A kind of preparation method of waste grape fruit enzyme for fertilizer, prepared grape waste fruit enzyme and application thereof

A fruit enzyme and grape technology, applied in the preparation and application of organic fertilizers, liquid fertilizers, etc., can solve the problems of incomplete decomposition of effective components, unusable waste fruits, unsuitable promotion and use, etc., to improve the use value and facilitate promotion. The effect of using and shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

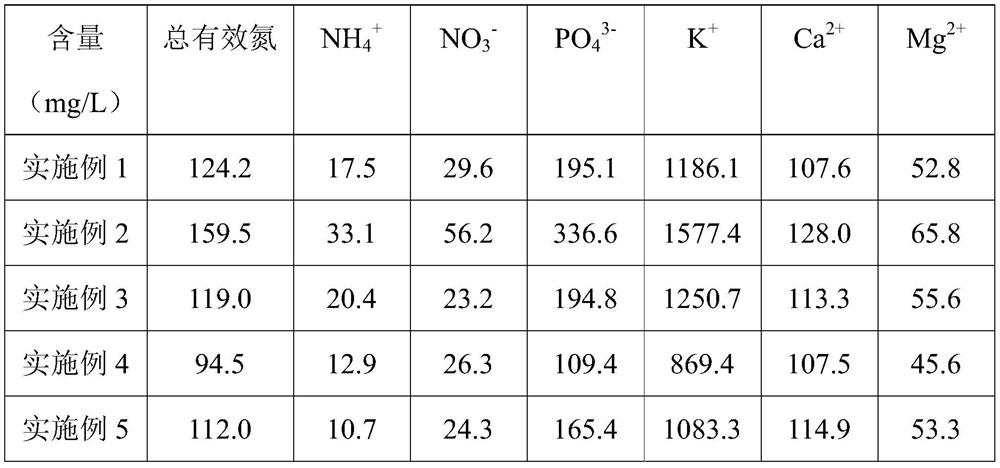

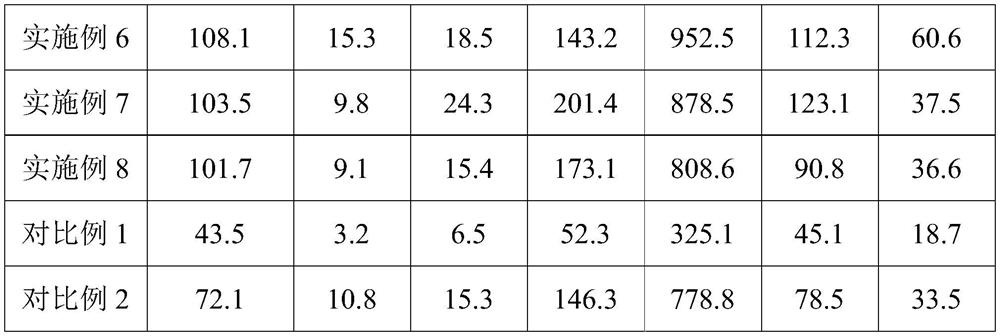

Examples

Embodiment 1

[0049] The present embodiment provides a kind of method that uses composite bacterial agent to prepare waste fruit ferment of grape, and concrete steps are:

[0050] (1) Grinding and sterilizing the waste grape fruit after washing with sterile water;

[0051] (2) 3kg grape waste fruit, 1kg brown sugar, 8kg sterile water are added in the fermentation container and mixed evenly;

[0052] (3) add the composite microbial inoculum of 1% volume ratio, described composite microbial inoculum is the activated culture fluid of Lactobacillus casei, saccharomycete and aspergillus, the volume ratio of three kinds of bacteria when described activated culture fluid initial is: 1 copy, 1 copy and 1 copy;

[0053] (4) Fermentation is carried out under anaerobic conditions, and the fermentation temperature is controlled to be 20° C., and the fermentation pH is 4.5;

[0054] During the fermentation process, keep the top cover of the fermentation container to vent one way and slightly stir to e...

Embodiment 2

[0057] The present embodiment provides a kind of method that uses composite bacterial agent to prepare waste fruit ferment of grape, and concrete steps are:

[0058] (1) Grinding and sterilizing the waste grape fruit after washing with sterile water;

[0059] (2) Add 5kg of waste grape fruit, 2kg of brown sugar, and 10kg of sterile water into the fermentation container and mix evenly;

[0060] (3) Add 2% volume ratio of composite microbial inoculum, wherein the volume ratio of Lactobacillus casei, yeast and Aspergillus is: 2 parts, 0.5 parts and 0.5 parts;

[0061] (4) Fermentation is carried out under anaerobic conditions, the fermentation temperature is 25°C, and the fermentation pH is 5.0;

[0062] During the fermentation process, the top cover of the fermentation container is kept to be exhausted in one direction and lightly stirred, and stirred once a day in the early stage and once a week in the later stage; the waste grape fruit enzyme product is obtained after 2 month...

Embodiment 3

[0065] The present embodiment provides a kind of method that uses composite bacterial agent to prepare waste fruit ferment of grape, and concrete steps are:

[0066] (1) Grinding and sterilizing the waste grape fruit after washing with sterile water;

[0067] (2) 4kg grape waste fruit, 2kg molasses, 8kg sterile water are added in the fermentation container and mixed evenly;

[0068] (3) Add 1% volume ratio of composite microbial inoculum, wherein the volume ratio of Lactobacillus casei, yeast and Aspergillus is: 1 part, 1 part and 0.5 part;

[0069] (4) Fermentation is carried out under anaerobic conditions, the fermentation temperature is 25°C, and the fermentation pH is 6.0;

[0070] During the fermentation process, the top cover of the fermentation container is kept to be exhausted in one direction and lightly stirred, and stirred once a day in the early stage and once a week in the later stage; the waste grape fruit enzyme product is obtained after 2 months of fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com