Ship lock floating access door device and automatic sinking and floating control method

An access door and floating technology, which is applied in the ship lifting device, ship lock, electrical program control and other directions, can solve the problem of continuous water inflow in the water conveying gallery, unfavorable attitude adjustment of the inspection door, and damage to the hydraulic structure of the inspection gallery of the ship lock working gate. Troubleshooting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

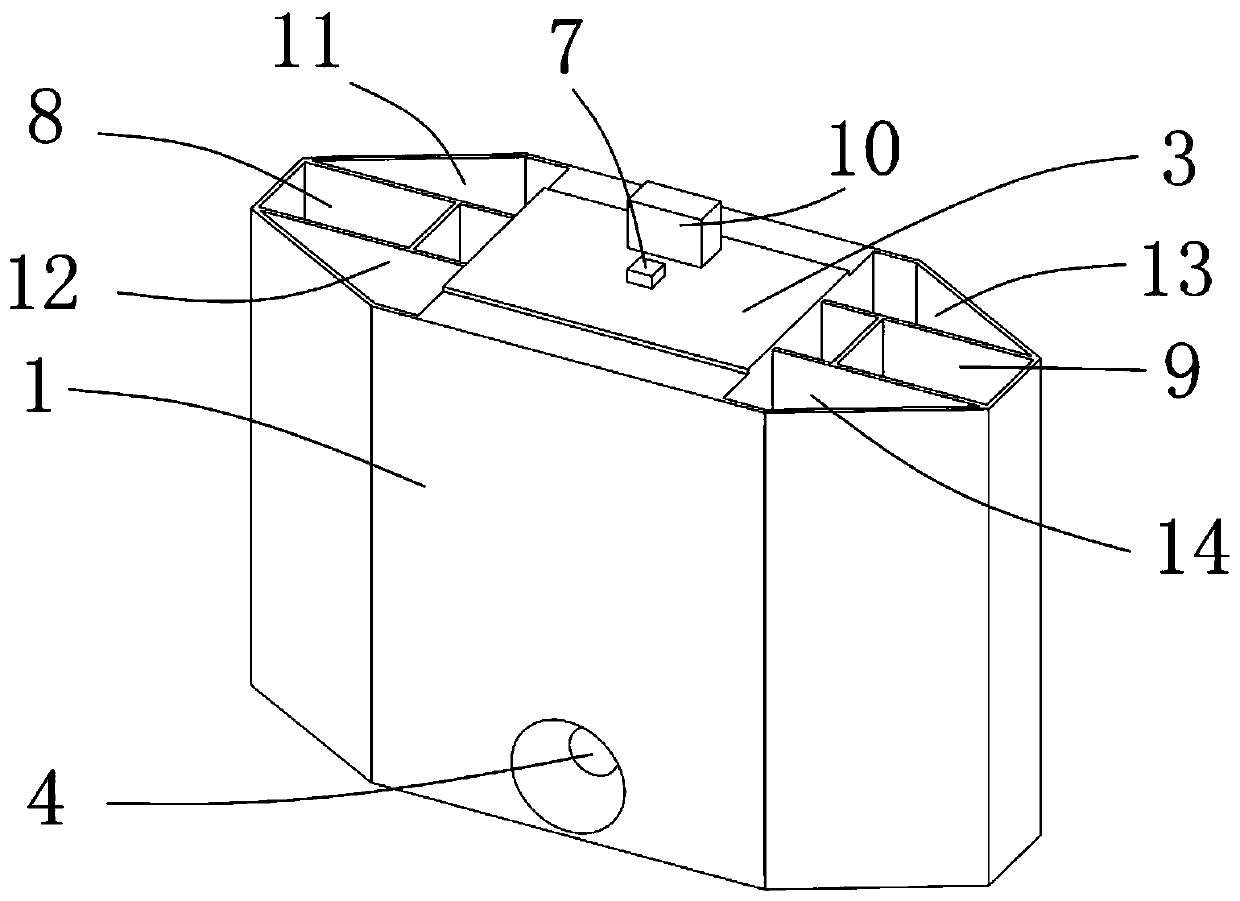

