Heat dissipation assembly

A technology for heat dissipation components and valves, which is applied in digital data processing components, instruments, electrical digital data processing, etc., can solve the problems of affecting the heat dissipation efficiency of heat dissipation components, large flow resistance, and different widths of flow channels, so as to reduce fluid pressure. , Improve heat dissipation efficiency, accelerate the effect of fluid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

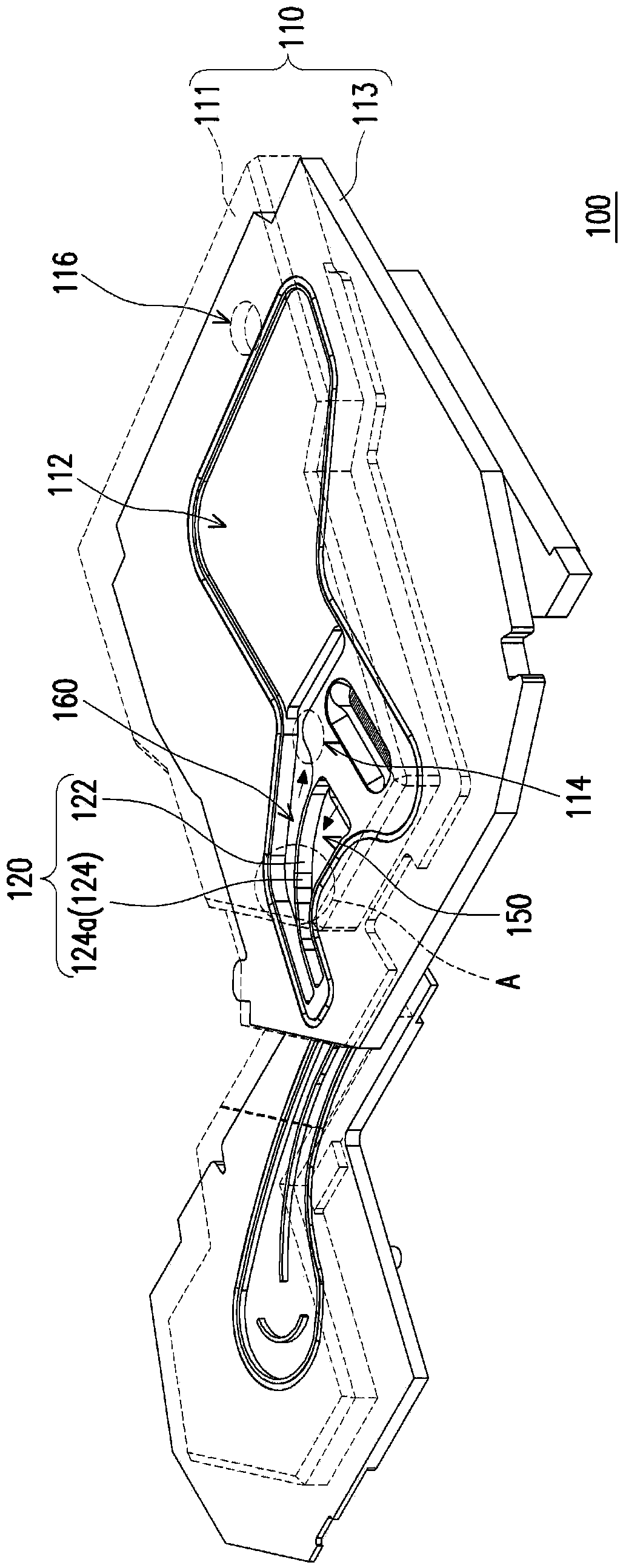

[0051] figure 1 It is a three-dimensional appearance schematic diagram of a heat dissipation assembly according to an embodiment of the present invention. Please refer to figure 1 The heat dissipation assembly 100 is suitable for dissipating heat from a heat source (not shown), and the heat source may be, for example, a central processing unit (CPU), a memory, a south bridge chip, a north bridge chip, or a graphics chip on a computer motherboard. In this embodiment, the heat dissipation assembly 100 has a housing 110 and a partition structure 120 disposed in the housing 110 . The housing 110 has an upper shell 111 and a lower shell 113 , and a chamber 112 is formed between the upper shell 111 and the lower shell 113 . The upper shell 111 includes a first water hole 114 and a second water hole 116 . heat sink assembly 100 in figure 1 In the figure, in order to clearly show the internal structure of the casing 110, the upper casing 111 is represented by a dotted line.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com