Self-buckling type ring mold powder spraying device

A powder spraying and ring technology, which is applied in the direction of spraying devices, rings, clothing, etc., can solve the problems of uneven powder coating, inability to close the ring mold, low powder coating efficiency, etc., and achieve good effect and high powder spraying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

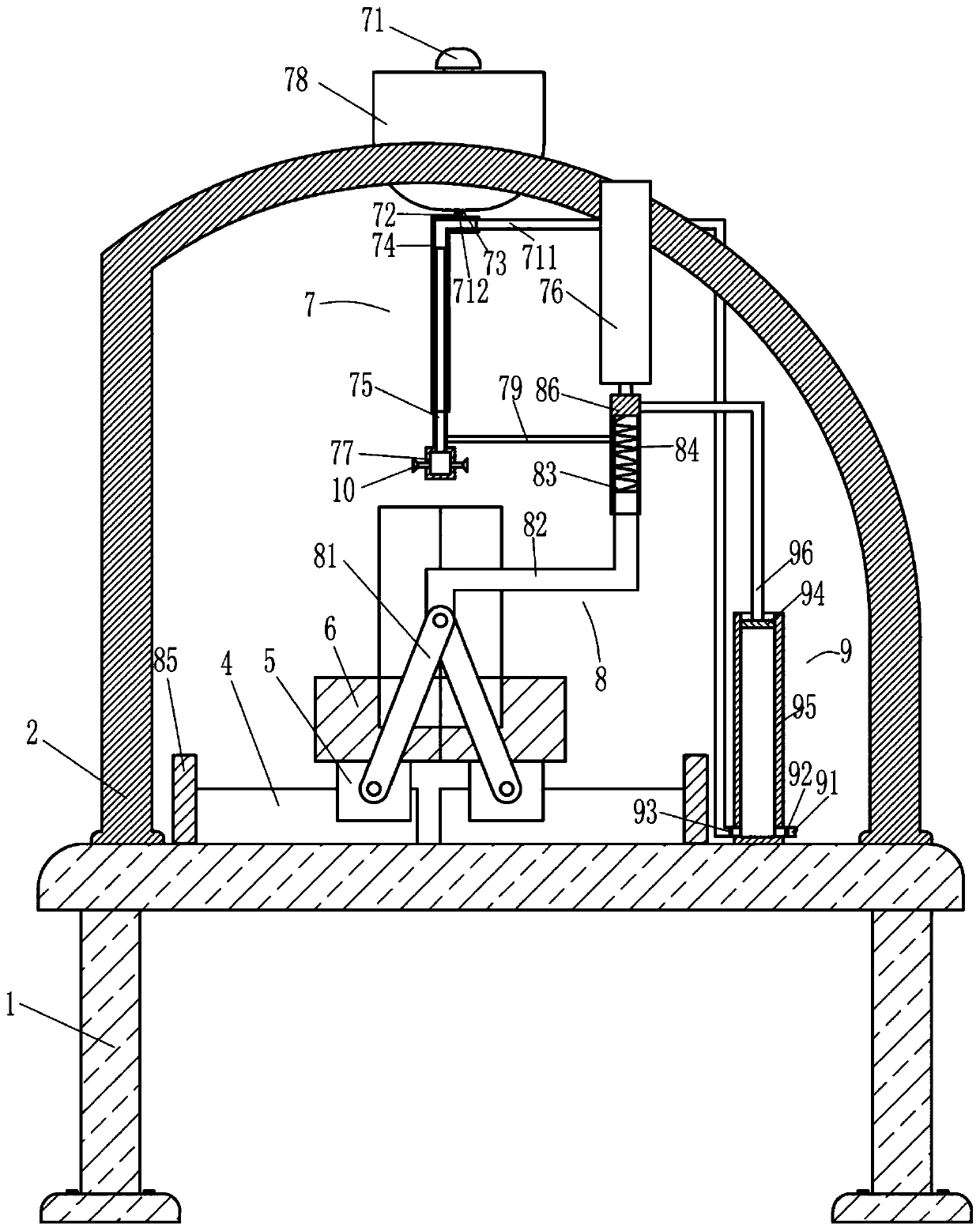

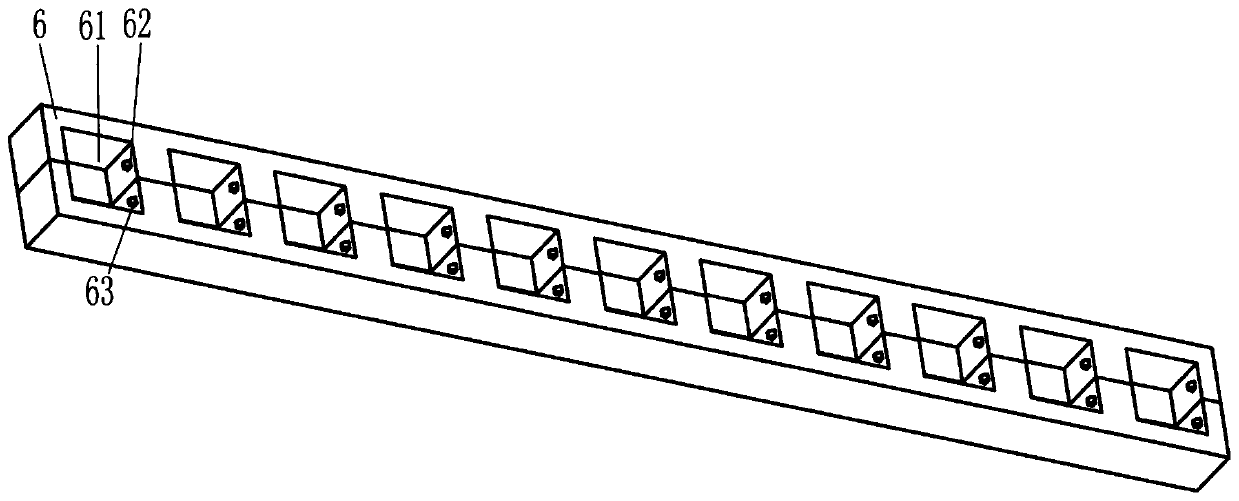

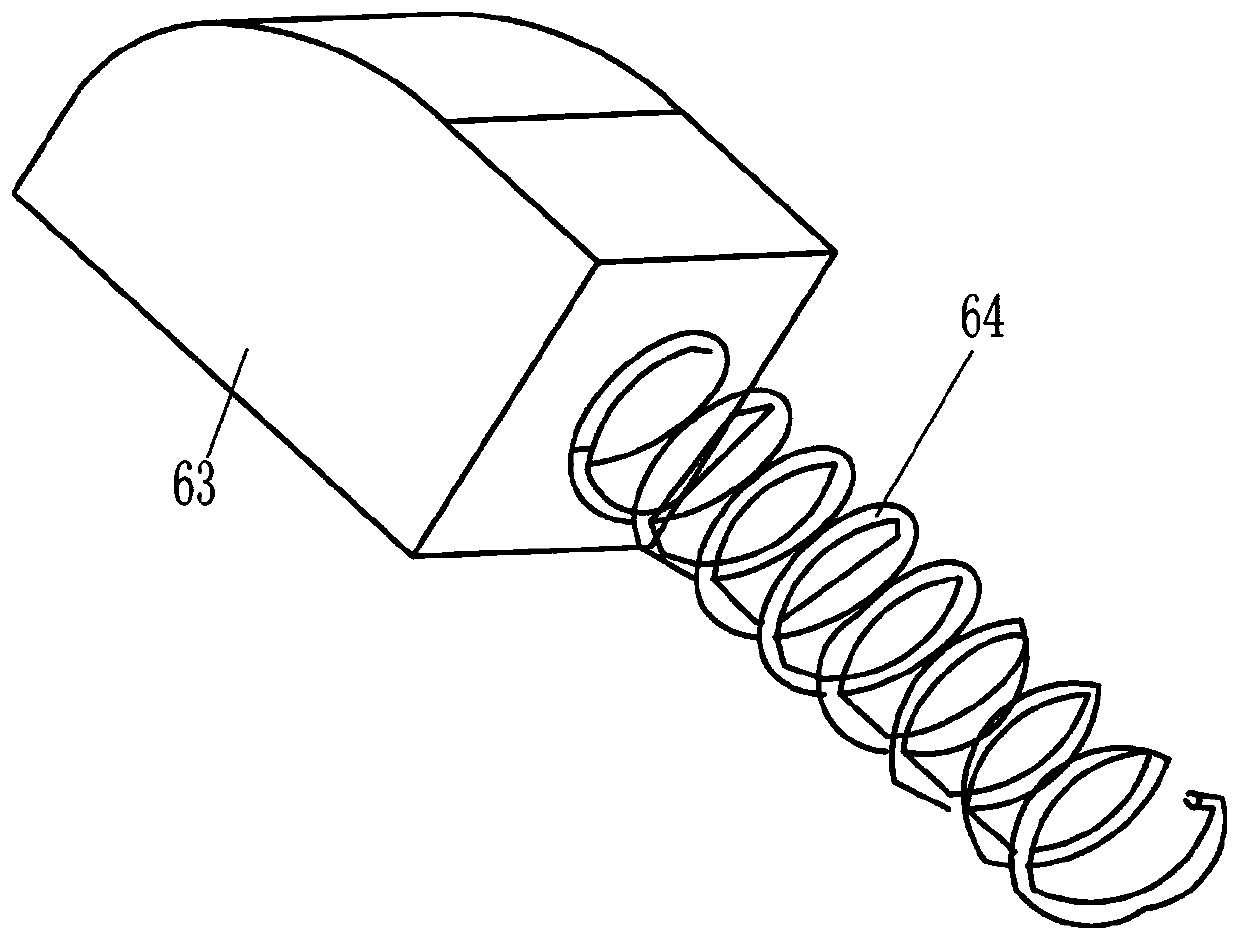

[0020] A self-fastening ring mold powder spraying device, such as Figure 1-4 As shown, it includes a frame 1, a mounting frame 2, a slide rail 4, a slider 5, a placement block 6, a powder spraying mechanism 7, a screw cap 71, a thin tube 72, an electric control valve 73, a fixed tube 74, and a powder storage Tank 78, connecting pipe 1 