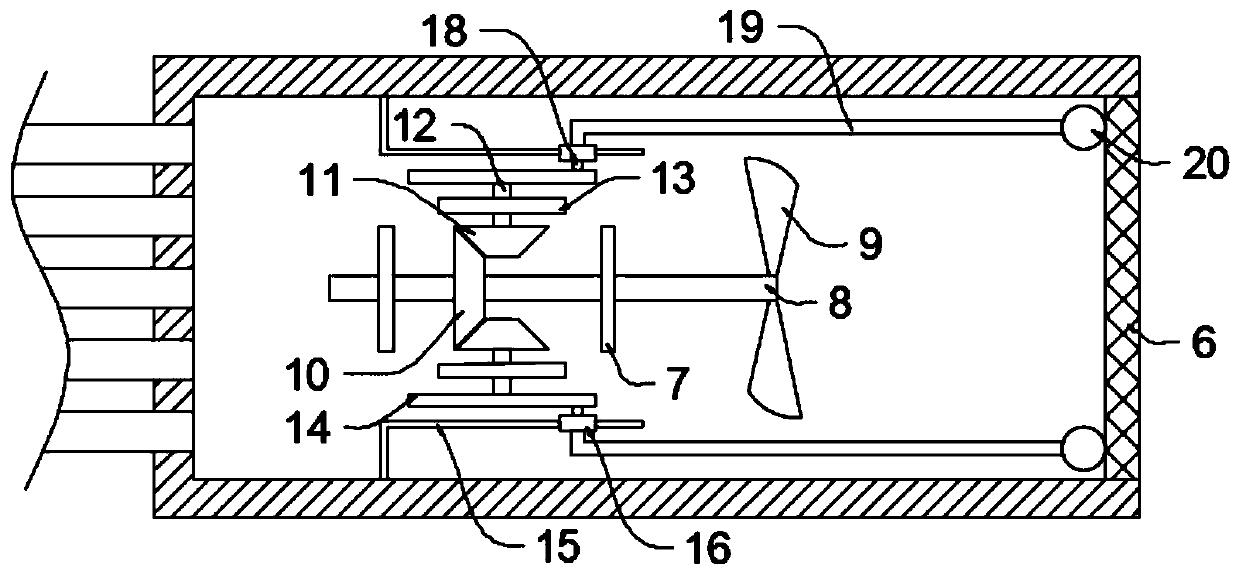

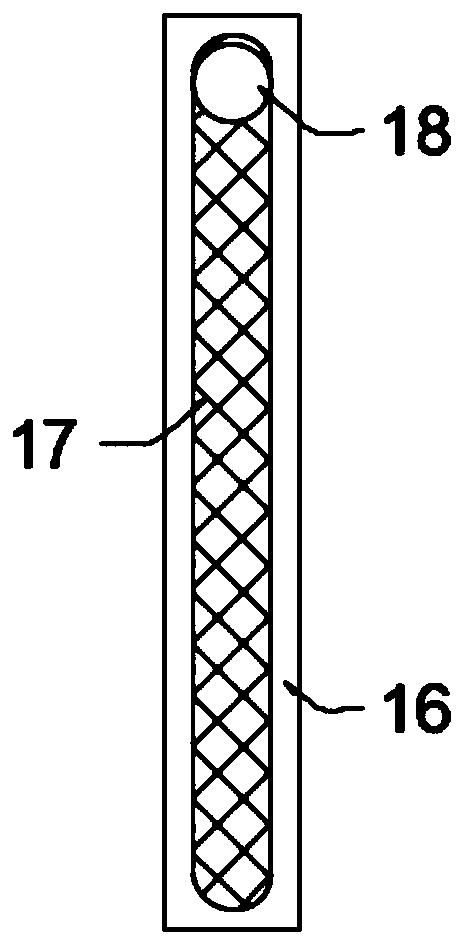

[0015] refer to Figure 1-3 , an energy-saving boiler that can quickly reduce dust, including a boiler body 1, a furnace 2 is arranged inside the boiler body 1, an air filter chamber 3 is connected to the upper end of the furnace 2, and the end of the filter chamber 3 far away from the furnace 2 is connected to the A gas pipe 4, the end of each gas pipe 4 away from the air filter chamber 3 is connected with a discharge pipe 5, and the discharge pipe 5 runs through the boiler body 1 and communicates with the outside world; The contact area is larger and the heat utilization rate is higher; a filter screen 6 is provided at the connection between the air filter chamber 3 and the furnace 2, and two first brackets 7 are fixed on the inner wall of the air filter chamber 3, and the two first brackets 7 are fixed A first rotating shaft 8 is connected for common rotation, and an impeller 9 is fixedly sleeved at one end of the filter screen 6 close to the first rotating shaft 8, and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com