Device and method for manufacturing special-shaped steel through local heating and cold roll forming

A special-shaped steel, local heating technology, applied in the workpiece heating device, metal rolling, manufacturing tools and other directions, can solve the problem of uneven deformation of the workpiece, large size deviation, cracks and other problems, to achieve less equipment investment, small footprint , the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

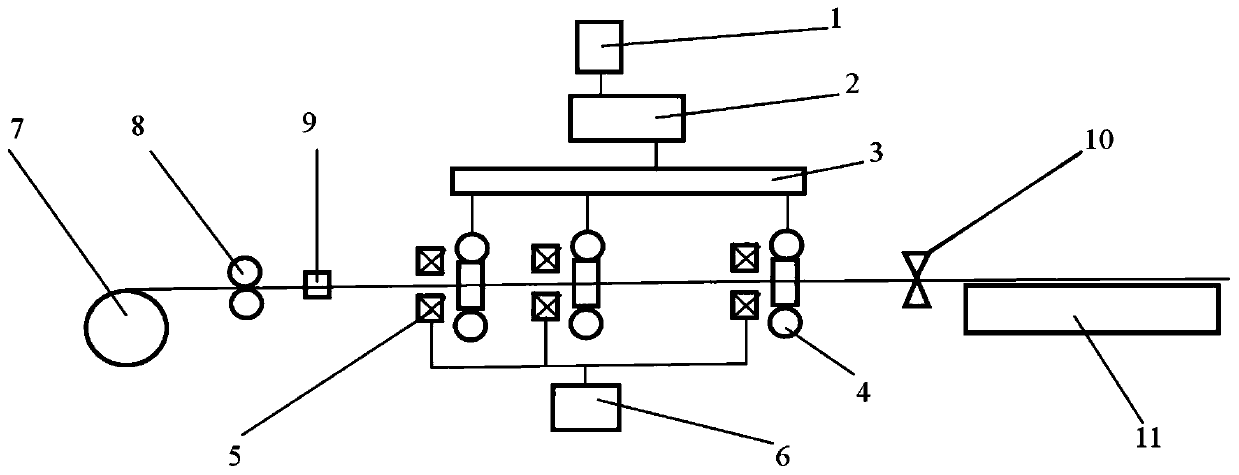

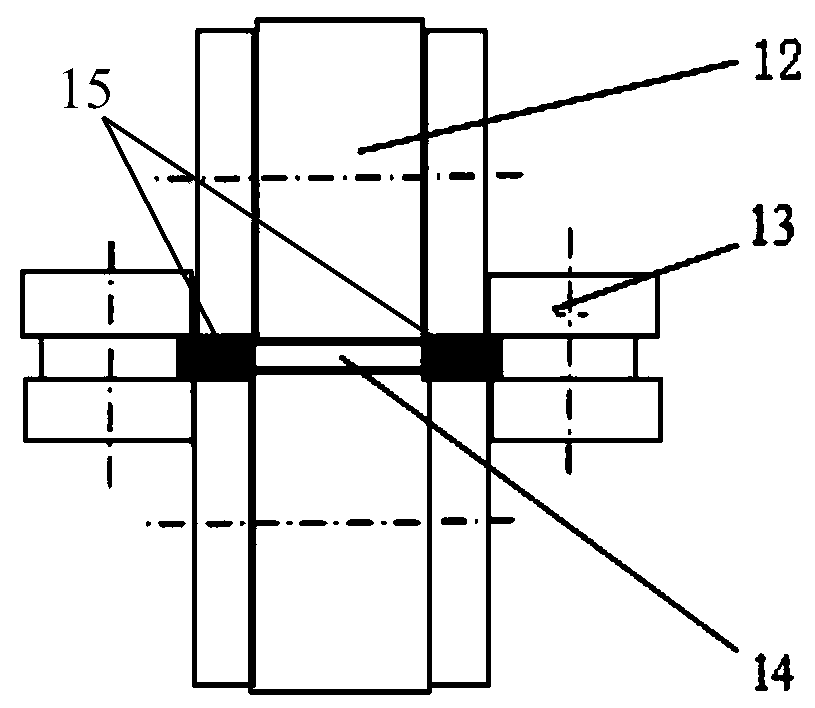

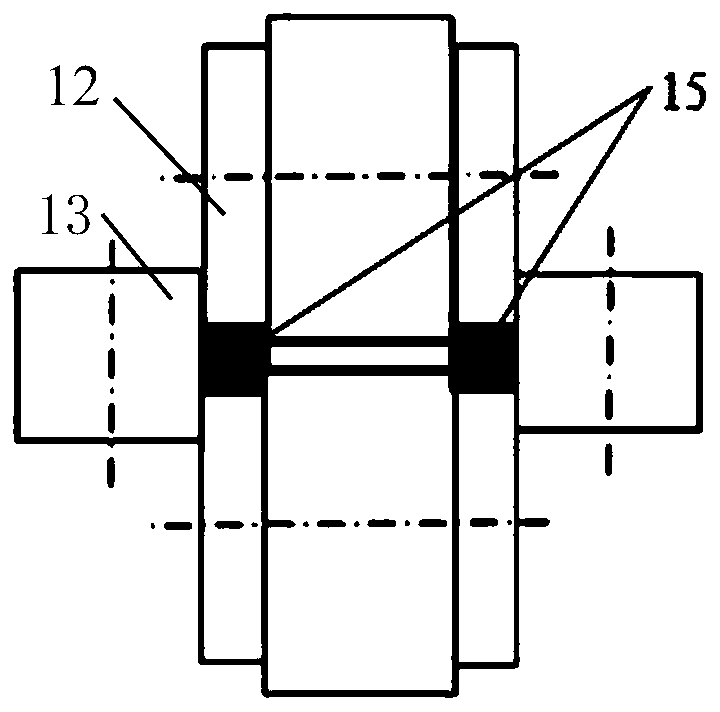

[0036] The multi-pass edge thickening and rolling forming device for induction heating plates completed by this invention has been implemented, and the specific form is as attached figure 1 As shown, it mainly includes an uncoiler 7, a leveler 8, a centering device 9, a shearing machine 10, a collection platform 11, a transmission motor 1 in the power transmission device, a reducer 2, and a transmission distribution box 3. It is characterized by It also includes 3 to 6 sets of induction heaters 5 and 3 to 6 forming frames 4, including uncoilers 7, levelers 8, centering devices 9, induction heaters 5, forming frames 4, shears 10, The collection table 11 is placed on a central line according to the above-mentioned order. According to the requirement, a group of induction heaters 5 is arranged in front of each forming frame 4, and each group of induction heaters includes 2 to 4 induction heating devices. The equipment is driven centrally and uniformly by the power unit, among whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com