711, pushing mechanism 8 and blowing mechanism 9, the mounting frame 2 is fixedly installed on the upper side of the frame 1, and the mounting frame 2 is in the shape of an "arched door". Two slide rails 4 are fixedly installed on the upper side and are positioned at the inner side of the mounting bracket 2. The two slide rails 4 are slidably installed with a slide block 5 cooperating with it. The two slide blocks 5 can move left and right. The upper side part of block 5 is equipped with placing block 6, and all offer eleven placement grooves 61 for placing the ring mold that needs to carry out powder spraying operation on two described placing ...

Embodiment 2

[0023] A self-fastening ring mold powder spraying device, such as Figure 1-4 As shown, it includes a frame 1, a mounting frame 2, a slide rail 4, a slider 5, a placement block 6, a powder spraying mechanism 7, a screw cap 71, a thin tube 72, an electric control valve 73, a fixed tube 74, and a powder storage Tank 78, connecting pipe 1 711, pushing mechanism 8 and blowing mechanism 9, the mounting frame 2 is fixedly installed on the upper side of the frame 1, and the mounting frame 2 is in the shape of an "arched door". Two slide rails 4 are fixedly installed on the upper side and are positioned at the inner side of the mounting bracket 2. The two slide rails 4 are slidably installed with a slide block 5 cooperating with it. The two slide blocks 5 can move left and right. The upper side part of block 5 is equipped with placing block 6, and all offer eleven placement grooves 61 for placing the ring mold that needs to carry out powder spraying operation on two described placing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com