Quick manufacturing method for safety certificate and safety certificate card

A production method and technology for ID cards, which are applied in the field of cards, can solve the problems of low service life, unsightly appearance, uneven edges of laminations, etc., and achieve the effects of fast production speed, fast production speed, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

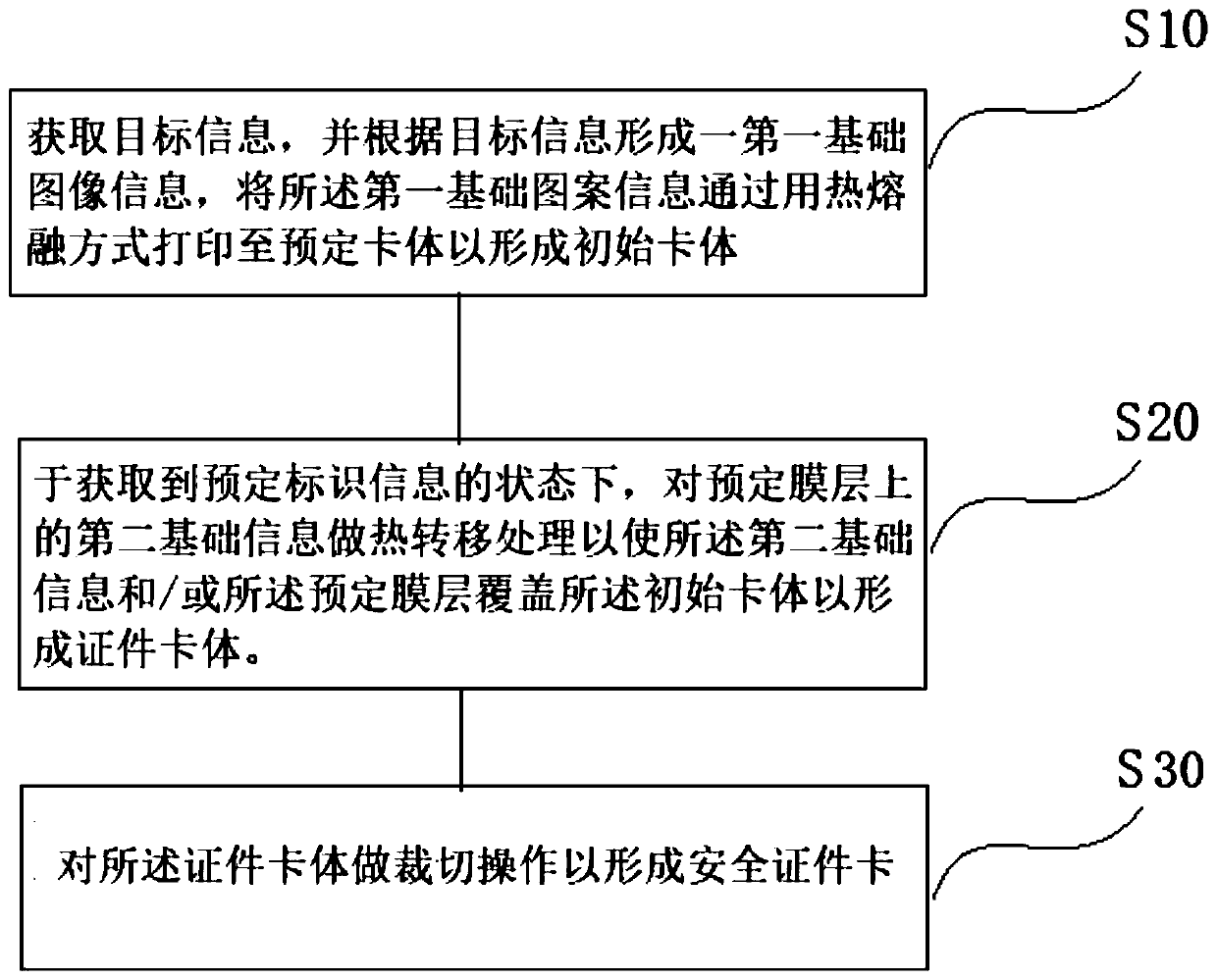

[0028] The present invention provides a method for quickly making a security certificate, which includes:

[0029] Step S10: Obtain target information, and form a first basic image information according to the target information, and print the first basic pattern information on a predetermined card body by thermal fusion to form an initial card body; wherein, the first basic image The image information contains at least basic personal information.

[0030] In this step, an implementation manner is listed as follows. In actual operation, first put a predetermined card body into the card feeder. The predetermined card body is an identifiable card base, which can be a chip card or It can be a chipless card. When the card body to be booked is in the printing state, the first basic pattern information is printed on the predetermined card body by thermal fusion to form an initial card body. The first basic image information may include personal identification information, photo informat...

Embodiment approach

[0032] In this step, one embodiment is listed as follows,

[0033] In actual operation, when the initial card body enters the film-coated state, the cursor information is read, and when the cursor information is obtained, the predetermined film layer is thermally transferred (hot stamped) to make the predetermined film layer The first basic information above covers the initial card body to form a document card body output. If the ID card body needs double-sided printing, put the surface of the card body without information recorded in the laminating state again, and repeat this step to achieve double-sided printing.