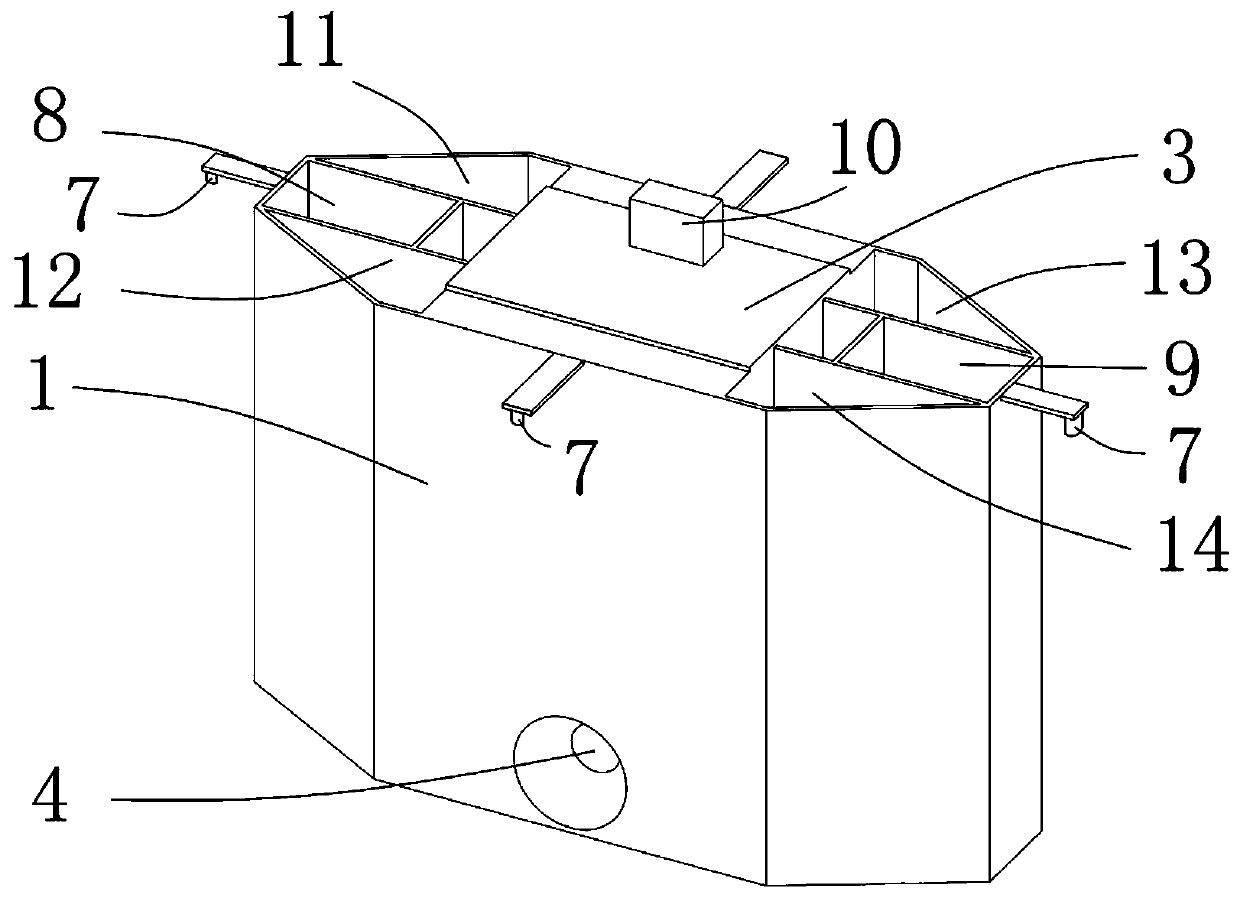

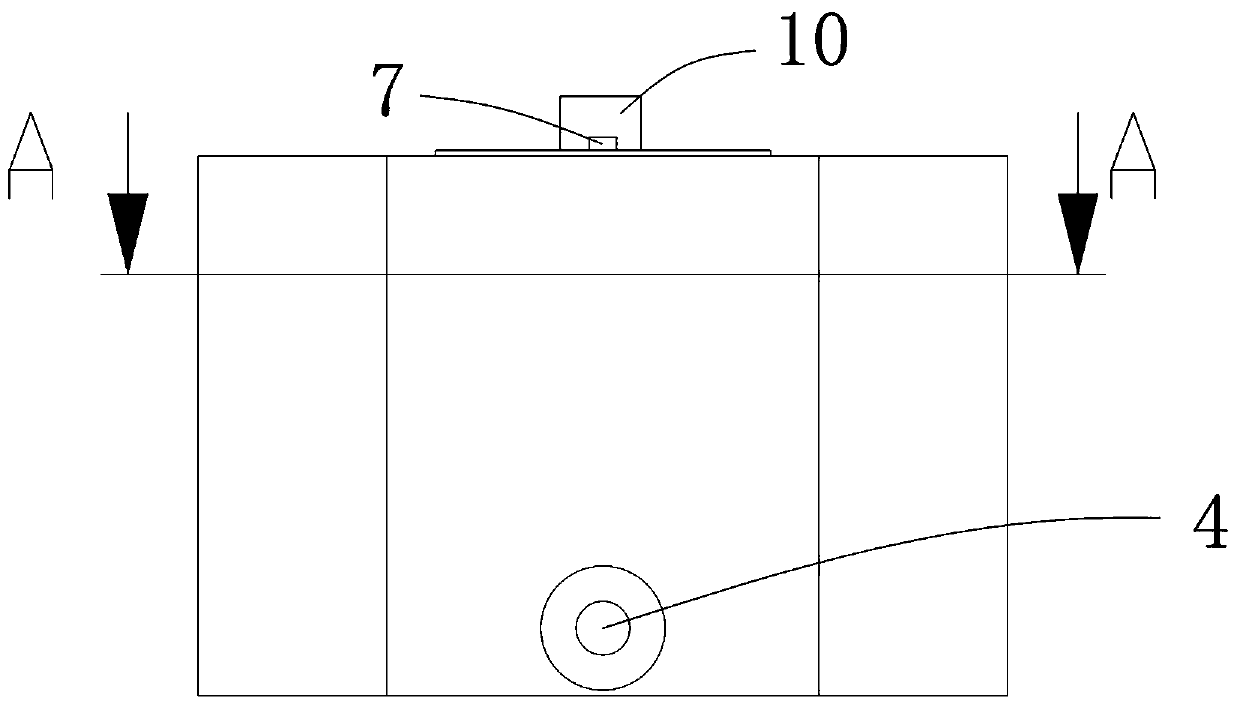

[0036] like Figures 1 to 4 As shown in , a floating inspection door device for a ship lock includes a floating inspection door 1 and its control device 2. The floating inspection door 1 is a box-type gate. There are side water tanks and regulating water tanks on both sides of the cabin 3, and a main water pipe 4 is provided under the central water tank 3. The main water pipe 4 runs through the lower part of the inspection door and is connected with the central water tank 3. The bottom water supply pipe is connected to the central water tank 3, and the side of the floating inspection door 1 is provided with a drain pipe 5 and a drainage pump 6 connected to the main water pipe 4. There is a fixedly connected attitude sensing device 7 in the middle of the upper part. The control device 2 controls the ups and downs and attitude of the floating inspection door 1 through the electric valve and the inclination sensor 7 connected to it. The control device 2 is placed on the floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com