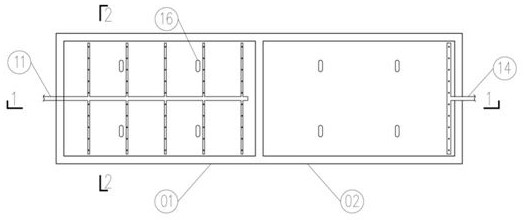

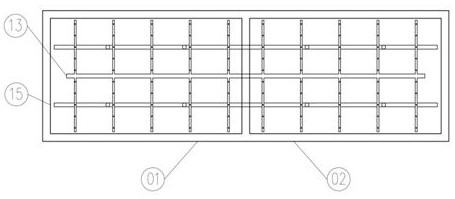

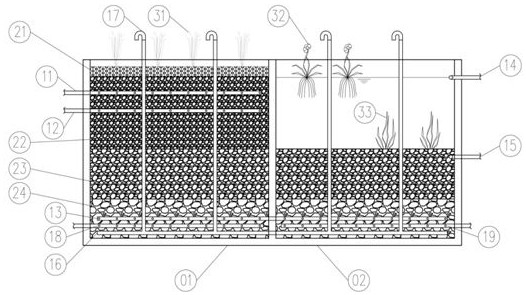

A composite constructed wetland with alternate operation subsurface flow and its application method

A technology of subsurface flow wetlands and operating methods, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of easy clogging, difficult overwintering, low treatment load, etc., and achieve the purpose of alleviating clogging , improve plant species, increase the effect of landscape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The wetland device of the present invention is used to treat the tail water of a municipal sewage treatment plant, and the COD removal rate, TN removal rate and filler blockage of the wetland device are observed. The dimensions of the two-level wetlands are both 1.0×1.0×1.0m, the effective depth is 0.8m, the treated water volume is 66L / h, and the nominal hydraulic retention time is 1d. During the continuous operation for 3 months from June 13 to September 13, 2019, the cycle time of the forward and reverse operation of the wetland device of the present invention is 7 days. The first month is the commissioning period, the second and third months are the operation period, and the COD and TN data of the last month are recorded every day. On September 14, the water level of the device is raised to 0.9m, all the aeration devices are turned on, and the records are recorded. Number of outlet points for two-stage wetlands.

[0035] Table 1 Weekly average value of COD in and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com