Wool fiber mixing processing equipment

A processing equipment and wool fiber technology, applied in the field of wool fiber mixing processing equipment, can solve the problems that the raw material conveying mechanism cannot evenly convey the wool fiber, the lifting effect of the wool fiber lifting mechanism is not good, and the installation and connection of the fiber lifting mechanism are inconvenient, and the like. The effect of improving safety and convenience, simple structure and flexible mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

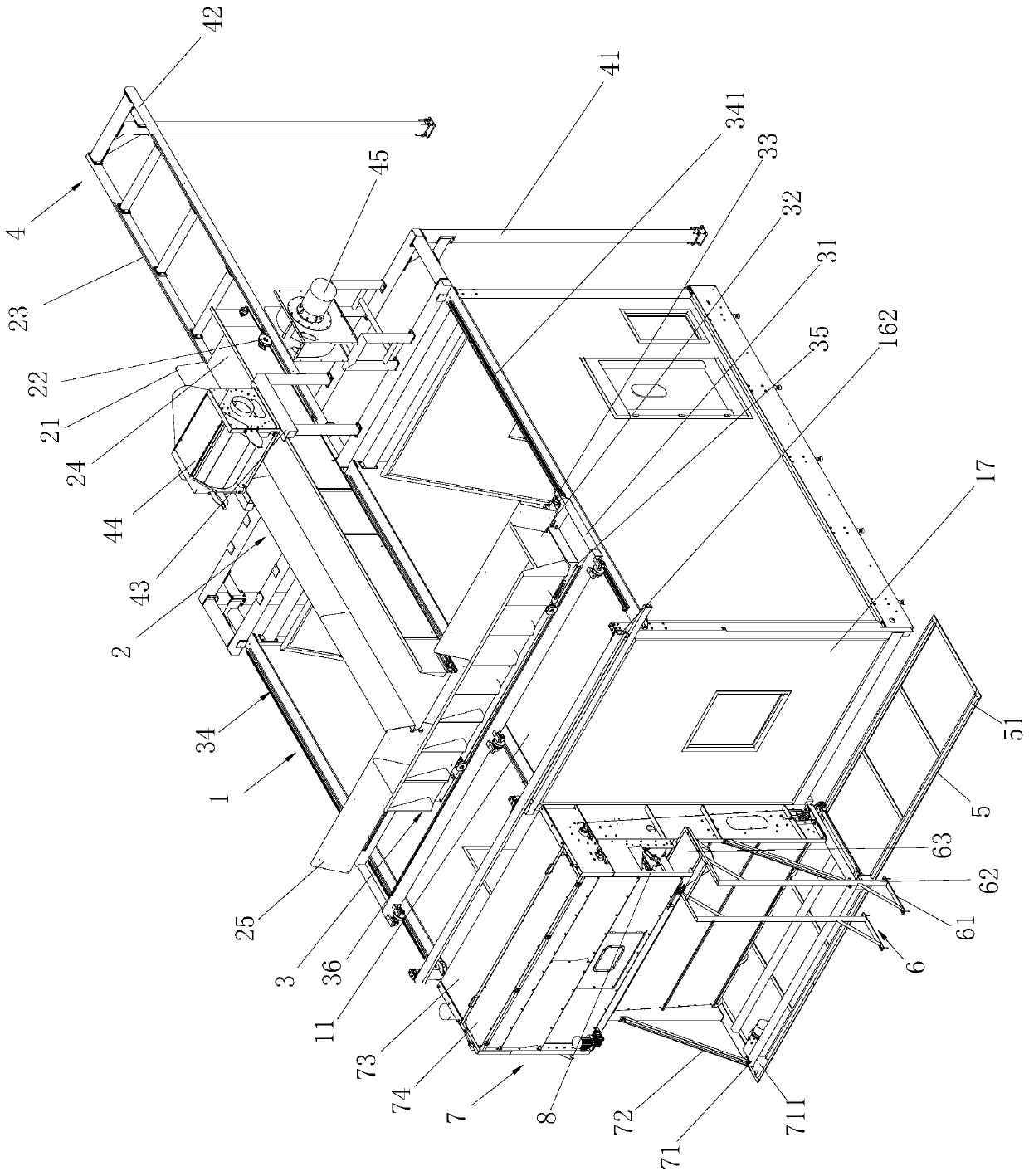

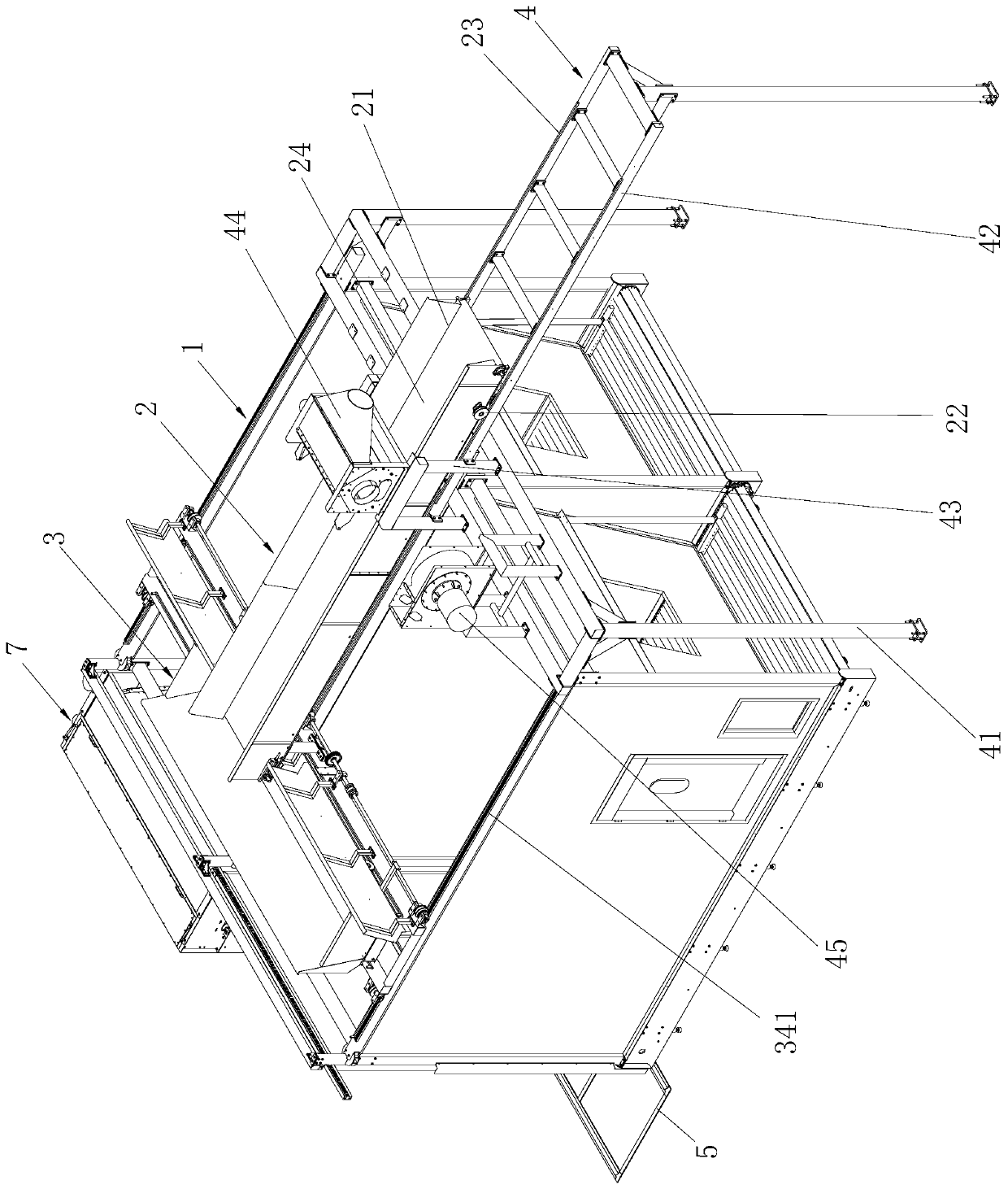

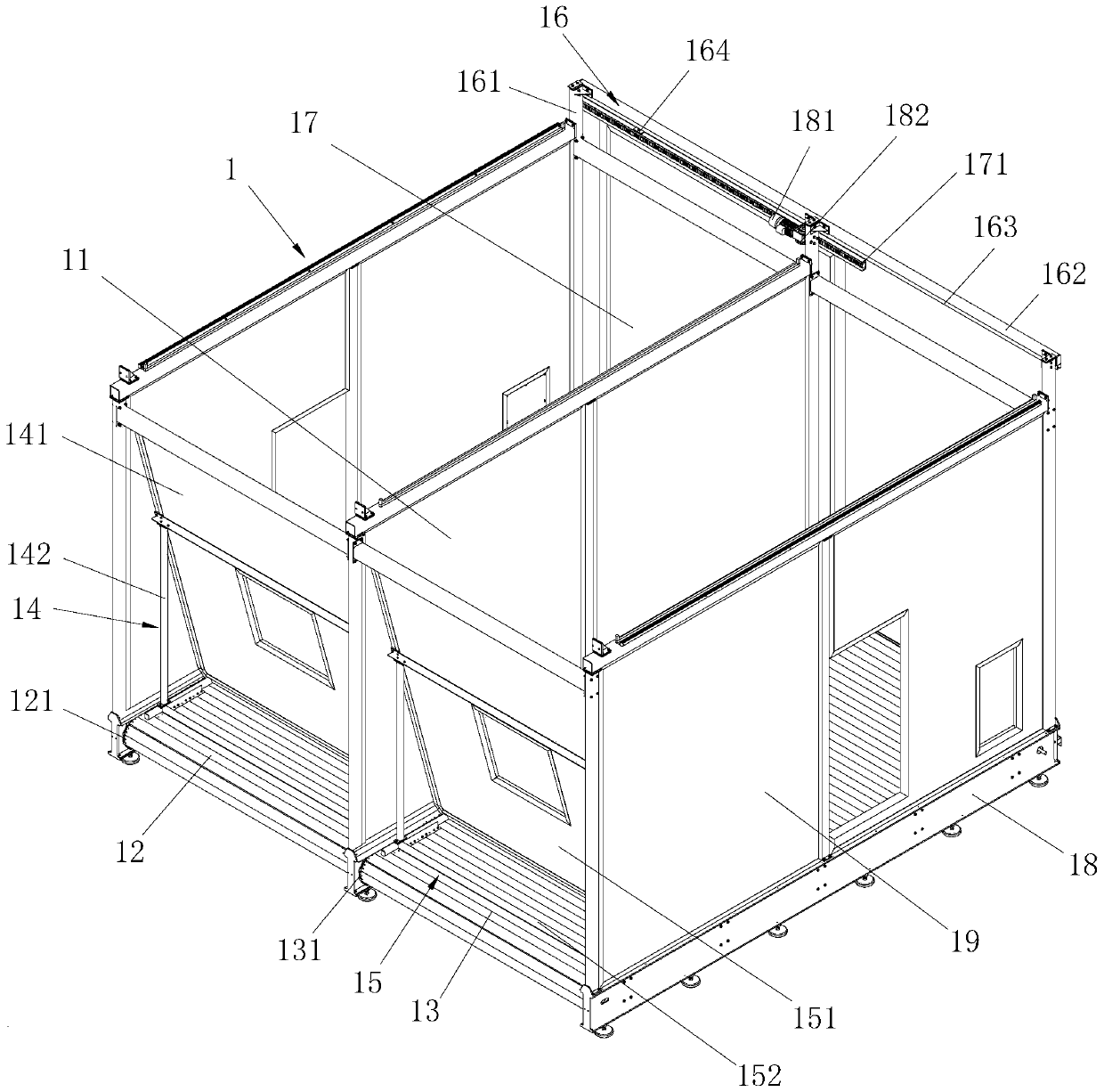

[0064] combine Figure 1 to Figure 8 , a wool fiber mixing processing equipment, including wool fiber conveying equipment, wool fiber storage equipment and wool fiber extraction equipment, wool fiber storage equipment includes and wool bin 1, and the middle part of wool bin 1 is provided with a first partition plate 11, The first bottom flat curtain 12 and the second bottom flat curtain 13 are arranged in the wool bin 1 on both sides of the first dividing plate, and the first bottom flat curtain 12 is connected with the first rear door assembly 14, and the