Self-locking anti-loosening rubber gasket and screw thread pair thereof

A technology of rubber washers and anti-loose washers, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the problems of high machining accuracy requirements, inconvenient disassembly, decreased preload force, etc., and achieves low machining accuracy requirements and structural Simple and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

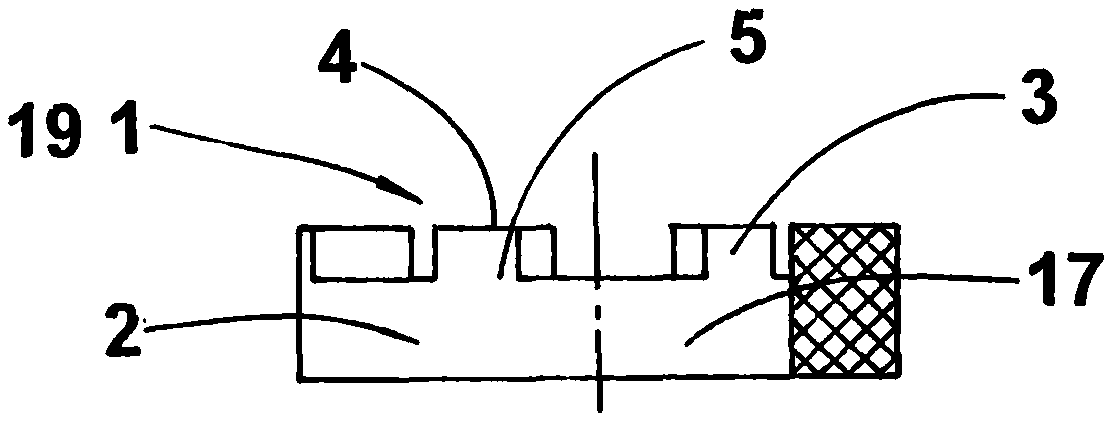

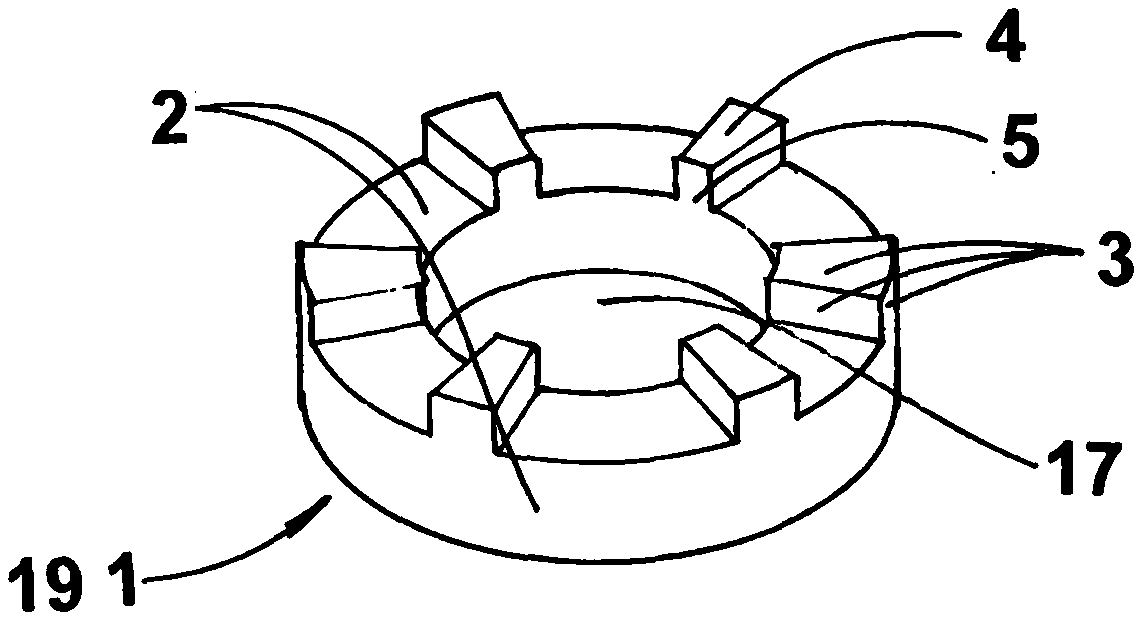

[0032] Figure 1~2 Among them, it is a self-locking and anti-loosening rubber washer 1 of the present invention. At least one claw 3 is provided on one side of the rubber washer base ring 2 with a rectangular cross section. In the figure, there are six claws 3. The protruding rectangular The rubber claws 3 in the vertical section, the claw roots 5 are evenly distributed on one side of the base ring 2, and are integrated with the base ring 2. In order to facilitate the demoulding production, the cross section of the claw roots 5 reaches the claw The cross-section of end 4 may gradually become smaller.

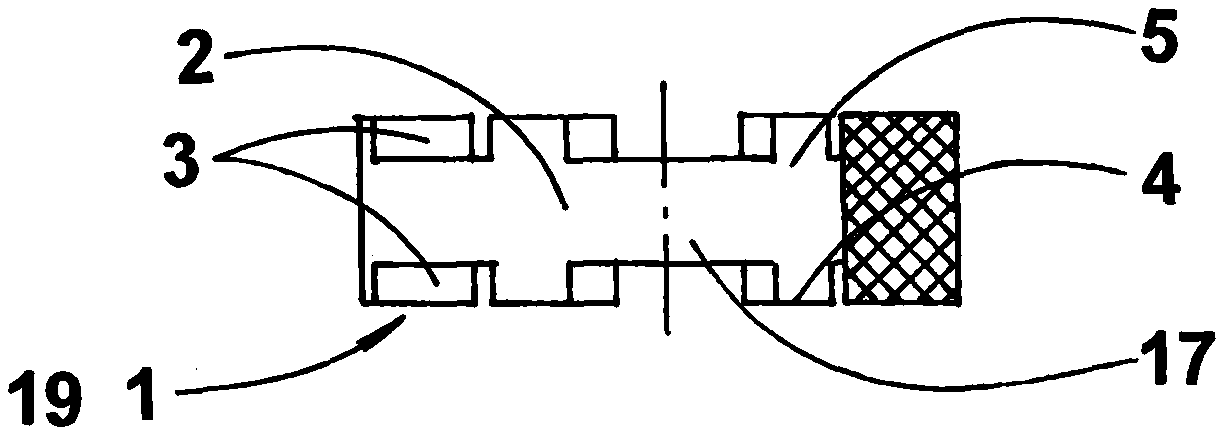

[0033] Figure 3-4Among them, is another self-locking and anti-loosening rubber washer 1 of the present invention. At least one claw 3 is respectively provided on both sides of the rubber washer base ring 2 with a rectangular cross section. In the figure, 6 protrusions are evenly distributed on both sides. The rectangular longitudinal section of the rubber claw 3, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com