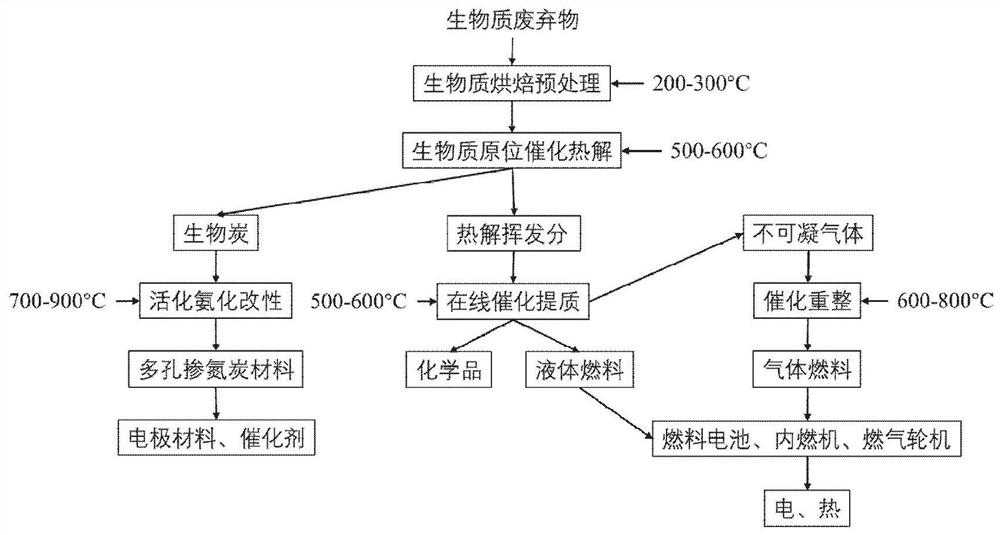

Biomass catalytic pyrolysis method for co-production of gas-liquid fuels, chemicals and carbon materials

A catalytic pyrolysis and biomass technology, applied in the field of biomass catalytic pyrolysis, can solve the problems of high cost, strong corrosion, single high-value products, etc., and achieve the effect of developed porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The embodiment of the present invention describes a method for biomass catalytic pyrolysis to co-produce gas-liquid fuels, chemicals and carbon materials. The method specifically includes the following steps:

[0064]S1: After pulverizing the bamboo, take 2g of biomass and pretreat it in a fixed-bed reactor (diameter: 45mm, length: 60mm). Raw materials after pretreatment;

[0065] S2: put the pretreated raw material into the first stage of a two-stage fixed-bed reactor, and carry out in-situ catalytic pyrolysis reaction under a nitrogen atmosphere. The catalyst is biochar, and the mass ratio of catalyst to biomass is 1:10. The catalytic pyrolysis temperature is 500°C, the reaction time is 10 minutes, the nitrogen flow rate is 200mL / min, and the pretreated raw materials are fully catalyzed for pyrolysis reaction;

[0066] S3: Pyrolysis volatiles are passed into the second-stage reactor, and under the action of a nitrogen-doped carbon catalyst, an online catalytic upgrad...

Embodiment 2

[0073] S1: After pulverizing the bamboo, take 2g of biomass and pre-cure it in a fixed-bed reactor (diameter 45mm, length 60mm). Raw materials after pretreatment;

[0074] S2: put the pretreated raw material into the first stage of a two-stage fixed-bed reactor, and carry out in-situ catalytic pyrolysis reaction under a nitrogen atmosphere. The catalyst is biochar, and the mass ratio of catalyst to biomass is 1:10. The catalytic pyrolysis temperature is 600°C, the reaction time is 10 minutes, the nitrogen flow rate is 200mL / min, and the pretreated raw materials are fully catalyzed for pyrolysis reaction;

[0075] S3: Pyrolysis volatiles are passed into the second-stage reactor, and under the action of a nitrogen-doped carbon catalyst, an online catalytic upgrading reaction is carried out. The mass ratio of nitrogen-doped carbon to biomass is 1:20, and the reaction temperature is 600°C. The time is 10 minutes;

[0076] S4: After the condensable volatile matter is cooled, phen...

Embodiment 3

[0082] S1: After pulverizing the bamboo, take 2g of biomass and pre-cure it in a fixed-bed reactor (diameter 45mm, length 60mm). Raw materials after pretreatment;

[0083] S2: Put the pretreated raw material into the first stage of a two-stage fixed-bed reactor, and carry out in-situ catalytic pyrolysis reaction under a nitrogen atmosphere. The catalyst is biochar, and the mass ratio of catalyst to biomass is 1:5. The catalytic pyrolysis temperature is 600°C, the reaction time is 30 minutes, the nitrogen flow rate is 200mL / min, and the pretreated raw materials are fully catalyzed for pyrolysis reaction;

[0084] S3: Pyrolysis volatiles are passed into the second-stage reactor, and under the action of nitrogen-doped carbon catalyst, an online catalytic upgrading reaction is carried out. The mass ratio of nitrogen-doped carbon to biomass is 1:5, and the reaction temperature is 600°C. The time is 30 minutes;

[0085] S4: After the condensable volatile matter is cooled, phenolic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com