Fully-lined ceramic three-way ball valve and valve ball structure thereof

A technology of three-way ball valves and ceramic valves, which is applied in the direction of valve housing structure, multi-way valves, valve details, etc., can solve problems such as easy fracture, and achieve the effects of reducing stress concentration, high wear resistance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

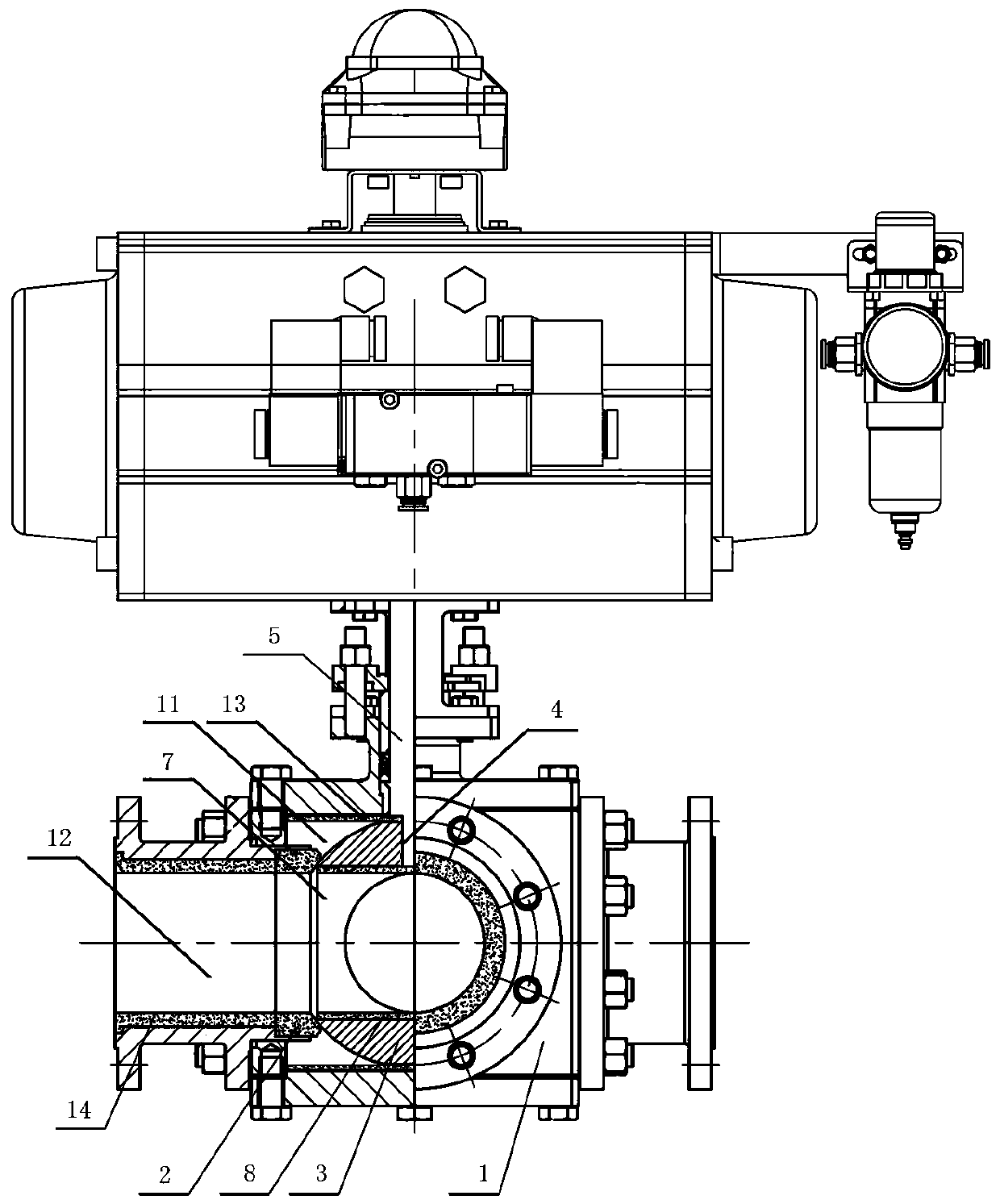

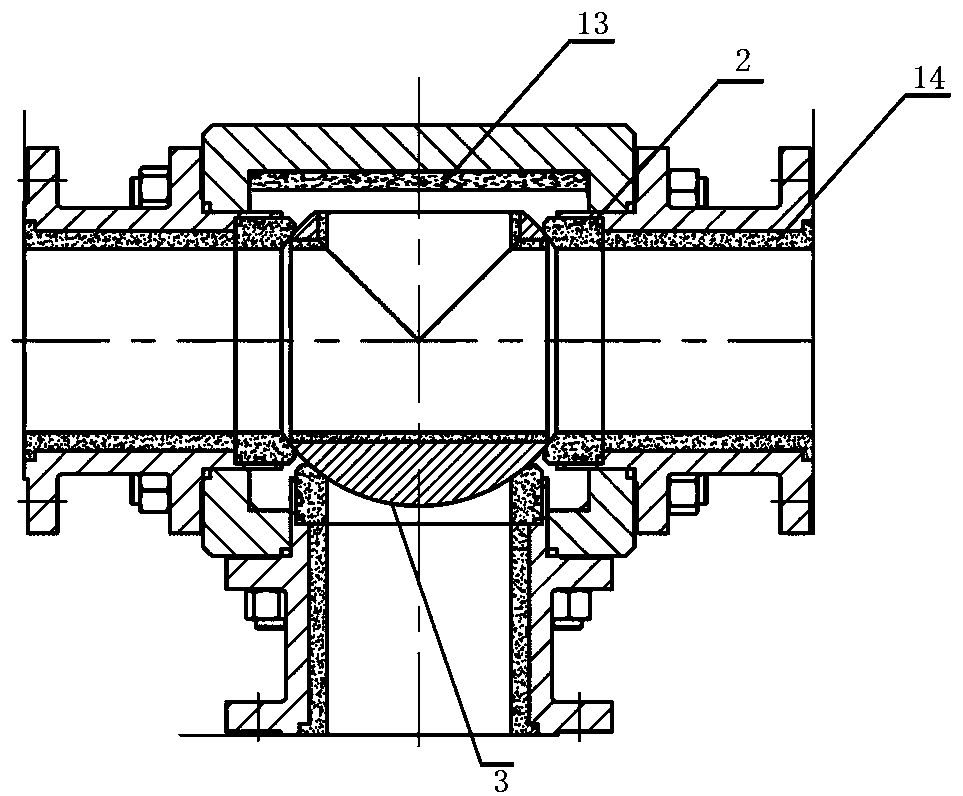

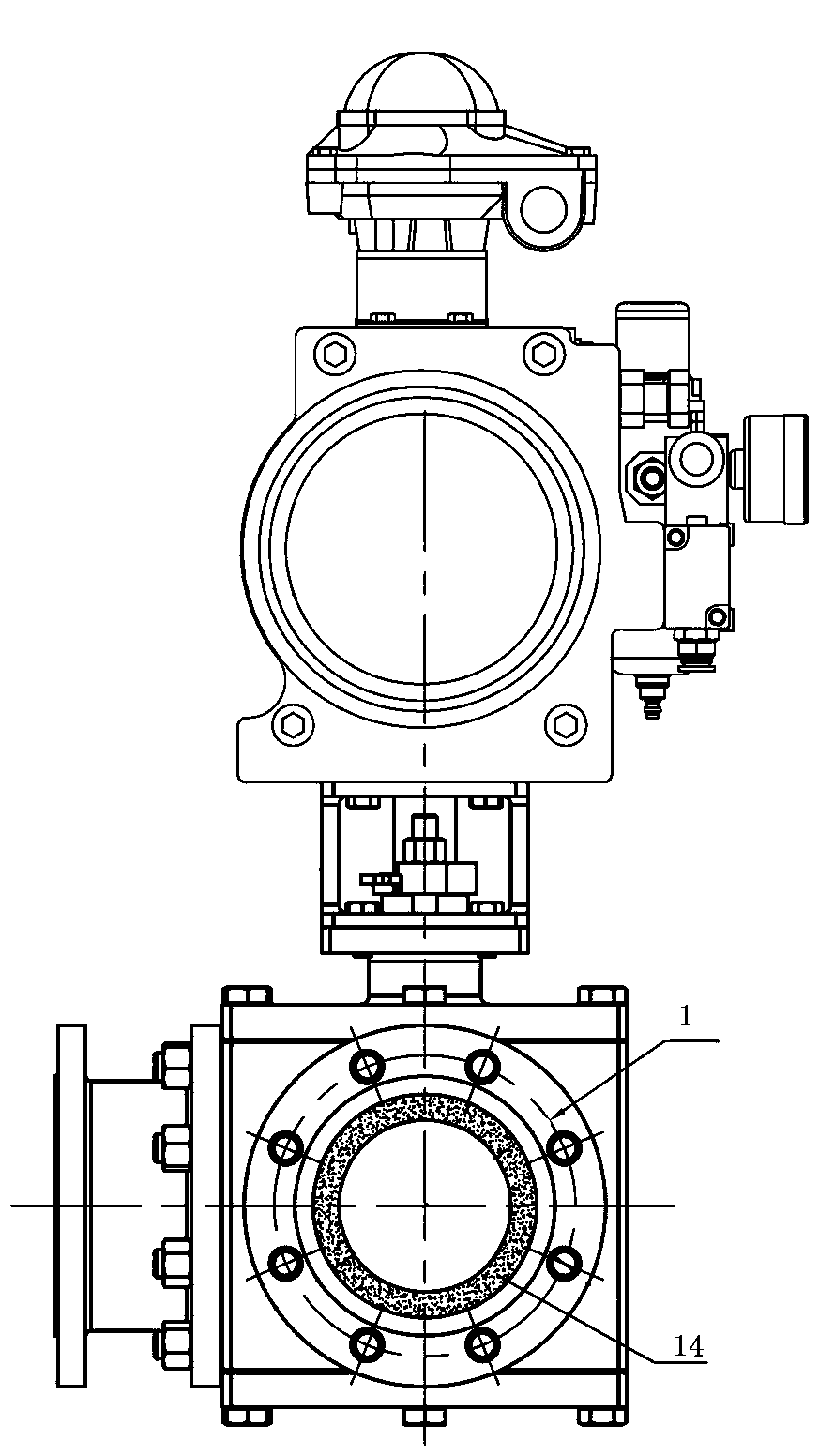

[0028] A fully lined ceramic three-way ball valve, such as Figure 1-3 As shown, it includes a valve body 1, a valve seat 2 and a valve ball 3. The valve body is provided with a valve cavity 11 and a flow channel 12. The inner wall of the valve cavity is provided with a valve cavity liner 13 through precision machining. The precision machining sleeve is provided with a flow channel lining 14, the valve cavity lining and the flow channel lining are all ceramic linings, the valve seat 2 is a ceramic valve seat, the valve cavity lining 13, the flow channel lining 14 and the valve seat form a When high temperature or highly corrosive fluid flows through the ball valve, the fluid contacts the ceramic lining and ceramic valve seat, thereby protecting the valve body 1 from contact with the fluid.

