Automatic oscillation mixing device for sample pretreatment

A sample pretreatment and mixing device technology, applied in the field of experimental instruments, can solve the problems of inconvenient portability and transfer of equipment, limited oscillation impact force, and large equipment volume, so as to improve the up and down reciprocating oscillation stroke and output force, and reduce mechanical impact. , to ensure the effectiveness of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the drawings and specific embodiments.

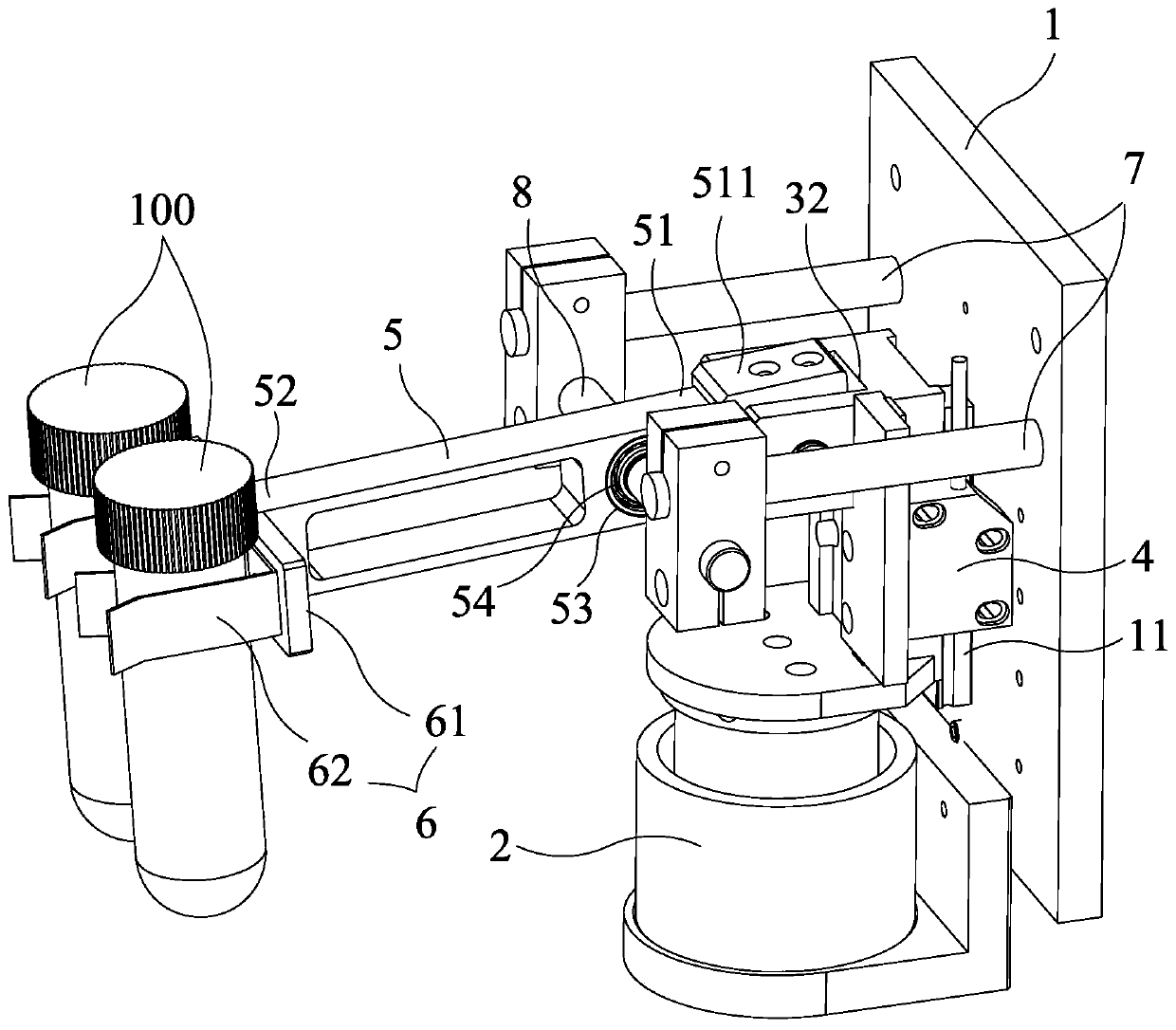

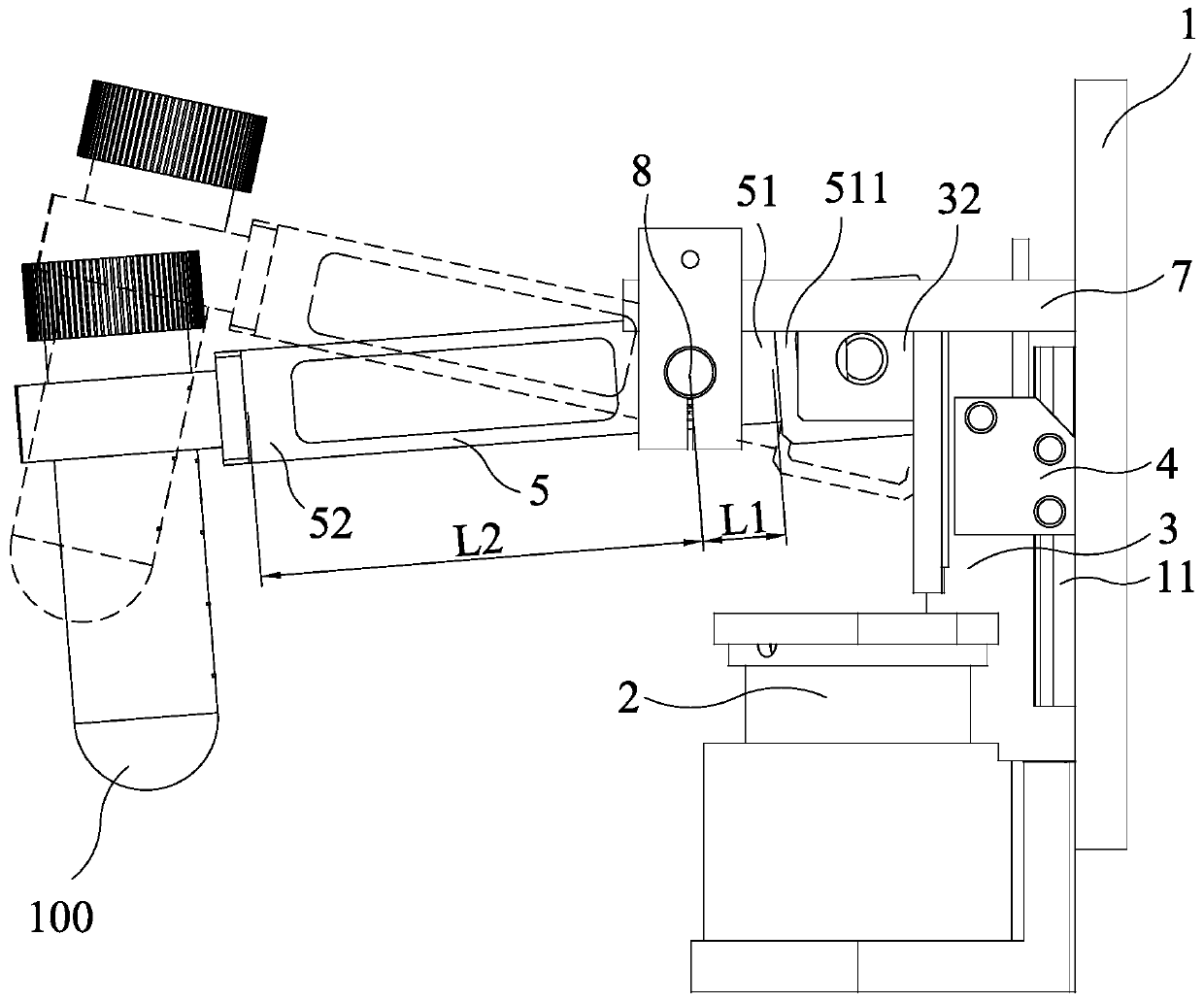

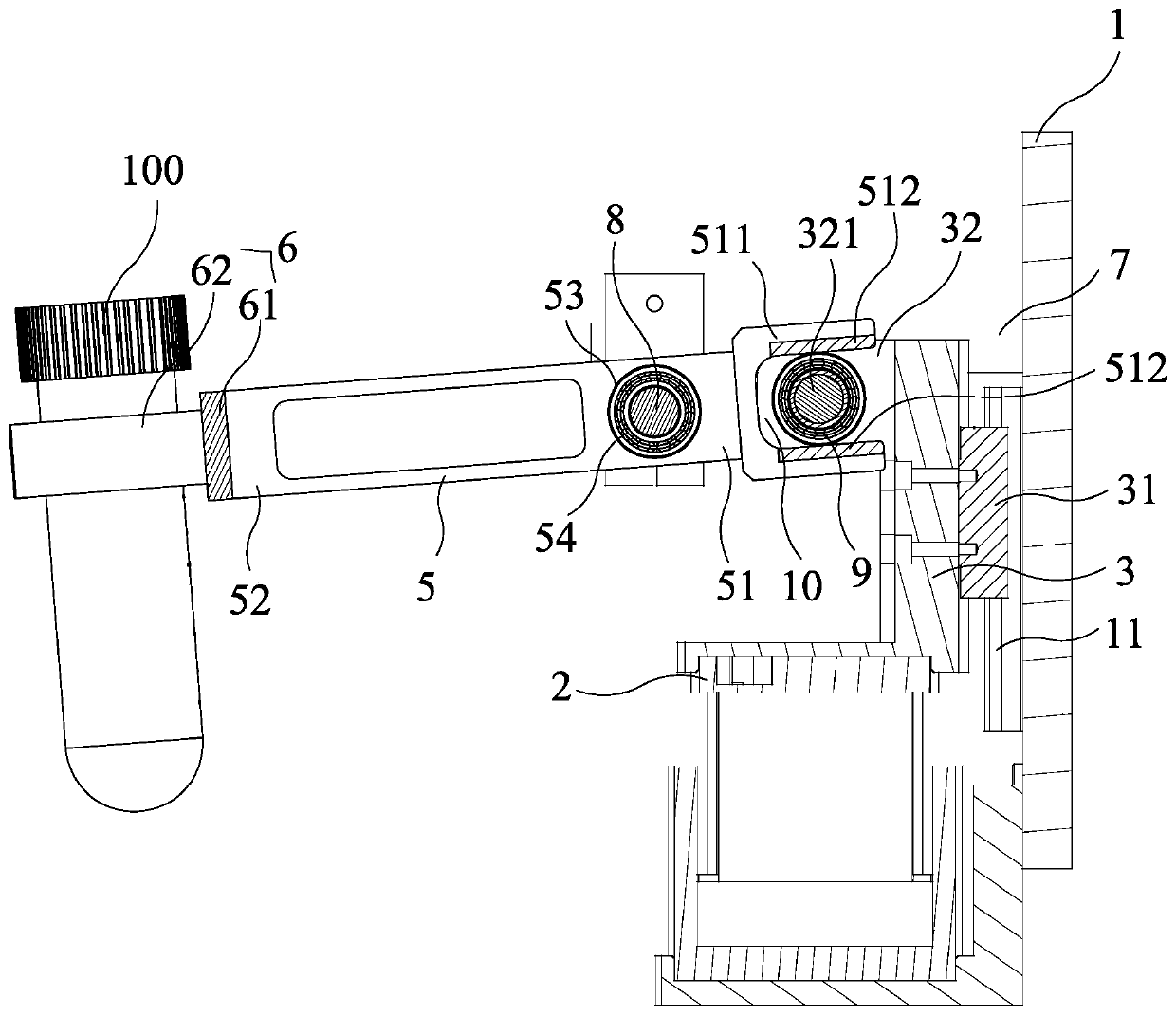

[0025] The present invention provides an automatic oscillating mixing device for sample pretreatment, which includes a frame 1, a voice coil motor 2, a sliding seat 3, a position measuring sensor 4, a rocker 5, a sample tube clamp mechanism 6 and a controller (not shown in the figure) Out), the voice coil motor 2 is fixed on the frame 1, the voice coil motor 2 is vertically connected to the sliding seat 3, the position measuring sensor 4 is arranged on the sliding seat 3, and the rocker 5 is pivotally connected to the machine On the frame 1, the sliding seat 3 is rotatably connected to the head end 51 of the rocker 5, and the head end 51 of the rocker 5 to the pivot joint is the short arm L1. The end 52 of the rocker 5 fixes the sample tube tube clamp mechanism 6, the end 52 of the rocker 5 to the pivot joint is a long arm L2, that is, the head 51 of the rocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com