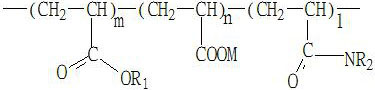

Water-soluble anti-fading agent for color photographic paper and preparation method thereof

An anti-fading, water-soluble technology, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of not using water-soluble color paper emulsion, easy to stick to the pot wall, difficult to clean, etc., to achieve a narrow range of molecular weight distribution, The degree of polymerization is easy to control and the synthesis process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] In a 250ml flask, 100.0ml of ethanol was added, and 6.0g of N-tert-butylacrylamide, 6.0g of butyl acrylate and 1.0g of acrylic acid were added with stirring. Heat the water bath to 65°C, add 0.7g of benzoyl peroxide, when the temperature is stable at 65°C--70°C, start to drop the mixed monomer solution (10.0g of N-tert-butylacrylamide, 10.0g of butyl acrylate and 1.5 g of acrylic acid dissolved in 35.0 ml of ethanol). The dropping time is 2 hours, and the temperature is stable at 65°C--70°C. Then keep warm for 6 hours.

[0085] After that, ethanol is distilled under reduced pressure, and the vacuum degree is maintained at 0.06-0.095Mpa. Evaporate; add 130.0ml of deionized water and 25% ammonia water to adjust PH=6.5--7, stir and dissolve, filter to obtain anti-fading agent, weighing 172.5g.

[0086] Product appearance: pale yellow transparent liquid; solid content 20%; fading rate of color photo paper is 9.5%.

Embodiment 2

[0088] In a 250ml flask, 85.0ml of ethanol was added, and 8.0g of N-tert-butylacrylamide, 4.0g of butyl acrylate and 4.0g of acrylic acid were added with stirring. Heat the water bath to 70°C, add 0.5g of benzoyl peroxide, when the temperature is stable at 70°C--75°C, start to drop the mixed monomer solution (8.0g N-tert-butylacrylamide, 4.0g butyl acrylate and 4.5 g of acrylic acid dissolved in 70.0 ml of ethanol). The dropping time is 2.5 hours, and the temperature is stable at 70°C--75°C. Afterwards, the reaction was incubated for 6.5 hours.

[0089] After that, ethanol is distilled under reduced pressure, and the vacuum degree is maintained at 0.06-0.095Mpa. Steamed; add 120ml of deionized water and 25% ammonia water to adjust the pH=7-7.5, stir and dissolve, filter to obtain the anti-fading agent, and weigh the total weight at 165g.

[0090] Product appearance: pale yellow transparent liquid; solid content 20%; fading rate of color photo paper 10.0%.

Embodiment 3

[0092] In a 250ml flask, 100.0ml of ethanol was added, and 6.0g of N-tert-butylacrylamide, 5.0g of ethyl acrylate and 1.0g of acrylic acid were added with stirring. Heat the water bath to 65°C, add 0.7g of benzoyl peroxide, when the temperature is stable at 65°C--70°C, start to drop the mixed monomer solution (10.0g of N-tert-butylacrylamide, 7.5g of butyl acrylate and 1.5 g of acrylic acid dissolved in 35.0 ml of ethanol). The dropping time is 2 hours, and the temperature is stable at 65°C--70°C. Then keep warm for 6 hours.

[0093] After that, ethanol is distilled under reduced pressure, and the vacuum degree is maintained at 0.06-0.095Mpa. Evaporate; add 120.0ml of deionized water and 25% ammonia water to adjust the pH=6.5-7, stir and dissolve, filter to obtain the anti-fading agent, and weigh the total weight at 155g.

[0094] Product appearance: pale yellow transparent liquid; solid content 20%; fading rate of color photo paper is 9.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com