[0029] The valve ball 3 is a ceramic valve ball. Because the interior of the ceramic is bonded by covalent bonds, its bonding force is very strong, so the ceramic has a high hardness and h...

Embodiment 2

[0033] Embodiment 2: A full-lined ceramic three-way ball valve of this embodiment will be described centering on the differences from Embodiment 1.

[0034] like Figure 5 As shown, in this embodiment, the valve ball 3 is a metal valve ball whose outer surface is sprayed with a ceramic coating, that is, the valve ball includes a metal valve core 31 and a ceramic coating 32 coated on the outer surface of the metal valve core. The valve ball inner liner 8 is also sleeved in the center flow channel of the valve ball, and the ceramic coating 32 and the valve ball inner liner 8 are in direct contact with the fluid, thereby protecting the metal valve core 31 from contacting the fluid. At this time, since the inside of the metal valve core 31 is bonded with metal bonds, elastic deformation and plastic deformation will occur inside the metal valve core 31 when subjected to a large torsion force, so the fracture critical torque value of the metal valve core 31 is relatively large. The...

Embodiment 3

[0035] Embodiment 3: A full-lined ceramic three-way ball valve of this embodiment will be described centering on the differences from Embodiment 1.

[0036] like Image 6 As shown, a full-lined ceramic three-way ball valve of this embodiment, the lower valve stem 15 is installed at the lower end of the valve ball 3 in the valve body 1, and a limiting groove 16 is opened on the lower spherical surface of the valve ball 3, and the lower valve stem The upper end of 15 stretches in the limit groove 16, and the bottom of the limit groove 16 is pressed against the end of the lower valve stem 15, the valve ball 3 can be supported on the lower valve stem, and the lower valve stem 15 is limited to the limit. bit slot 16. The lower valve stem provides upward support for the valve ball 3, making the floating valve ball support more stable, preventing non-standard displacement of the valve ball, and ensuring better sealing performance between the valve ball 3 and the valve seat 2. Simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com