Air spring energy storage passive type upper limb power assisting exoskeleton

A technology of gas springs and exoskeletons, applied in the field of exoskeletons, can solve problems such as tools falling out of hands, affecting work tasks and work efficiency, fatigue damage, etc., and achieve the effects of reducing load-carrying burden, avoiding safety accidents, and enhancing output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

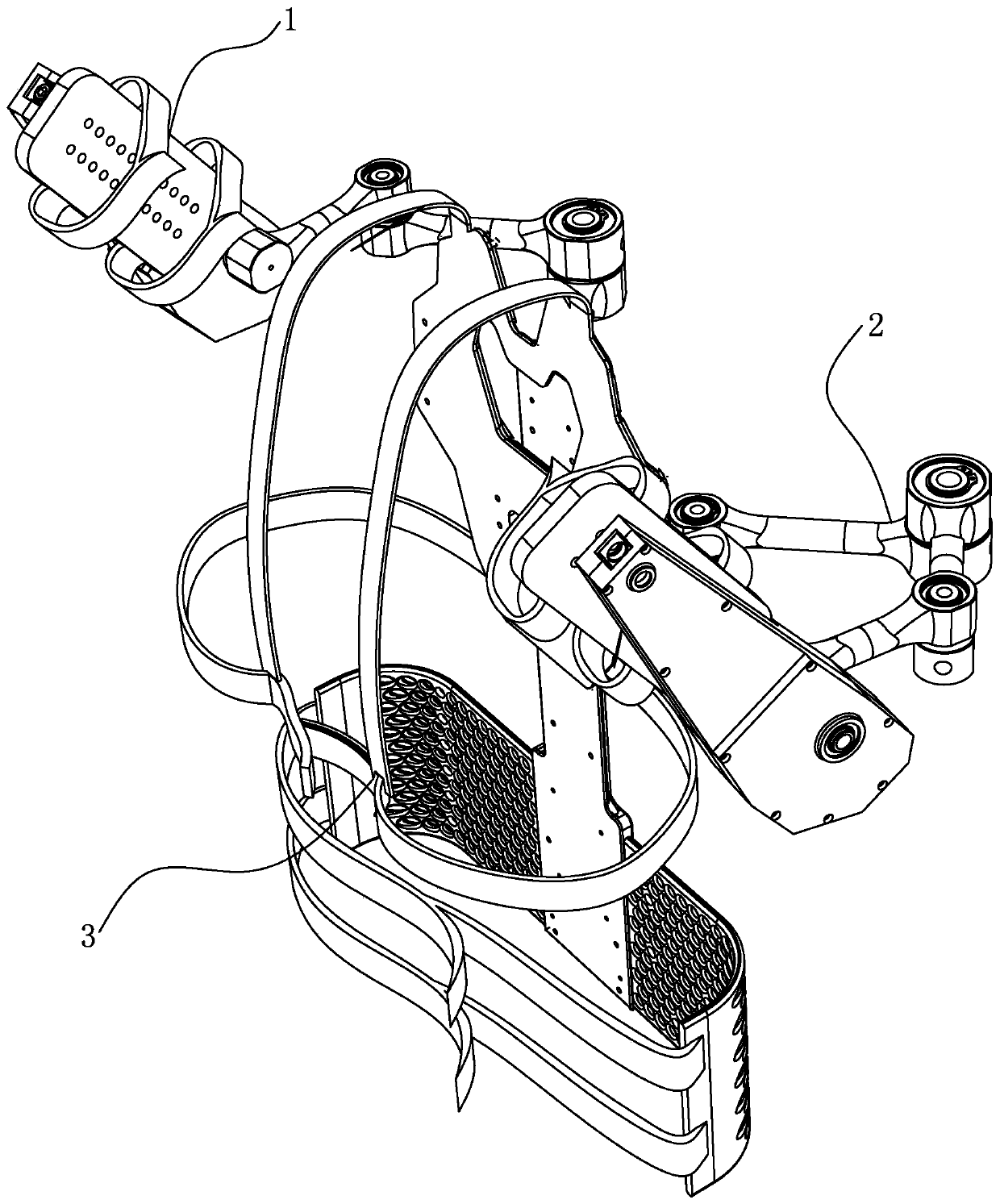

[0017] see Figure 1-Figure 3 As shown, a gas spring energy storage passive upper limb power-assisted exoskeleton in this embodiment includes a back bearing device 3, two shoulder motion mechanisms 2 and two arm power-assisted mechanisms 1;

