Water-soluble color stabilizer for color photographic paper and preparation method thereof

An organic solvent, independent technology, applied in the field of water-soluble color stabilizer for color photographic paper and its preparation, which can solve the problems of fading, discoloration, color photo fading and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

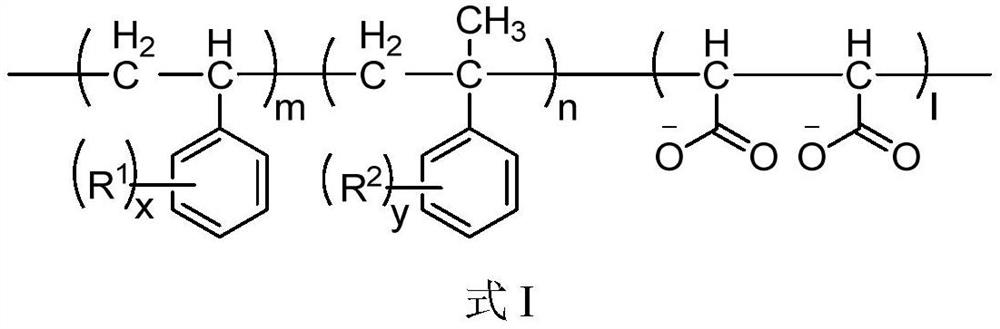

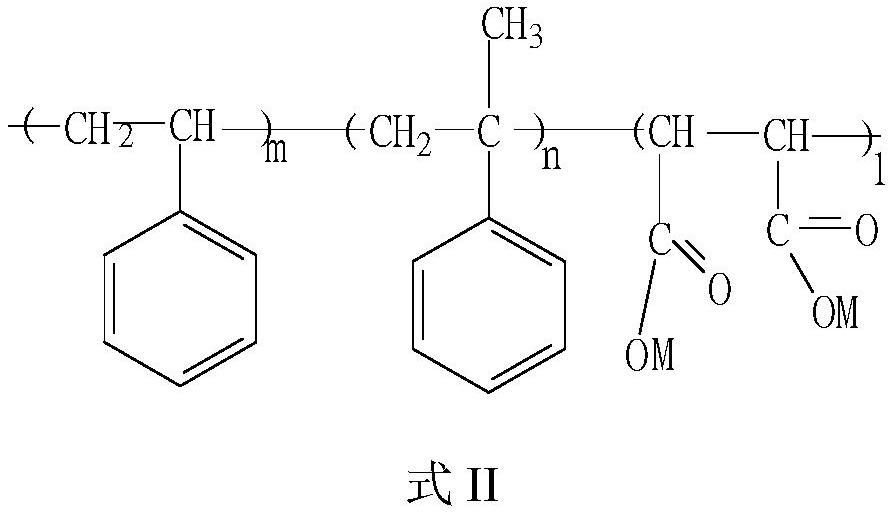

[0103] The invention discloses a preparation method of a water-soluble color stabilizer for color photographic paper, which comprises the following steps:

[0104] (1) Add a certain amount of solvent into the reaction vessel, and add a certain amount of maleic anhydride under stirring. After heating to 60°C-80°C, add the initiator. (2) After the temperature stabilized, start to drop the solution containing mixed monomers of styrene and α-methylstyrene. The dropping time is 1h-4h, and the temperature is controlled at 65°C-80°C; then keep it for 2h-8h. (3) After the reaction is completed, the solvent is distilled under reduced pressure. After the distillation is complete, add deionized water and an inorganic base, stir to dissolve and adjust the pH to 6-9. Filter to obtain a light yellow transparent liquid product. The method has simple synthesis process steps, is suitable for water-soluble colored paper emulsion, has good compatibility with the emulsion, is pollution-free, ...

Embodiment 1

[0135] In a 250mL flask, add 80.0mL of ethyl acetate, add 4.0g of maleic anhydride while stirring, heat in a water bath to 65°C, add 0.3g of benzoyl peroxide, when the temperature is stable at 65°C--70°C, start to drop A mixed monomer solution (2.3 mL of styrene, 15.6 mL of α-methylstyrene dissolved in 20.0 mL of ethyl acetate) was added. The dropping time is 2 hours, and the temperature is stable at 65°C--70°C. Then keep warm for 8 hours.

[0136] After that, ethyl acetate was distilled under reduced pressure and evaporated; 80.0 mL of deionized water and 25% ammonia water were added to adjust the pH to 6.5--7, stirred and dissolved, and filtered to obtain a color stabilizer, which weighed 105.5 g.

[0137] Product molecular weight: 3580; product appearance: light yellow transparent liquid; solid content 19.5%. Magenta dye image density drop rate from 85% to 10.5%.

Embodiment 2

[0139] In a 250mL flask, add 80.0mL of methyl ethyl ketone, add 4.0g of maleic anhydride while stirring, heat in a water bath to 65°C, add 0.3g of benzoyl peroxide, when the temperature is stable at 65°C--70°C, The dropwise addition of the mixed monomer solution (2.3 mL styrene, 15.6 mL α-methylstyrene dissolved in 20.0 mL methyl ethyl ketone) was started. The dropping time is 2 hours, and the temperature is stable at 65°C--70°C. Then keep warm for 8 hours.

[0140] Afterwards, methyl ethyl ketone was distilled under reduced pressure, and evaporated; 80.0 mL of deionized water and 25% ammonia water were added to adjust the pH=6.5--7, stirred and dissolved, and filtered to obtain a color stabilizer, weighing 105.5 g.

[0141] Product molecular weight: 3720; product appearance: light yellow transparent liquid; solid content 19.5%. The magenta dye image density drop rate was reduced from 85% to 10.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com