[0034] Step S30: Perform a cutting operation on the ID card body to form a security ID card, or punch the card body to form a cavity or chamfer.

[0035] As a further preferred embodiment, in the fast production method of a security certificate described above, the predetermined film layer records anti-counterfeiting information. For example, the predetermined film la...

Embodiment 2

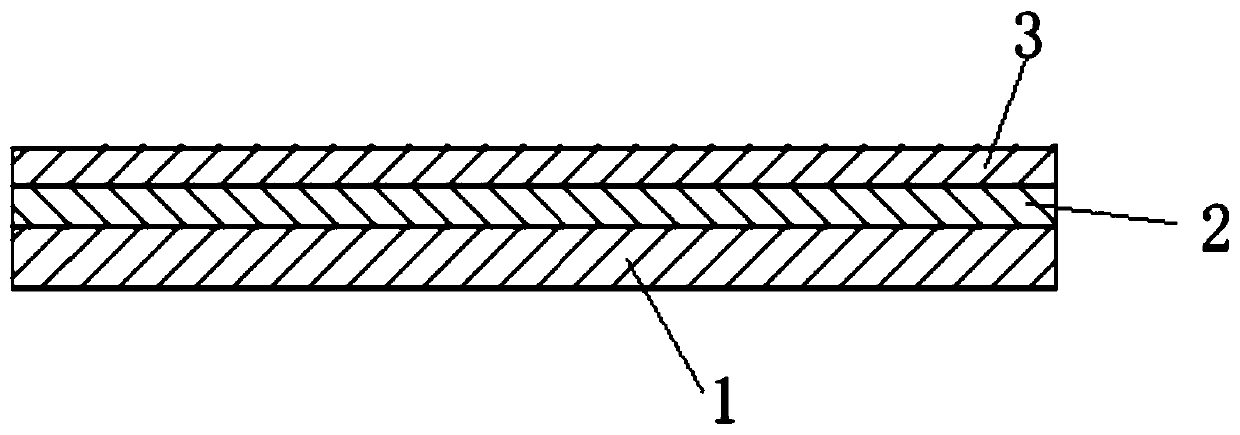

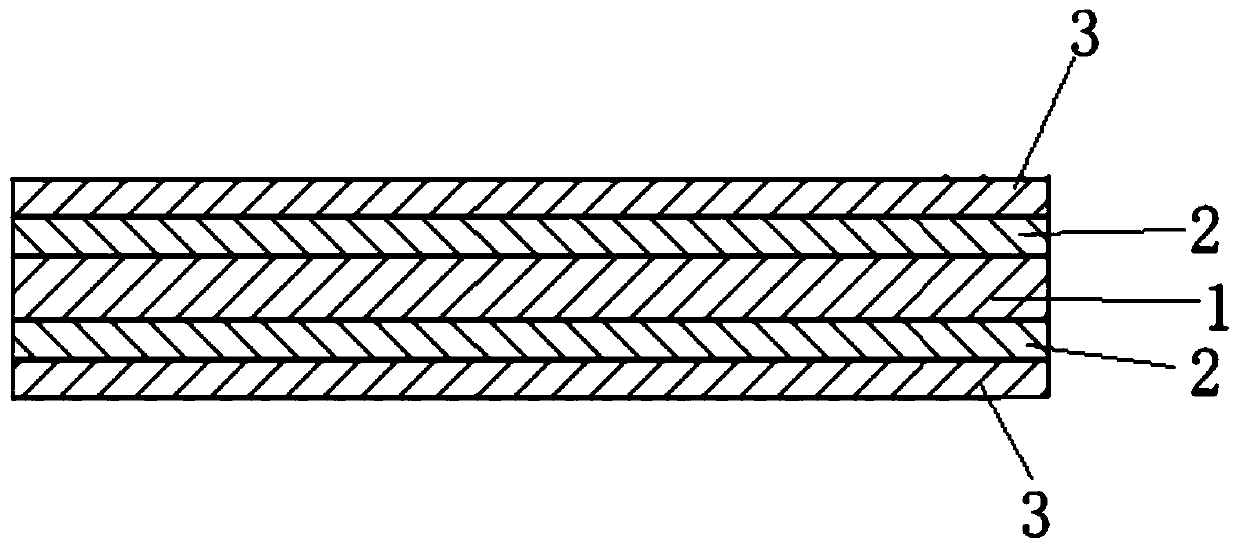

[0038] Such as figure 2 As shown, the present ID card includes a card body 1 with a card information layer 2 formed by thermal fusion printing, and a protective coating 3 on the card information layer 2 by hot stamping. The protective coating 3 is made of polyurethane resin or acrylic resin, and the protective coating 3 and the card information layer 2 are sequentially arranged from the outside to the inside. The card information layer 3 in the ID card is attached to the card body 1 by a hot-melt printer, and the protective coating 3 is provided to further isolate and protect the card information layer.

[0039] The thickness of the card body 1 is 0.8-1.2 μm, the thickness of the card information layer 2 is 0.1-0.5 μm, and the thickness of the protective coating 3 is 1.5-5 μm. The thickness of the ID card in this embodiment is relatively thin, light weight, and beneficial The production cost of the ID card is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com