A kind of door-heat exchanger integrated multi-layer door and equipment with multi-layer door

A door and equipment technology, applied in the field of power and communication equipment operating environment adjustment, can solve problems such as affecting the transportation of kilometers, difficult to install, and increasing the overall height of the cabin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

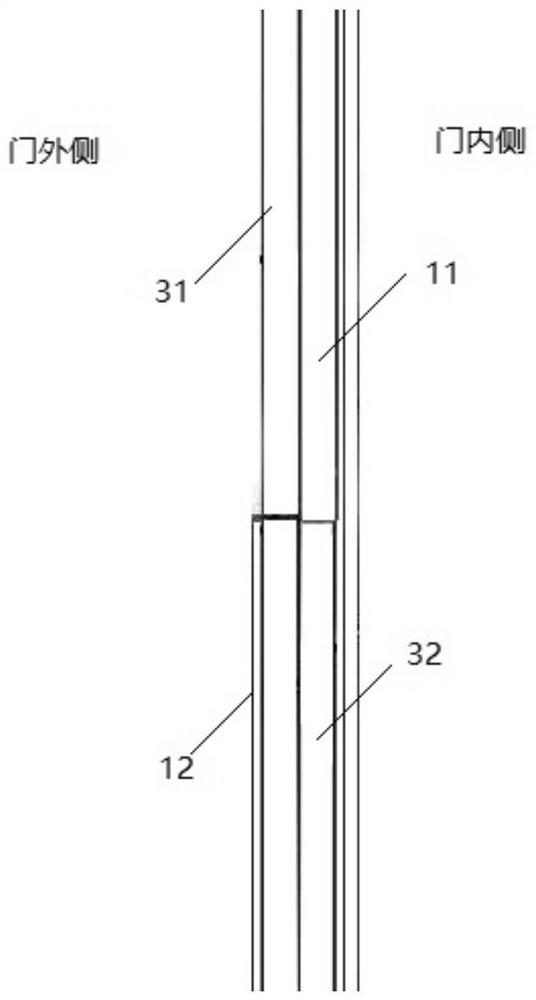

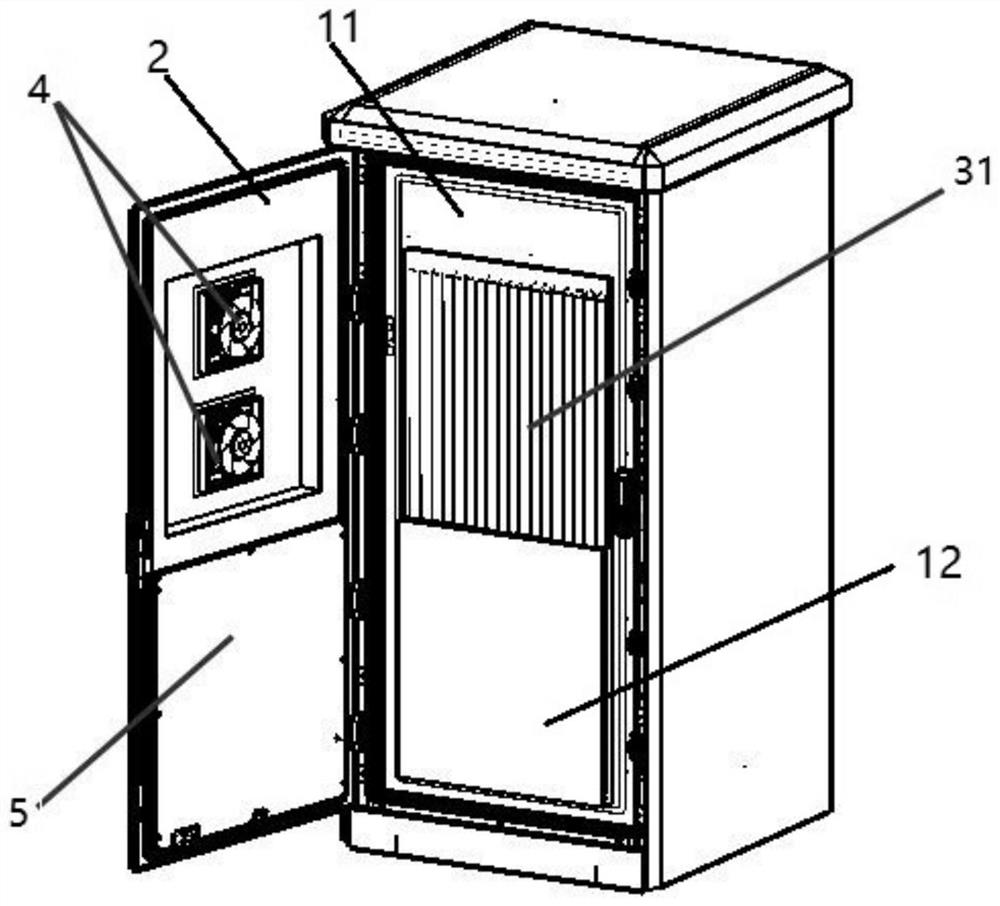

[0031] This embodiment is a kind of multi-layer door, refer to figure 1 and figure 2 As shown, the multi-layer door includes an outer door 2, an inner door 1 and a gravity heat pipe mechanism; the gravity heat pipe mechanism includes a heat releasing section 31 and a heat absorbing section 32;

[0032] The gravity heat pipe mechanism runs through and seals the middle of the inner door in the height direction, so that the heat release section 31 of the gravity heat pipe mechanism is located between the outer door and the inner door, and the heat absorption section 32 is located inside the inner door;

[0033] The outer door corresponding to the heat release section of the gravity heat pipe mechanism is provided with a heat exchange mechanism.