[0018] A shoulder mechanism 2 and a big arm booster mechanism 1 are respectively arranged on both sides of the back carrying device 3;

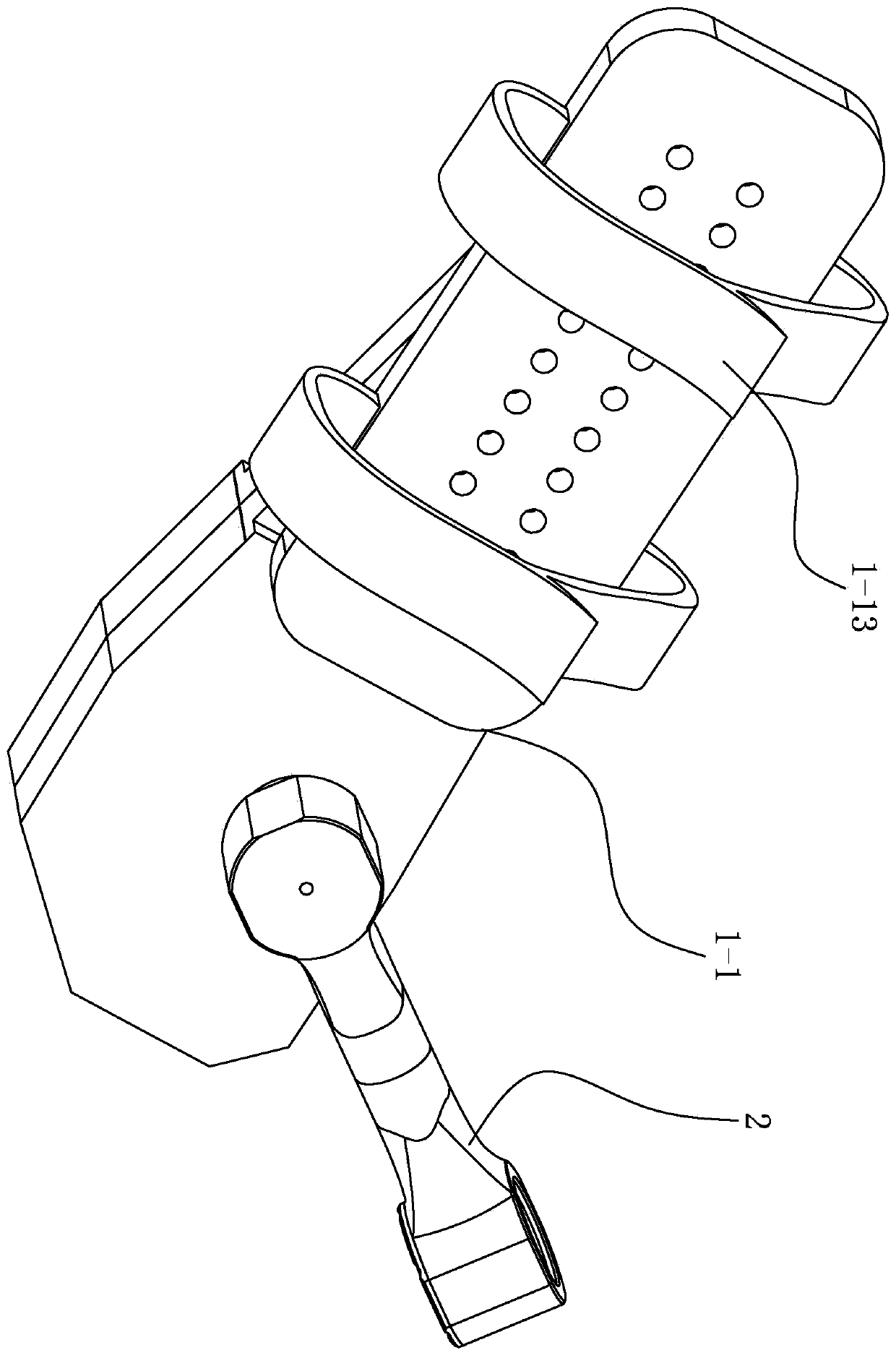

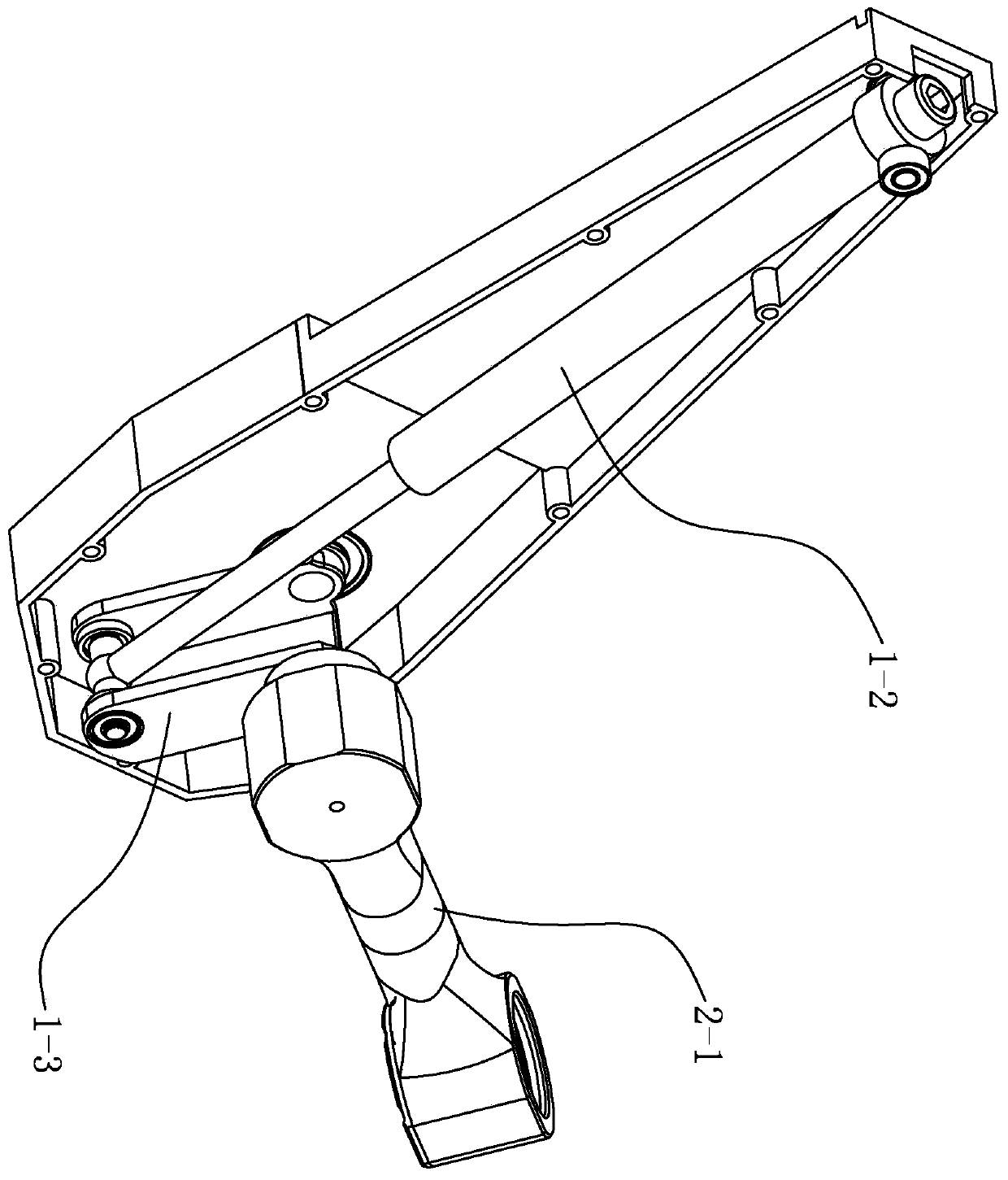

[0019] Each of the boom booster mechanisms 1 includes a boom tying 1-1, an elastic expansion member 1-2 and a shoulder connector 1-3; one end of the elastic expansion 1-2 is rotatably mounted on the boom tying 1- 1, the other end is rotatably installed on the shoulder connecting piece 1-3, the shoulder connecting piece 1-3 is fixedly connected with the shoulder movement mechanism 2, and the big arm binding 1-1 is rotatably set on the shoulder connecting piece 1 -3 up;

[0020] The rotation axis of the boom binding 1-1 is parallel to the rotation axes of both ends of the elastic telescopic member 1-2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com