Device used for reinforcing steel bar sleeve connection and construction method

A technology of steel sleeves and steel bars, which is applied in the processing of building materials, structural elements, building components, etc., can solve problems such as unreliable twisting, and achieve the effect of ensuring safety and stability, solving construction technical problems, and overcoming over-twisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

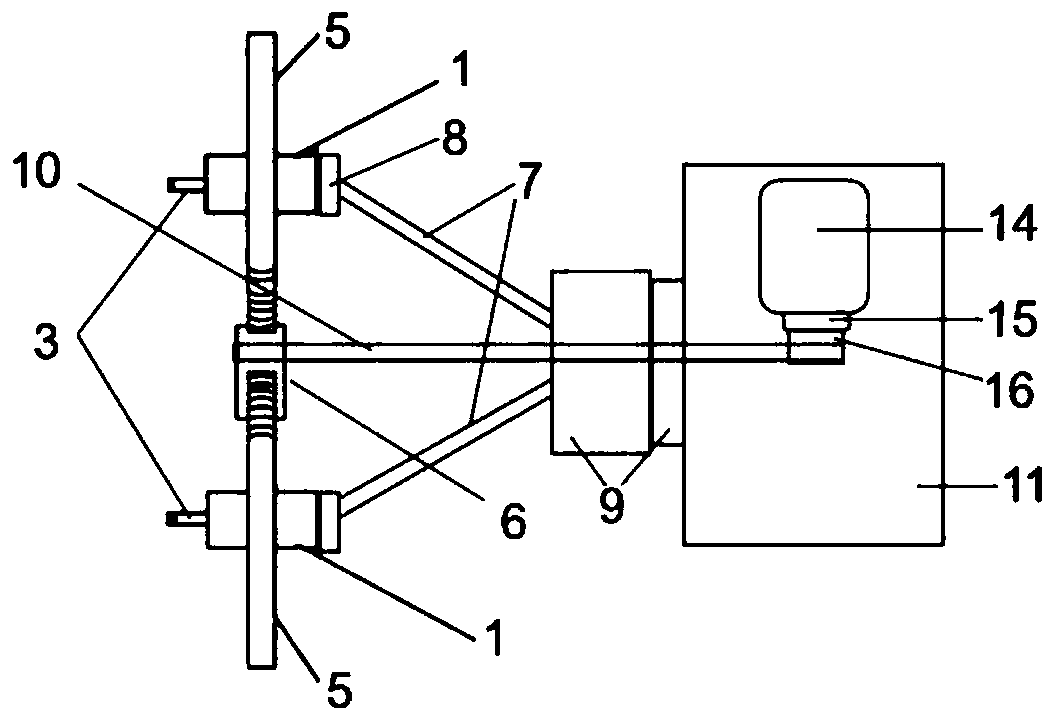

[0025] A device for connecting steel bar sleeves, including a first clamping device, a second clamping device, a detachable conveyor belt 10, a motor 14, a reducer 15, the first clamping device and the second clamping device The first clamping device and the second clamping device are connected with a notch 2 on the top surface, and the two ends of the notch 2 are open. The first clamping device and the second clamping device respectively clamp a steel bar . The motor 14 is connected on the motor base 11 .

Embodiment 2

[0027] Based on embodiment 1, embodiment 2 also includes a tightening device, which includes two tightening blocks 8, in the form of The top tight bar 7 and the jack 9 that type arranges. Jack adopts a kind of in the prior art, for example can adopt hydraulic jack.

Embodiment 3

[0029] Based on embodiment 1 or embodiment 2, embodiment 3 enumerates several additional technical features, and embodiment 1 or embodiment 2 can choose one or most of them in combination to form multiple new and different technical solutions.

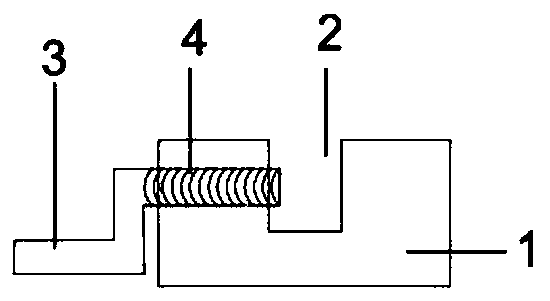

[0030] Preferably, in the above-mentioned device for connecting steel bar sleeves, the first clamping device and the second clamping device both include a fixed block 1 and a clamping rod. The fixed block 1 is provided with a horizontal channel, and the inner wall of the channel is engraved with internal thread, the clamping lever is Type, one end is engraved with the external thread 4 of the clamping rod, and the other end is a handle 3, and the clamping rod is matched with the channel thread.

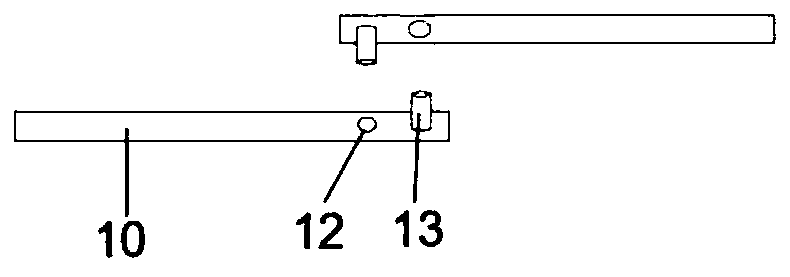

[0031] Preferably, in the above-mentioned device for connecting steel bar sleeves, the detachable conveyor belt 10 includes a conveyor belt, and the two ends of the conveyor belt 10 are connected with pin holes 12 and pin shafts 13 in turn, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com