second bottom flat curtain 12 Connected with the second rear door assembly 15. The front end of the hair bin 1 is connected with a first sliding door track mechanism 16, and the first front door 17 is slidably connected to the lower end of the first sliding door track mechanism 16.

[0065] The wool fiber conveying equipment comprises a vertical feeding mechanism 2 and a horizontal feeding mechanism 3, and the rear end of t...

Embodiment 2

[0107] combine Figure 1 to Figure 8 , a kind of wool fiber mixing processing equipment, comprises wool fiber conveying equipment, wool fiber storage equipment, wool fiber storage equipment comprises and wool warehouse 1, and the middle part of wool warehouse 1 is provided with the first dividing plate 11, the first dividing plate The first bottom flat curtain 12 and the second bottom flat curtain 13 are provided in the wool bin 1 on both sides, the first bottom flat curtain 12 is connected with the first rear door assembly 14, and the second bottom flat curtain 12 is connected with the second bottom flat curtain 12. Rear door assembly 15. The front end of the hair bin 1 is connected with a first sliding door track mechanism 16, and the first front door 17 is slidably connected to the lower end of the first sliding door track mechanism 16.

[0108] The wool fiber conveying equipment comprises a vertical feeding mechanism 2 and a horizontal feeding mechanism 3, and the rear en...

Embodiment 3

[0112] combine Figure 1 to Figure 8 , a wool fiber mixing processing equipment, including wool fiber conveying equipment, wool fiber storage equipment and wool fiber extraction equipment, wool fiber storage equipment includes and wool bin 1, and the middle part of wool bin 1 is provided with a first partition plate 11, The first bottom flat curtain 12 and the second bottom flat curtain 13 are arranged in the wool bin 1 on both sides of the first dividing plate, and the first bottom flat curtain 12 is connected with the first rear door assembly 14, and the second bottom flat curtain 12 Connected with the second rear door assembly 15. The front end of the hair bin 1 is connected with a first sliding door track mechanism 16, and the first front door 17 is slidably connected to the lower end of the first sliding door track mechanism 16.

[0113] The wool fiber conveying equipment comprises a vertical feeding mechanism 2 and a horizontal feeding mechanism 3, and the rear end of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap