Continuous production equipment for polymerization degree controllable reaction and using method thereof

A technology of production equipment and degree of polymerization, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, chemical/physical processes, etc., can solve problems such as narrow molecular weight distribution, and avoid uneven polymerization degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

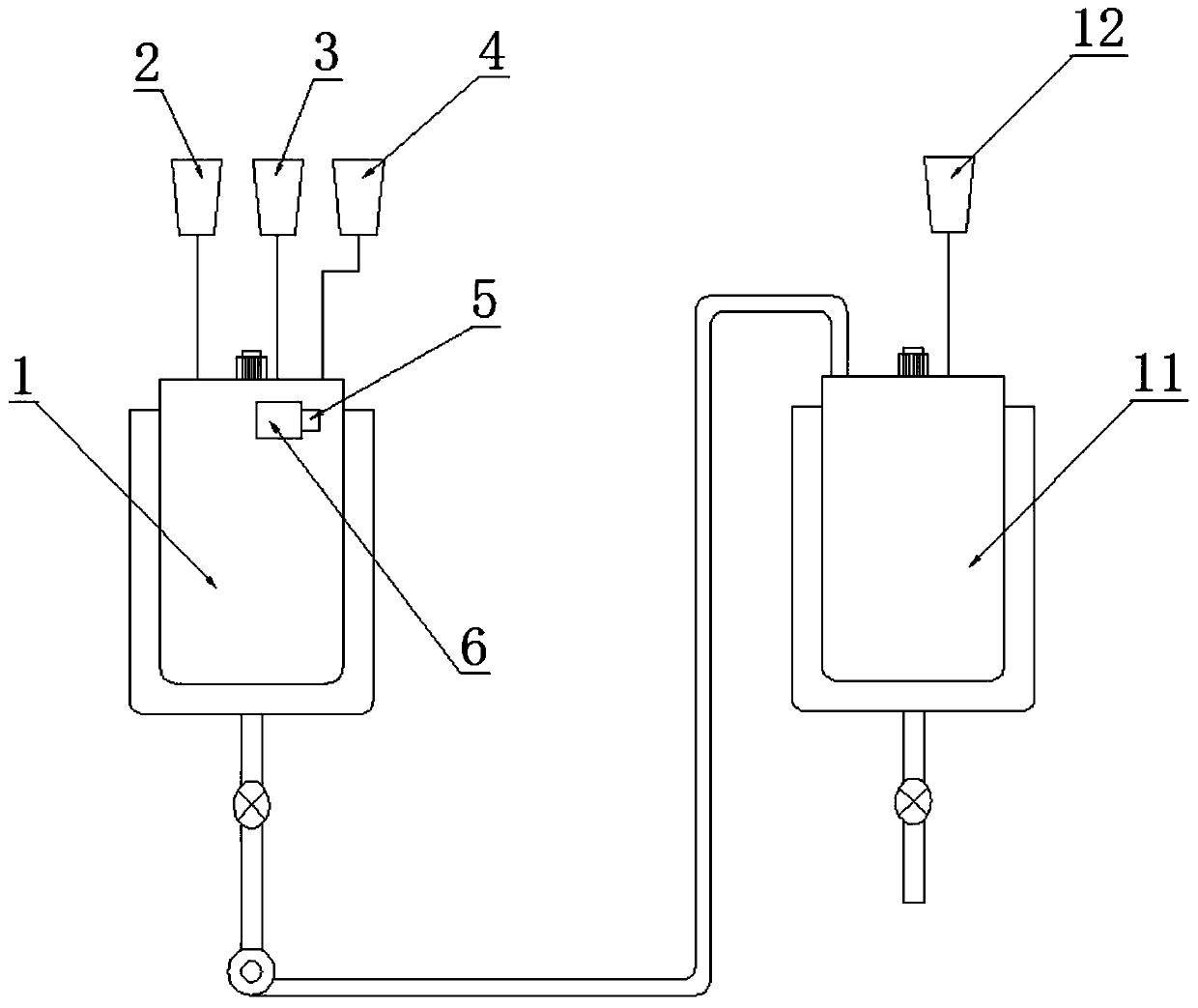

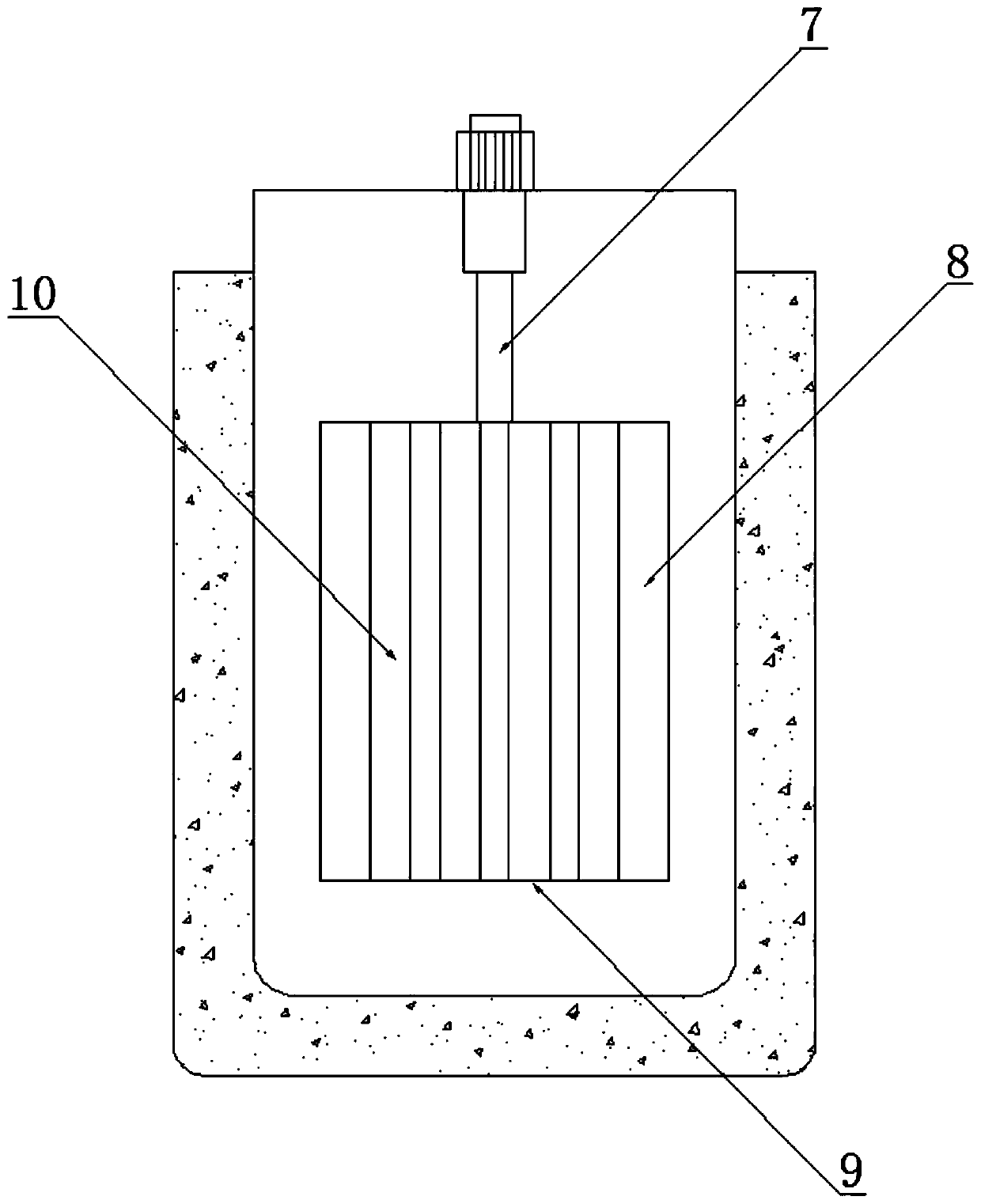

[0019] Such as Figure 1-3 As shown, a continuous production equipment for a reaction with a controllable degree of polymerization, including a photocatalytic reactor 1 and a composite stirring reactor 11, the top of the photocatalytic reactor 1 is connected with a monomer storage tank a2 and a monomer storage tank b3 With the photoinitiator tank 4, the top of the composite stirred reactor 11 is connected with a chain terminator storage tank 12, and the photocatalytic reactor 1 and the composite stirred reactor 11 tank bodies are all provided with circulating water insulation jackets, and the outlet of the photocatalytic reactor 1 The feed port is connected to the feed port of the composite stirring reactor 11 through a pressure pump; the upper part of the side wall of the photocatalytic reactor 1 is provided with a glass transparent plate 5, and the outer side of the glass transparent plate 5 is provided with a baffle 6, and the photocatalytic reactor 1 A cage stirrer is prov...

