Turbocharger volute

A turbocharger and volute technology, applied in the direction of machines/engines, gas turbine devices, engine components, etc., can solve the problems of large turbocharger performance loss, difficult balance between turbocharger performance and reliability, and achieve performance impact Low, easy to process and manufacture and control detection, and reduce the effect of collision risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

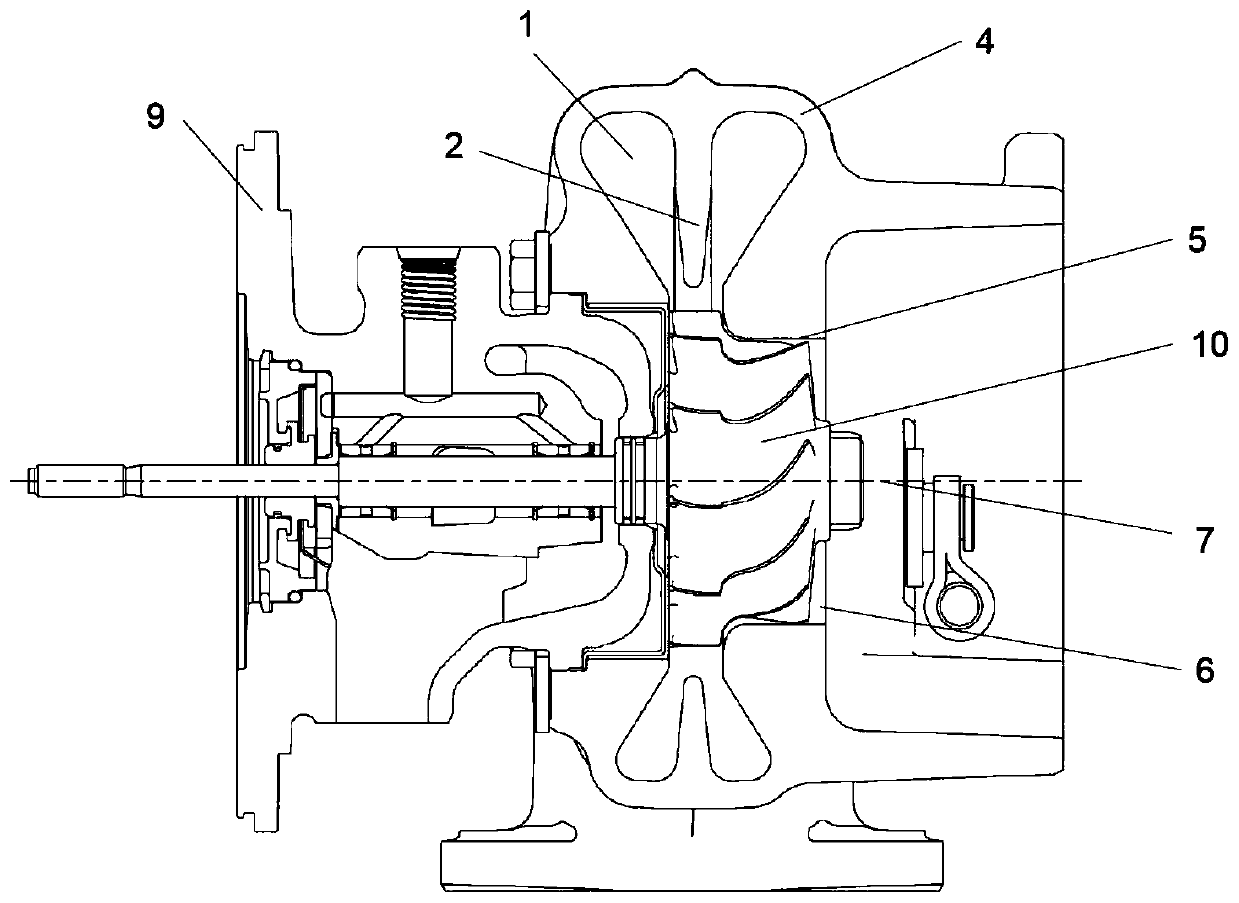

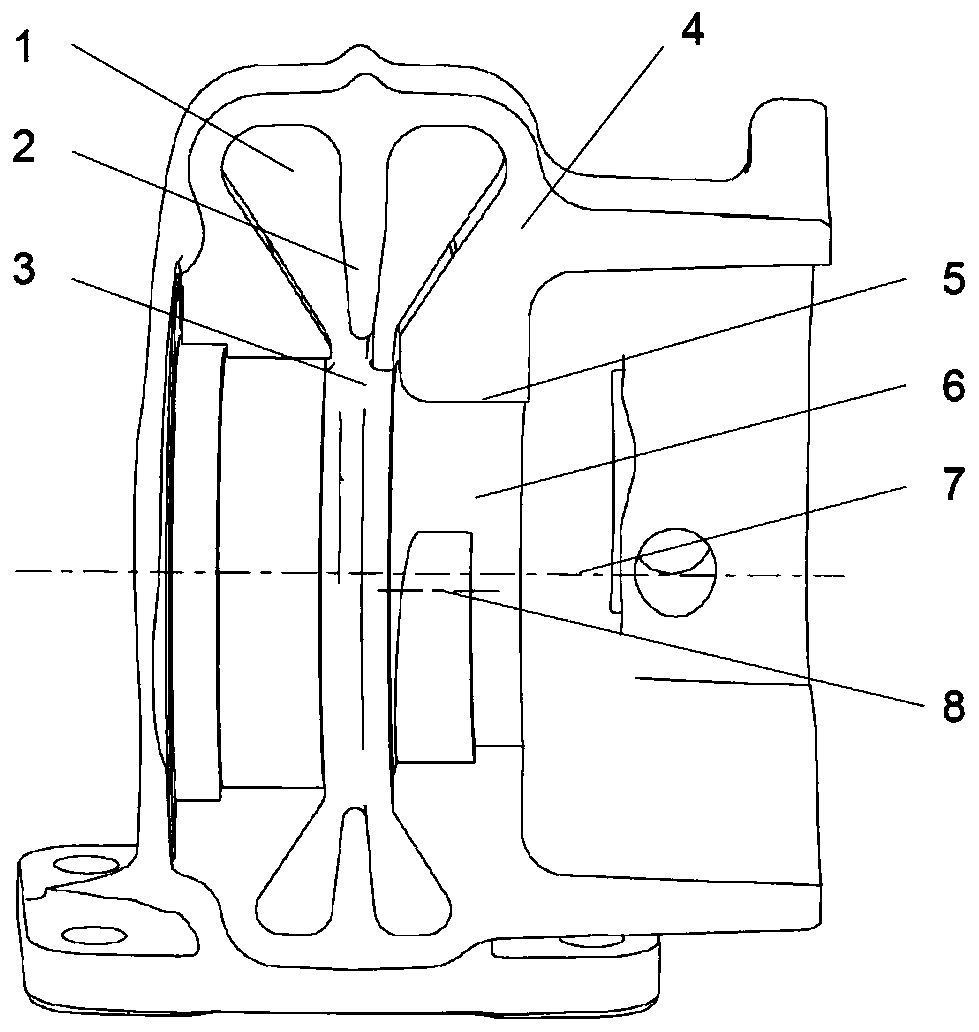

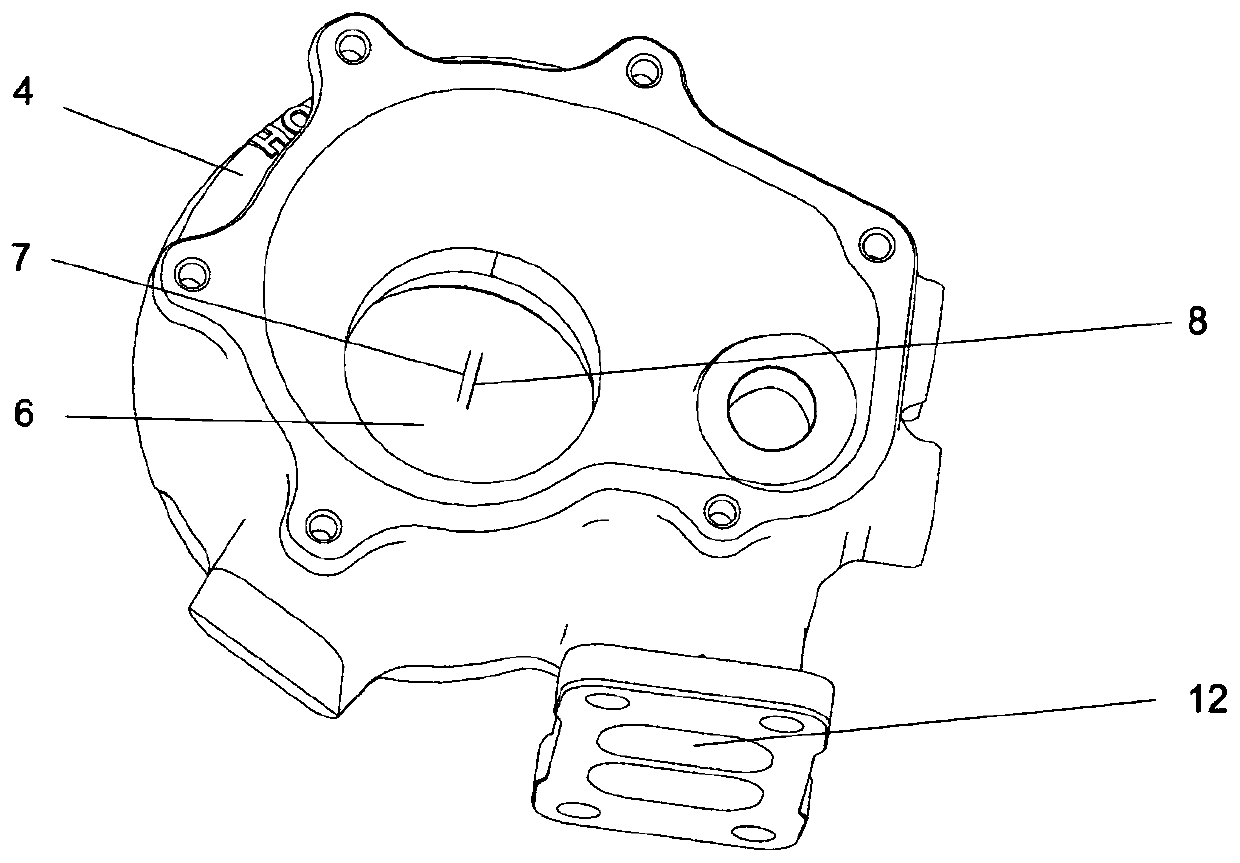

[0020] Such as Figure 2~6 As shown, a turbocharger volute of the present invention includes a volute casing 4, a volute flow passage 1 is arranged in the volute casing 4, a partition wall 2 is arranged in the volute flow passage 1, and the volute casing A volute profile 5 is also set inside the body 4, and the inner side of the volute profile 5 forms a volute outlet 6, and the volute tongue 3 is arranged in the volute housing 4 corresponding to the inner part of the volute outlet 6, and the volute outlet 6 rotates centrally The central axis 7 is set in the area; a part of the ring on the inner wall of the volute profile 5 is coaxially arranged with the central axis 7, and a part of the ring on the other side of the inner wall of the volute profile 5 is eccentrically arranged with the central axis 7. At this time, the The central axis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com