External wall painting hanging basket structure for building construction

A technology for building construction and exterior walls, applied in the field of hanging baskets, can solve the problems of time-consuming and laborious, self and contact surface damage, etc., and achieve the effect of reducing cumbersomeness, reducing the degree of damage, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

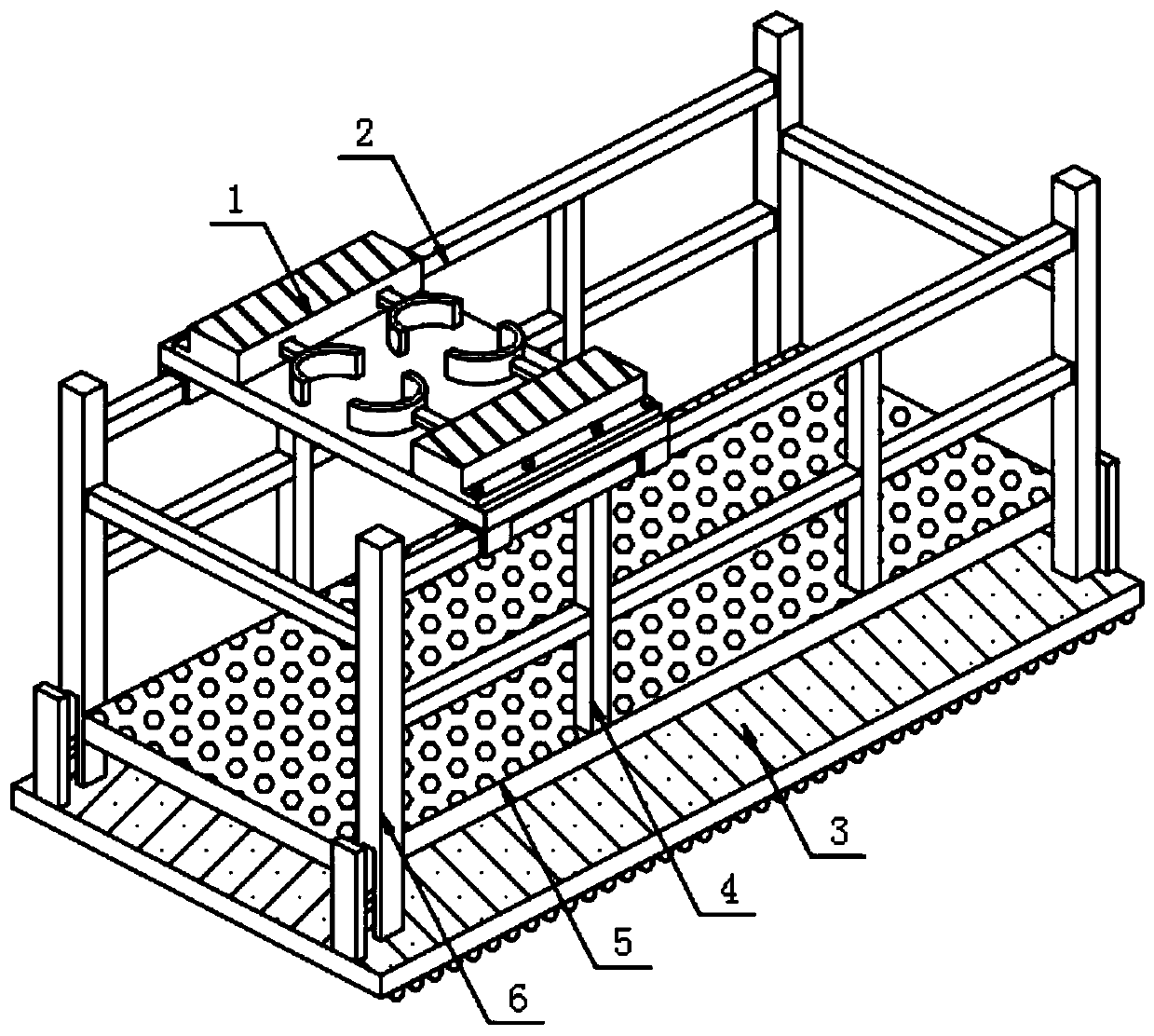

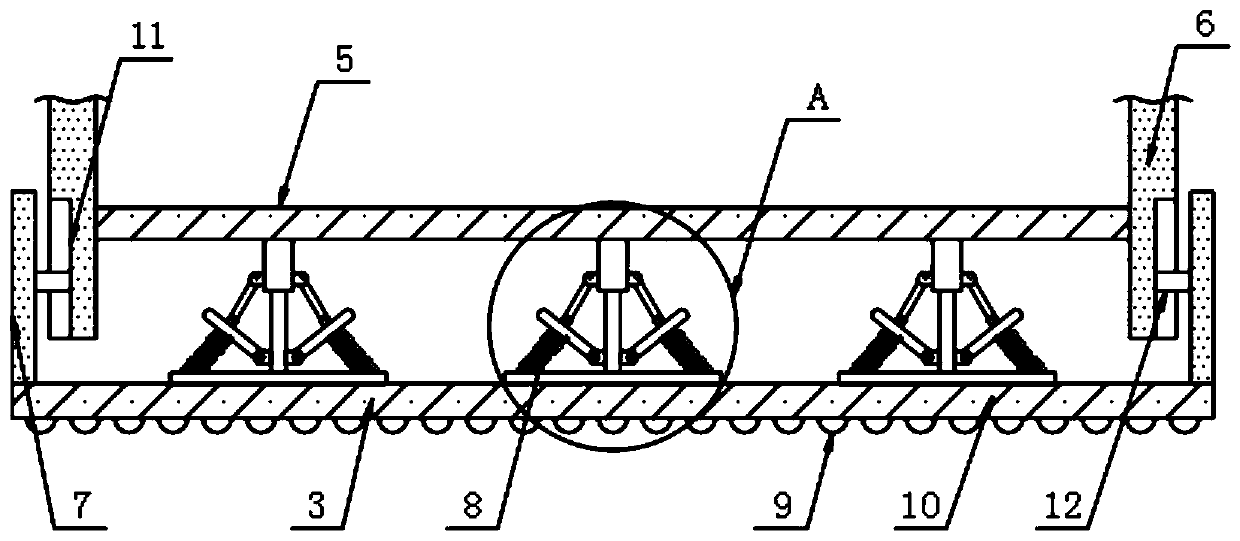

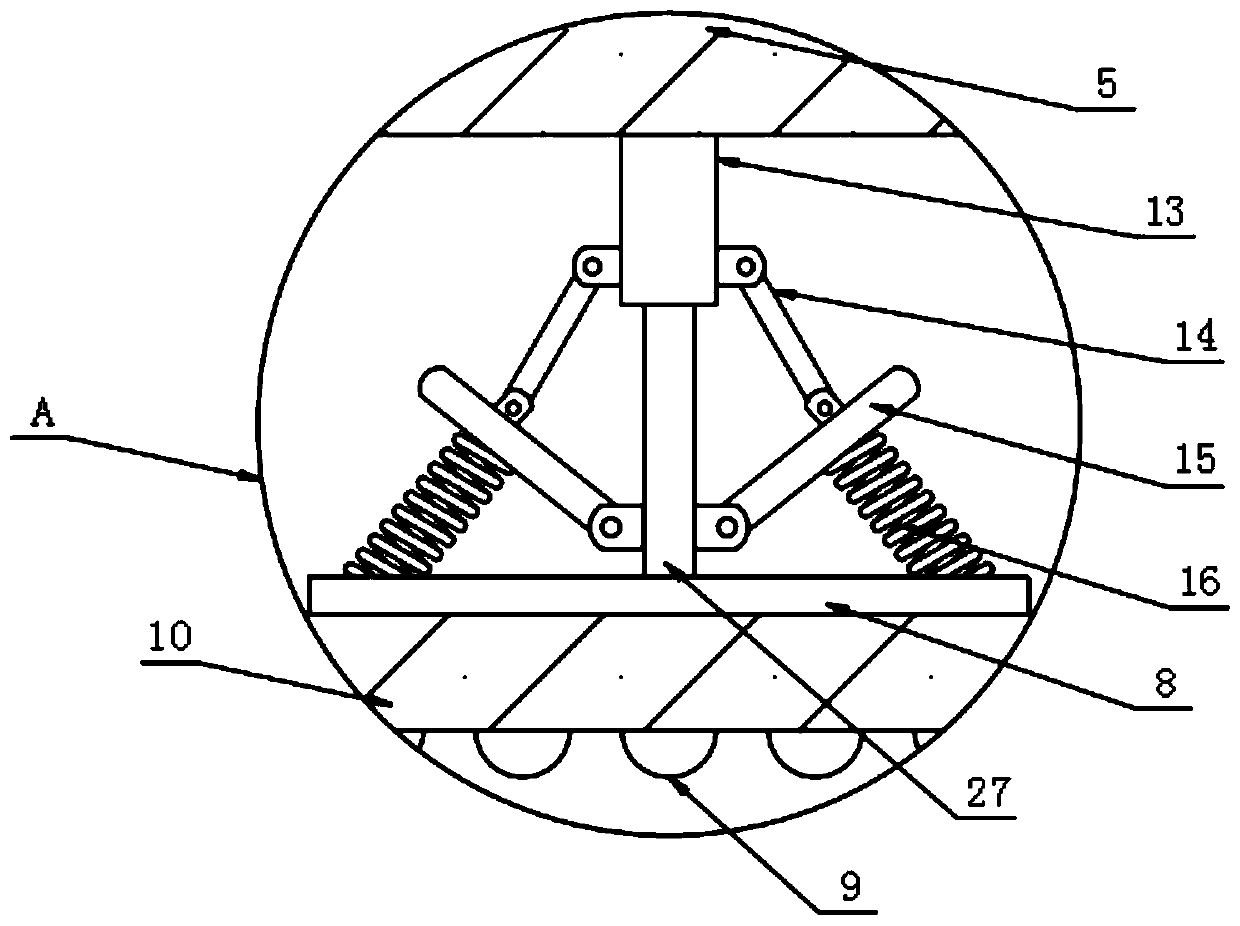

[0022] see Figure 1~5 , in an embodiment of the present invention, a hanging basket structure for exterior wall painting for building construction includes a support plate 5, installation rods 6 affixed to the four corners of the support plate 5, affixed to the upper surface of the support plate 5 and The protective bracket 4 perpendicular to itself and the connecting rod 2 fixed on the top of the protective bracket 4 are connected above the connecting rod 2 with a placement component 1 that can slide horizontally along its own length. The placement component 1 includes a placement plate 17. The first fixed seat 18, the first retaining rod 19, the first clamping plate 20, the second clamping plate 21, the second retaining rod 22, the second retaining seat 23 and the frame 24, the upper surface of the placing plate 17 is composed of The first fixed seat 18 and the second fixed seat 23 are fixed in turn in the front of the rear, and the four corners of the lower surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com