Embodiment 2

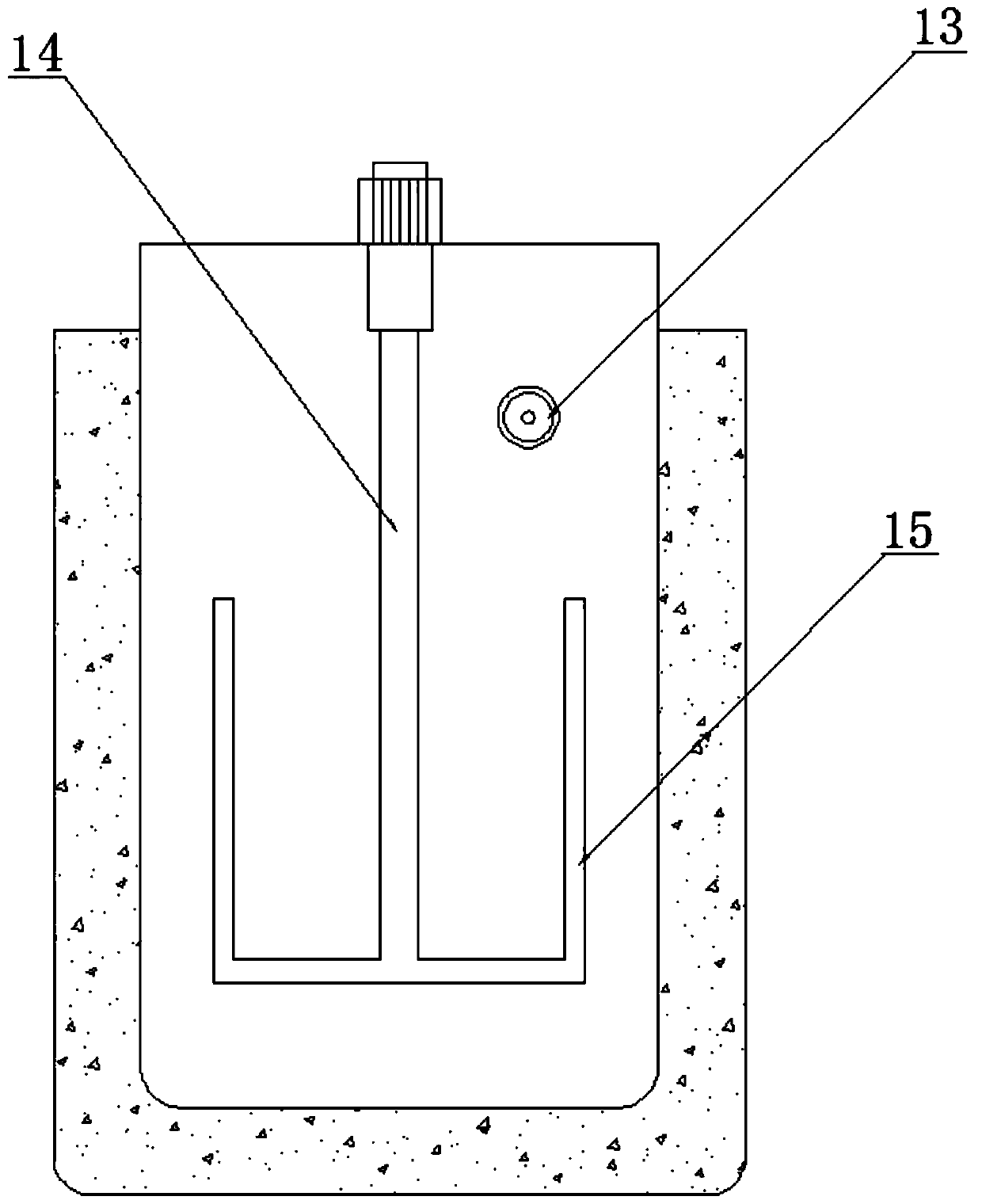

[0021] Such as Figure 1-4 As shown, a continuous production equipment for a reaction with a controllable degree of polymerization, including a photocatalytic reactor 1 and a composite stirring reactor 11, the top of the photocatalytic reactor 1 is connected with a monomer storage tank a2 and a monomer storage tank b3 With the photoinitiator tank 4, the top of the composite stirred reactor 11 is connected with a chain terminator storage tank 12, and the photocatalytic reactor 1 and the composite stirred reactor 11 tank bodies are all provided with circulating water insulation jackets, and the outlet of the photocatalytic reactor 1 The feed port is connected to the feed port of the composite stirring reactor 11 through a pressure pump; the upper part of the side wall of the photocatalytic reactor 1 is provided with a glass transparent plate 5, and the outer side of the glass transparent plate 5 is provided with a baffle 6, and the photocatalytic reactor 1 A cage stirrer is prov...

Embodiment 3

[0023] Such as Figure 1-3 with Figure 5 As shown, a continuous production equipment for a reaction with a controllable degree of polymerization, including a photocatalytic reactor 1 and a composite stirring reactor 11, the top of the photocatalytic reactor 1 is connected with a monomer storage tank a2 and a monomer storage tank b3 With the photoinitiator tank 4, the top of the composite stirred reactor 11 is connected with a chain terminator storage tank 12, and the photocatalytic reactor 1 and the composite stirred reactor 11 tank bodies are all provided with circulating water insulation jackets, and the outlet of the photocatalytic reactor 1 The feed port is connected to the feed port of the composite stirring reactor 11 through a pressure pump; the upper part of the side wall of the photocatalytic reactor 1 is provided with a glass transparent plate 5, and the outer side of the glass transparent plate 5 is provided with a baffle 6, and the photocatalytic reactor 1 A cage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com