[0034] In this example:

[0035] Such as figure 2 As shown, the side of the outer door facing the heat release section of the gravity heat pipe mechanism is recessed to form a heat exchange chamber, and two heat exchange fans 4 are ...

Embodiment 2

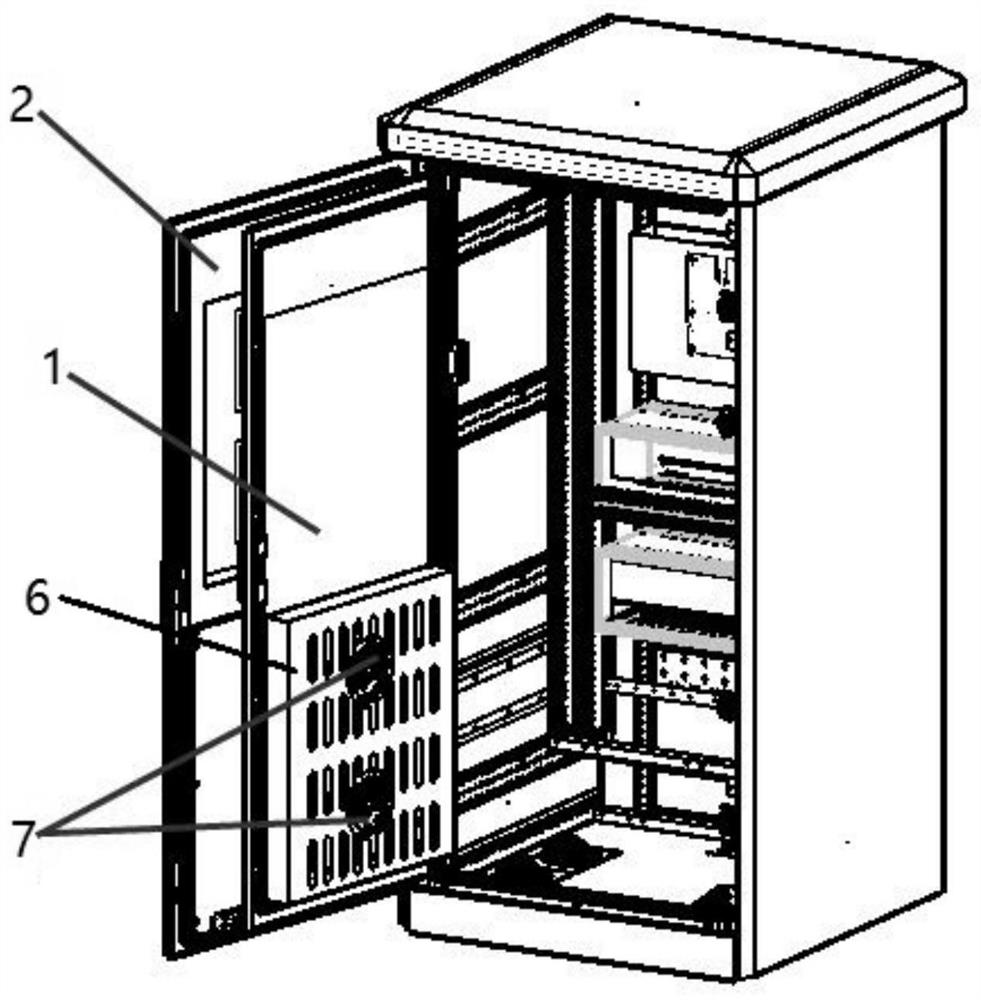

[0045] This embodiment is a cabinet or prefabricated cabin with multi-layer doors, refer to Figure 2 to Figure 6 As shown, the equipment is a cabinet, and the cabinet includes a cabinet body and a cabinet door that are rotatably connected, and the cabinet door is the multi-layer door of Embodiment 1.

[0046] Such as Figure 5 As shown, in order to further improve the heat exchange efficiency of the gravity heat pipe, a heat exchange circulation fan 9 is provided in the cabinet, which can realize the heat circulation of the entire space in the cabinet.

[0047] In this embodiment, the cabinet with double-layer doors can realize the following functions during normal operation: Figure 6 The internal and external heat cycle shown has high heat exchange efficiency.

[0048] If the equipment is a prefabricated cabin, the cabin includes a rotatably connected cabin body and a cabin door, and the cabin door is a multi-layer door. A heat exchange circulation fan is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com