A kind of preparation method of amino-terminated polyether

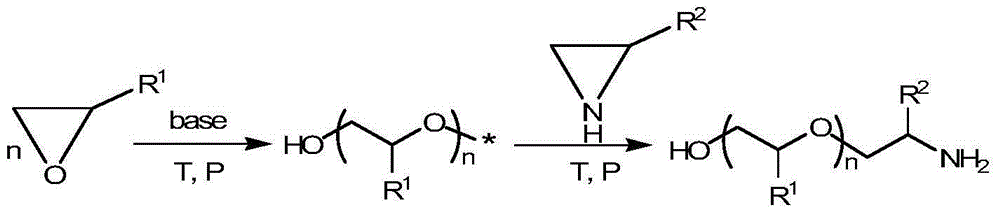

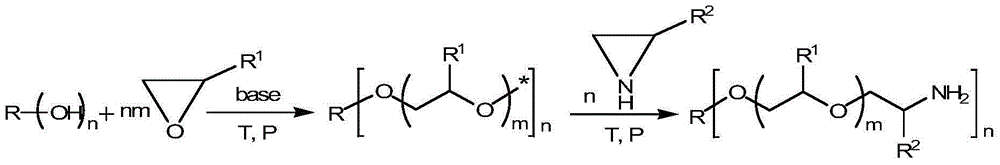

A technology of amino-terminated polyether and amino polyether, which is applied in the field of preparation of large-molecular-weight polyether, can solve the problems of high preparation cost, harsh preparation conditions, ammonia and hydrogen pollution of the environment, and achieve low reaction temperature and pressure, polymerization The effect of controllable degree and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Synthesis of single-ended amino polyether products with a degree of polymerization of isopropyl oxirane of 20. Initiator NaOH (as a catalyst at the same time); cycloethylamine is an end-capping agent, and the amount used is the same as the number of moles of NaOH. Weigh 40.00Kg of NaOH and add it into the reaction kettle, and vacuumize to -0.1MPa. Then the temperature of the reaction kettle is raised to 80°C, and 1720.00Kg of isopropyl oxirane is passed into the reaction kettle within 1 hour, and the temperature of the reaction kettle is maintained between 80°C and 90°C and the pressure is between 1.5MPa and 2Mpa during the feeding process. , After the addition of isopropyl oxirane, keep the temperature at 80°C for about 1h. Until the pressure of the reactor no longer decreases, vacuumize to -0.1MPa, and then feed 43.00Kg of cycloethylamine into the reactor. When the pressure in the reactor no longer decreases, it means that the reaction has ended. Release the materia...

Embodiment 2

[0050] Synthesis of single-ended amino polyether products with a polymerization degree of butyl oxirane of 20. Initiator KOH (as a catalyst at the same time); Cycloethylamine is an end-capping agent, and the amount used is the same as the number of moles of KOH. Weigh 56.00Kg of KOH into the reaction kettle, and vacuumize to -0.1MPa. Then the temperature of the reaction kettle is raised to 120°C, and 2000.00Kg of butyl ethylene oxide is introduced into the reaction kettle within 0.5h. After the addition of ethane, keep the temperature at 120°C for about 5 hours. Until the pressure of the reactor no longer drops, vacuumize to -0.1MPa. Then feed cycloethylamine 43.00Kg in the reactor, and when the pressure in the reactor no longer decreased, the reaction had ended. Release the material in the reaction kettle, which is dark brown and has a strong ammonia smell, and the ammoniation rate of the aforementioned material is tested.

Embodiment 3

[0052] Synthesis of single-ended amino polyether products with a degree of polymerization of ethylene oxide of 40. Initiator sodium methoxide (as a catalyst at the same time); cycloethylamine is an end-capping agent, and the consumption is the same as the molar number of sodium methoxide. Weigh 54.00Kg of sodium methoxide into the reaction kettle, and vacuumize to -0.1MPa. Then the temperature of the reaction kettle is raised to 100°C, and 1760.00Kg of ethylene oxide is introduced into the reaction kettle within 3 hours. After the addition of ethane, keep the temperature at 100°C for about 1 hour. Until the pressure of the reactor no longer drops, vacuumize to -0.1MPa. Then feed cycloethylamine 43.00Kg in the reactor, and when the pressure in the reactor no longer decreased, the reaction had ended. Release the material in the reaction kettle, which is light brown and has a strong ammonia smell, and the ammoniation rate of the aforementioned material is tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com