A kind of material for promoting nickel slag reduction and preparation method thereof

A technology for nickel slag and materials is applied in the field of materials and their preparation for promoting the reduction of nickel slag, which can solve the problems of difficult reduction of fayalite, and achieve the effects of reducing the difficulty of oxidation, reducing the resistance of mass transfer, and improving the reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] Based on the above principles, embodiments of the present invention are as follows:

[0023] The preparation method of the material that the present invention promotes nickel slag reduction is as follows:

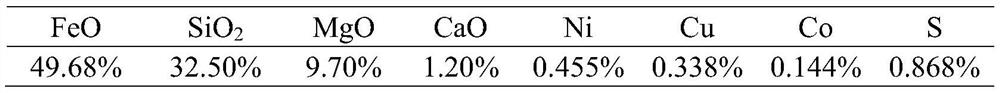

[0024] The nickel slag is crushed to ≤0.074mm, accounting for 85%, and compound oxidant is added to the nickel slag, and the added amount is 0.25%-3% of the mass of the nickel slag. After mixing, it is granulated by a disc pelletizing machine. 3-8mm balls, dry the balls. Select a low-concentration oxidizing atmosphere (the oxygen volume content in the weak oxidizing atmosphere is 3%-12%) for high-temperature roasting to improve the phase structure of the nickel slag and achieve the purpose of strengthening reduction, and the roasting temperature is controlled at 420-570 ° C. In the composite oxidant, by mass percentage, it includes 45%-85% solid oxidant, 8%-30% auxiliary agent and 7%-25% strengthening agent; the solid oxidant is potassium chlorate, potassium permang...

Embodiment 1

[0032] The nickel slag is crushed so that the particles with a particle size of ≤0.074mm account for at least 85% of the mass, and the composite oxidant is added to the nickel slag raw material according to the mass ratio of 0.25%, fully mixed and granulated by a disc pelletizing machine to obtain a particle size of 3-8mm the pellets, drying the pellets. In the composite oxidant, potassium chlorate is used as the solid oxidant, calcium hydroxide is used as the auxiliary agent, and lithium bicarbonate is used as the strengthening agent. Then, oxidative roasting was carried out on the briqueted raw materials in an atmosphere with an oxygen volume content of 8% and a pre-oxidation temperature of 450°C for 40 minutes. The calcined samples were reduced at 1200°C for 30 minutes and cooled. The total iron and metal iron contents were analyzed by sampling, and the metallization rate of the reduced product was calculated to be 80.6%.

Embodiment 2

[0034] The nickel slag is crushed so that the particles with a particle size of ≤0.074mm account for at least 85% of the mass, and the composite oxidant is added to the nickel slag raw material at a mass ratio of 0.75%, fully mixed and granulated by a disc pelletizing machine to obtain a particle size of 3-8mm the pellets, drying the pellets. In the composite oxidant, potassium permanganate is used as the solid oxidant, sodium hydroxide is used as the auxiliary agent, and lithium bicarbonate is used as the strengthening agent. In terms of mass percentage, the content of the solid oxidant is 65%, the content of the auxiliary agent is 15%, and the content of the strengthening agent is 13%. %. Then, in an atmosphere with an oxygen volume content of 8% and a pre-oxidation temperature of 420°C, the briqueted raw materials were subjected to oxidative roasting for 60 minutes. The calcined samples were reduced at 1200°C for 30 minutes and cooled. The total iron and metallic iron cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com