A surface grinding equipment for post-processing of high and low voltage power distribution cabinets

A power distribution cabinet, high and low voltage technology, which is applied in the field of surface grinding equipment for post-processing of high and low voltage power distribution cabinets, can solve the problems of manpower consumption and low efficiency, and achieve fast fixing speed, guaranteed efficiency and good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

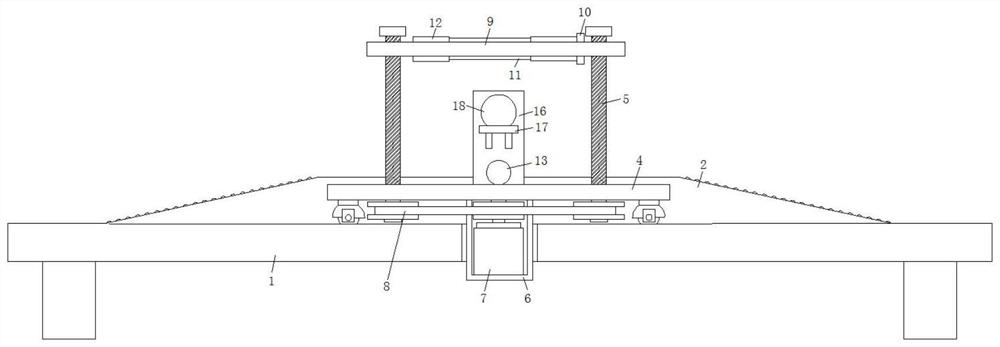

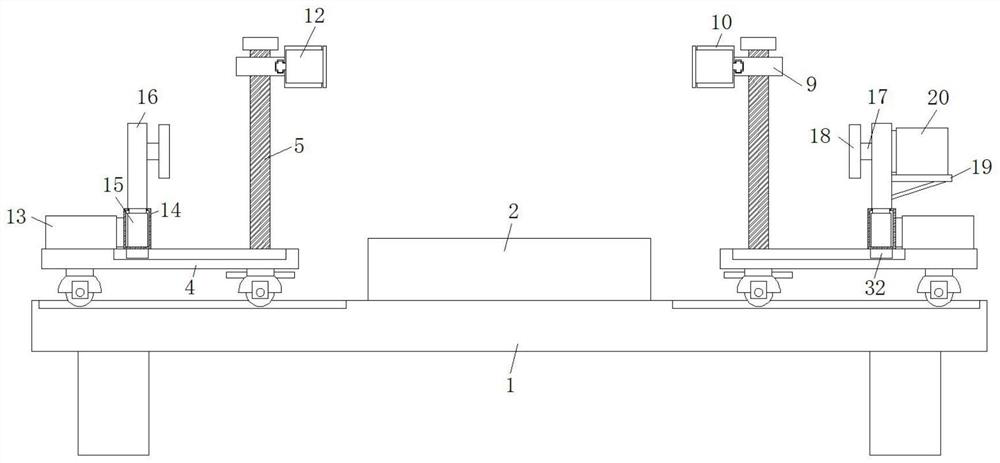

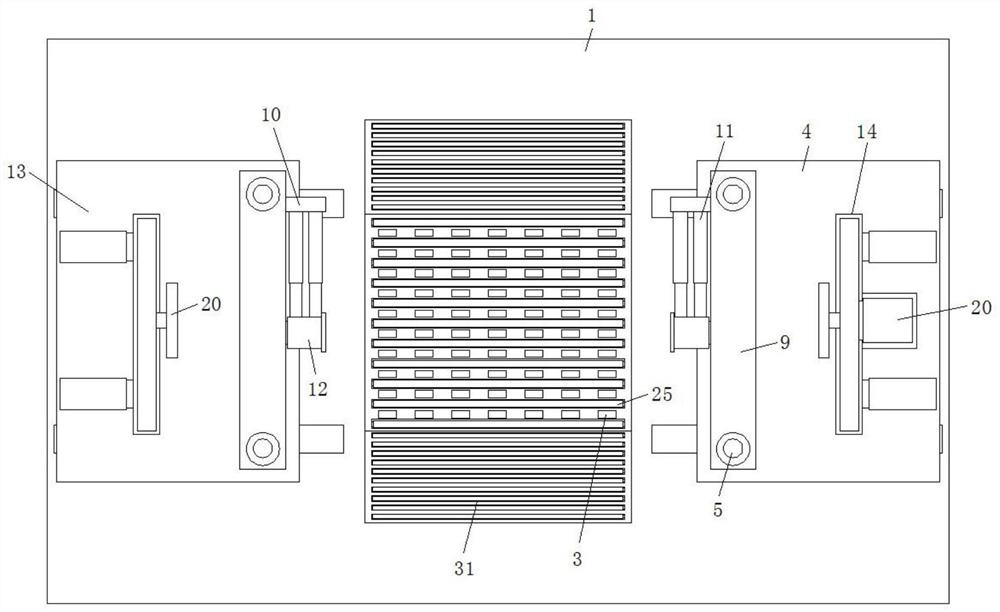

[0029] refer to Figure 1-4 , a surface grinding equipment for post-processing of high and low voltage power distribution cabinets, comprising a base 1, a grinding table 2 is fixedly connected to the middle of the top surface of the base 1, an electromagnetic block 3 is fixedly connected to the top surface of the grinding table 2, and the front and rear of the top surface of the base 1 Both sides are equipped with a grinding and turning mechanism, and the grinding and turning mechanism includes a mobile platform 4, and the mobile platform 4 is rollingly connected to the top surface of the base 1, and both sides of the top surface of the mobile platform 4 are rotatably connected with threaded rods 5. An installation cylinder 6 is fixedly connected, and the inner bottom surface of the installation cylinder 6 is fixedly connected with a servo motor 7 by screws. The lower ends of the two threaded rods 5 pass through the mobile platform 4 and the output end of the servo motor 1 7 is...

Embodiment 2

[0032] Such as figure 1 with 4 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, both sides of the grinding table 2 are inclined from top to bottom, and the end faces of both sides of the grinding table 2 are provided with rectangular grooves 30, and the front and rear sides of the rectangular grooves 30 The end inner wall is all rotatably connected with conveying roller two 31.

[0033] In this embodiment, a plurality of rectangular grooves 30 are provided on both sides of the grinding table 2, and the inner walls of the front and rear ends of the rectangular grooves 30 are rotatably connected with conveying rollers 2 31, thereby making loading and unloading of the power distribution cabinet more convenient. It provides a certain guarantee for the efficient production of power distribution cabinets.

Embodiment 3

[0035] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a chute is provided on the top surface of the mobile platform 4, and sliders 32 are fixedly connected to the bottom surface of the adjustment cylinder 14, and the sliders 32 are all slidably connected in the chute. .

[0036] In this embodiment, the adjustment cylinder 14 is slidably connected to the top of the moving platform 4 through a slider 32 and a chute, so that the adjustment cylinder 14 moves more smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com