A method for preparing cellulose with a low degree of polymerization by freezing and grinding, and its products and applications

A technology with a low degree of polymerization and cellulose, applied in the field of cellulose materials, to achieve the effects of excellent non-volatility of reagents, appropriate degree of polymerization, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

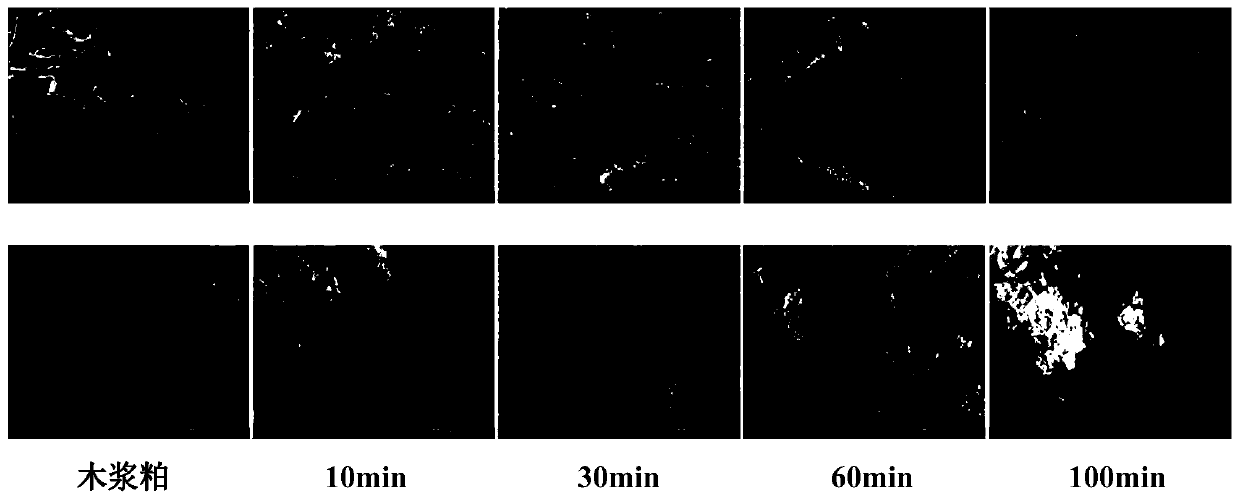

[0040] The cellulose raw material adopts wood pulp with a polymerization degree of 1700. First, the wood pulp is shredded, frozen in liquid nitrogen for 10 minutes, and then grinded for 10 minutes, 30 minutes, 60 minutes and 100 minutes respectively with a firing pin grinder. Liquid nitrogen maintains a low temperature environment. The degree of polymerization of the sample after grinding was tested using the national standard GB5888-86.

[0041] From figure 1 and figure 2 It can be seen that after grinding for 10 minutes, a white powder sample was obtained, with a yield of 99%, a degree of polymerization of 1399, and a particle size of 20-100 μm; after grinding for 30 minutes, a white powder sample was obtained, with a yield of 96%, a degree of polymerization of 970, and a particle size of 5-20 μm; after grinding for 60 minutes Finally, a white powder sample was obtained with a yield of 95%, a degree of polymerization of 540, and a particle size of 1-3 μm; after grinding f...

