Automatic assembling device for air deflectors

An automatic assembly device and air deflector technology, which is applied in packaging, transportation and packaging, and unsealing of objects, can solve problems such as low operating efficiency, many operating procedures, and high difficulty, so as to reduce oiling time and improve product quality. , the effect of precise assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

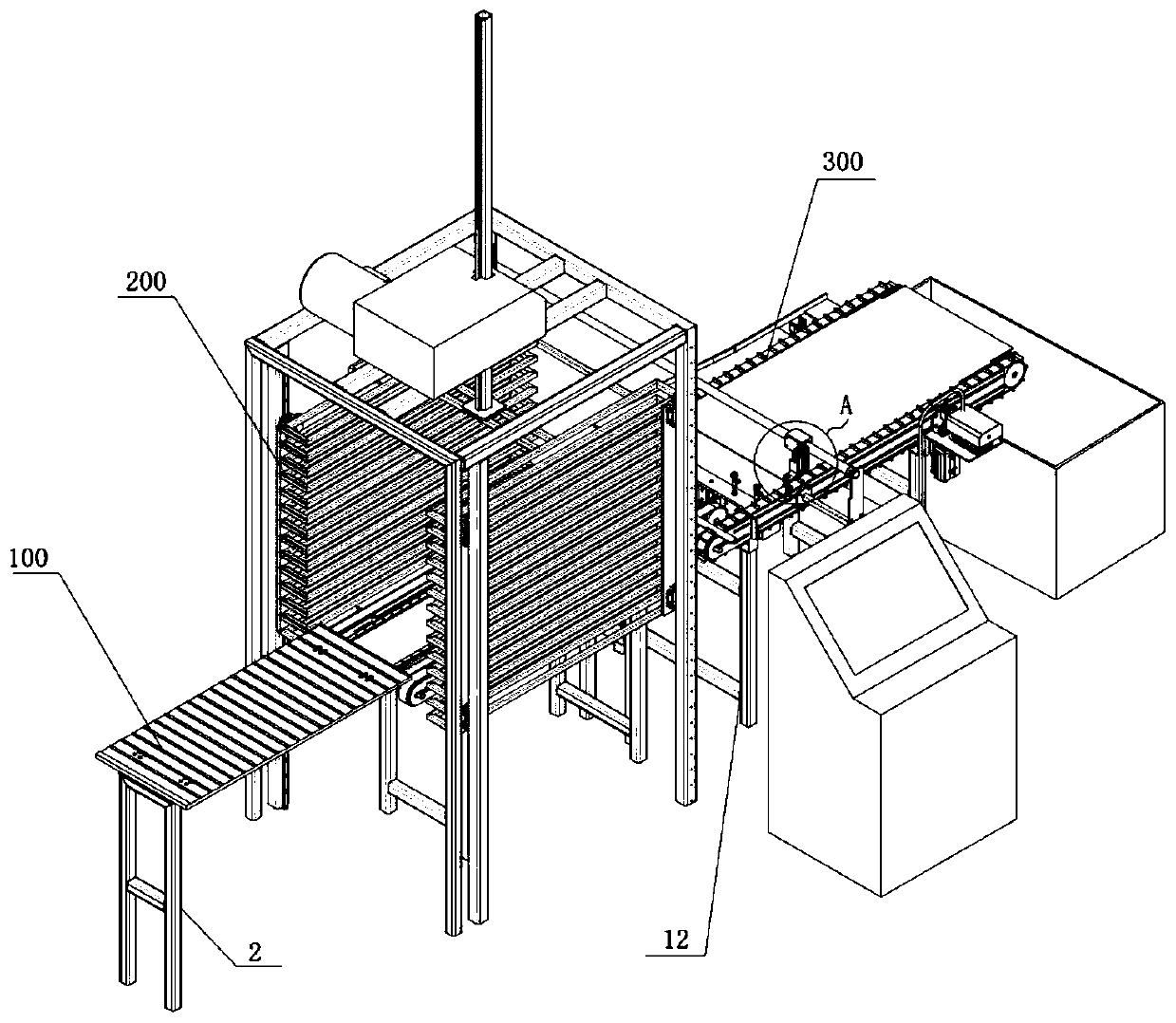

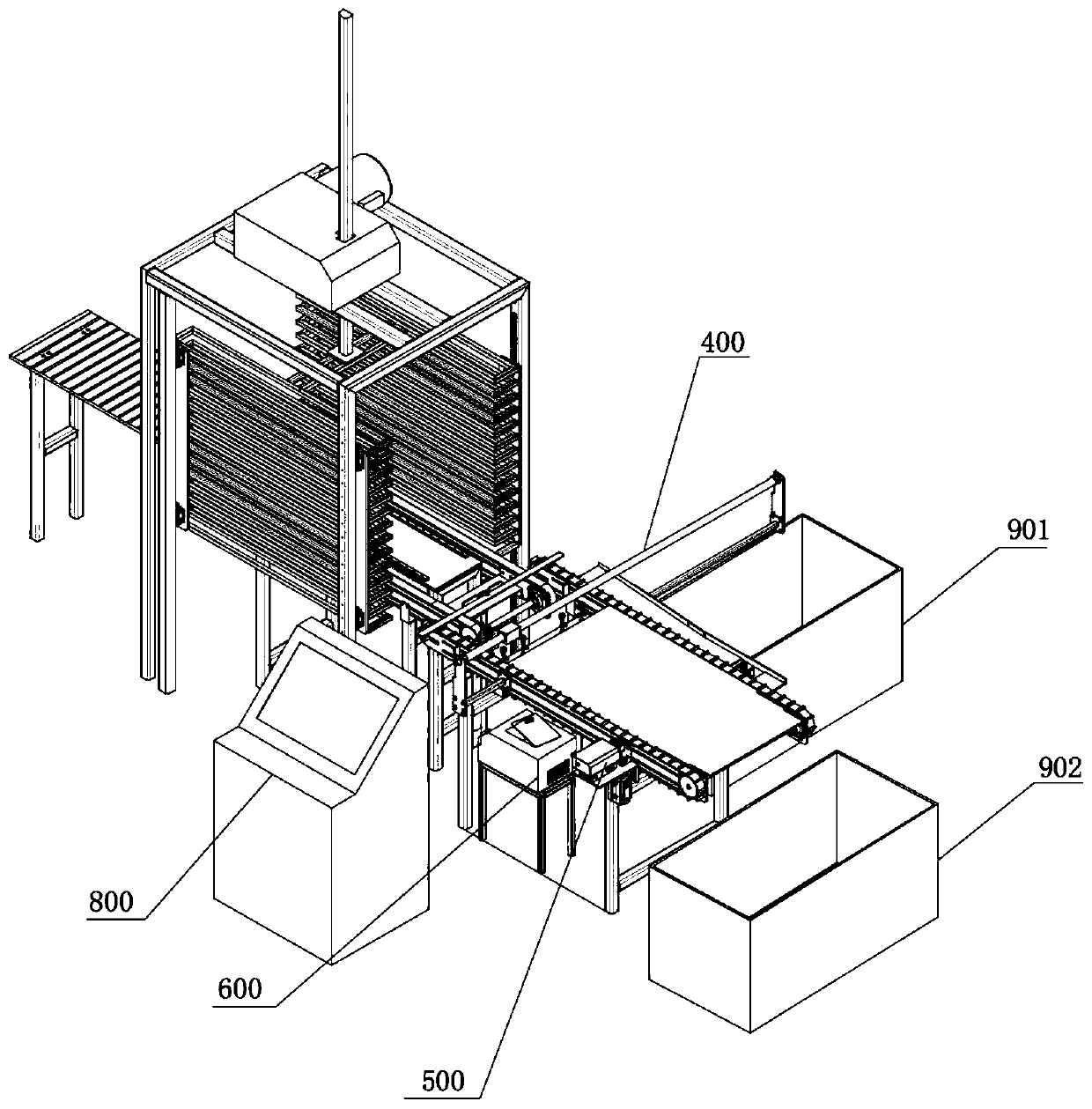

[0039] Such as figure 2 , image 3As shown, the automatic assembly device for the wind deflector provided in this embodiment mainly includes an automatic feeding mechanism 100, an automatic storage mechanism 200, an automatic sorting belt line mechanism 300, an automatic stripping mechanism 400 and an automatic assembly shaft sleeve mechanism 500. The automatic feeding mechanism 100 is installed on the most upstream of the automatic assembly device for the wind deflector, and it is used to transport the wind deflector 1 into the automatic storage mechanism 200; wind deflector 1, and convey the wind deflector 1 to the automatic sorting belt line mechanism 300; the automatic so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com