Embodiment 2

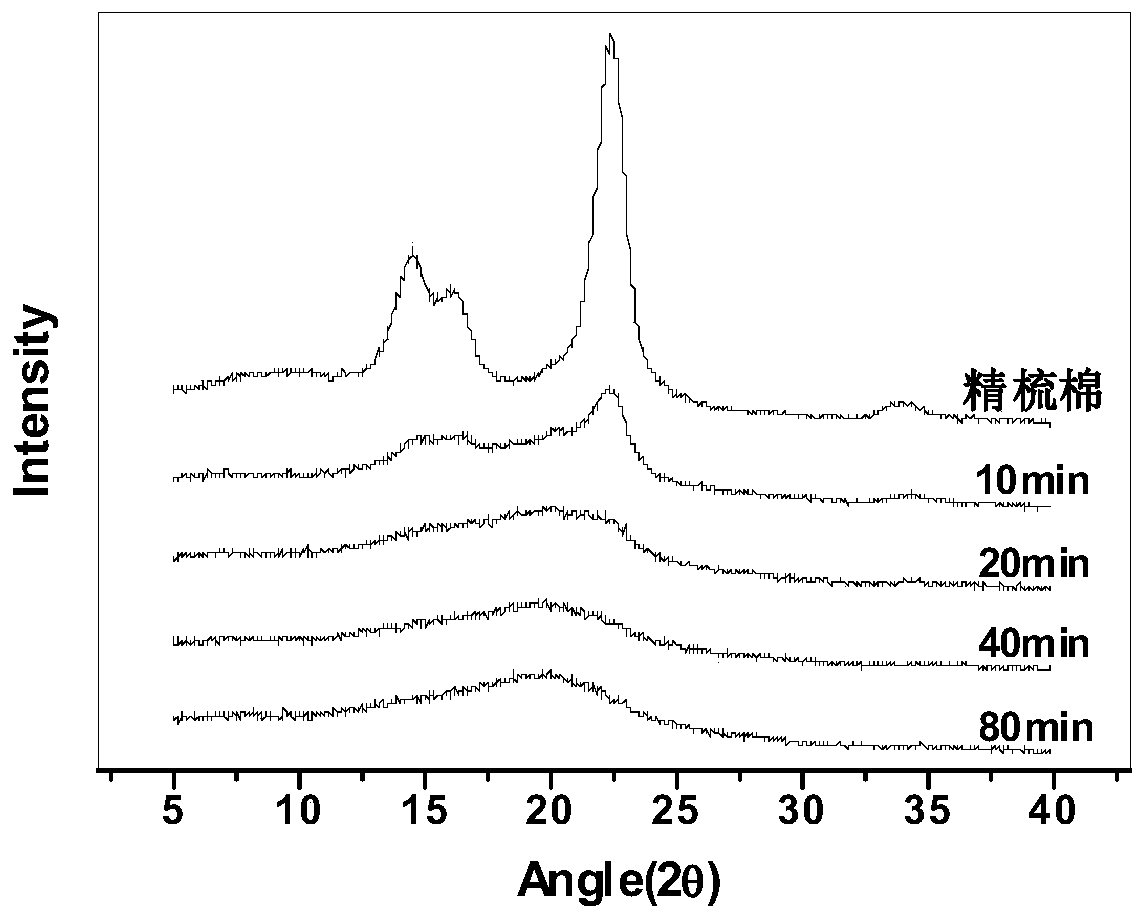

[0043] The cellulose raw material adopts white cotton fibrous combed cotton with a degree of polymerization of 4000. First, the combed cotton is frozen in dry ice for 30 minutes, and then the needle grinder is used to grind for 10 minutes, 20 minutes, 40 minutes and 80 minutes respectively. Dry ice maintains a low temperature environment. The degree of polymerization of the sample after grinding was tested using the national standard GB5888-86.

[0044] After grinding for 10 minutes, a white powder sample was obtained, with a yield of 99%, and a degree of polymerization of 3120; after grinding for 20 minutes, a white powder sample was obtained, with a yield of 98%, and a degree of polymerization of 2690; after grinding for 40 minutes, a white powder sample was obtained, with a yield of 96%, and a degree of polymerization of 1910 , the degree of crystallinity is close to 0; a white powder sample was obtained after grinding for 80 min, with a yield of 94% and a degree of polymer...

Embodiment 3

[0046] The cellulose raw material is microcrystalline cellulose with a degree of polymerization of 220 in white powder form. First, freeze the microcrystalline cellulose in liquid helium for 10 minutes, and then use a ball mill to grind it for 10 minutes, 20 minutes, 40 minutes, 60 minutes, 80 minutes, 100 minutes, and 120 minutes. , 150min and 180min, using liquid helium to maintain a low temperature environment during the grinding process. The degree of polymerization of the sample after grinding is tested using the national standard GB5888-86, and the degree of polymerization exceeds the test range by increasing the concentration of the sample solution to be tested.

[0047] After grinding for 10 minutes, a white powder sample was obtained, with a yield of 99%, and a degree of polymerization of 200; after grinding for 20 minutes, a white powder sample was obtained, with a yield of 98%, and a degree of polymerization of 181; after grinding for 40 minutes, a white powder sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com