Method for embedding flat copper wire by using split stator core

A stator iron core, split type technology, applied in electric vehicles, manufacturing motor generators, electrical components, etc., can solve problems such as short circuit, mutual movement between windings and iron core, etc., to reduce the production process, avoid damage, reduce The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] According to the attached Figure 1-8 The specific embodiment of the present invention is further described:

[0040] This embodiment provides a method for inserting flat copper wires using a split stator core, wherein the split stator core 5 includes a full-circle stator split, and the full-circle stator split consists of a plurality of stator splits Structure 5-1 was formed by splicing.

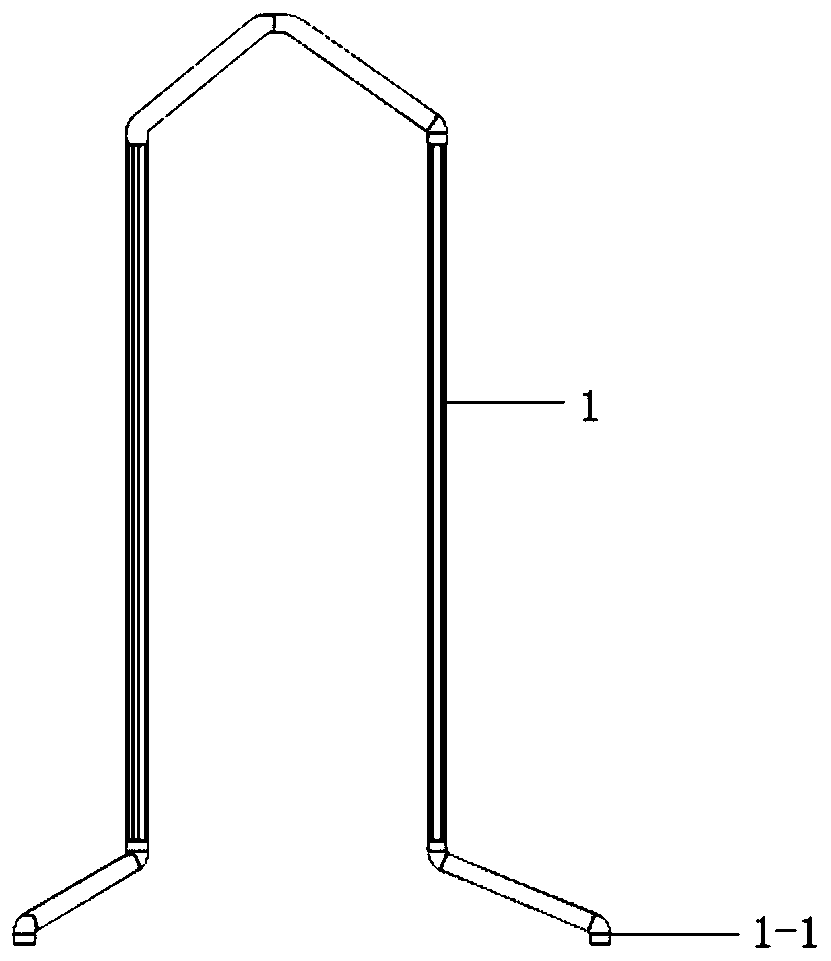

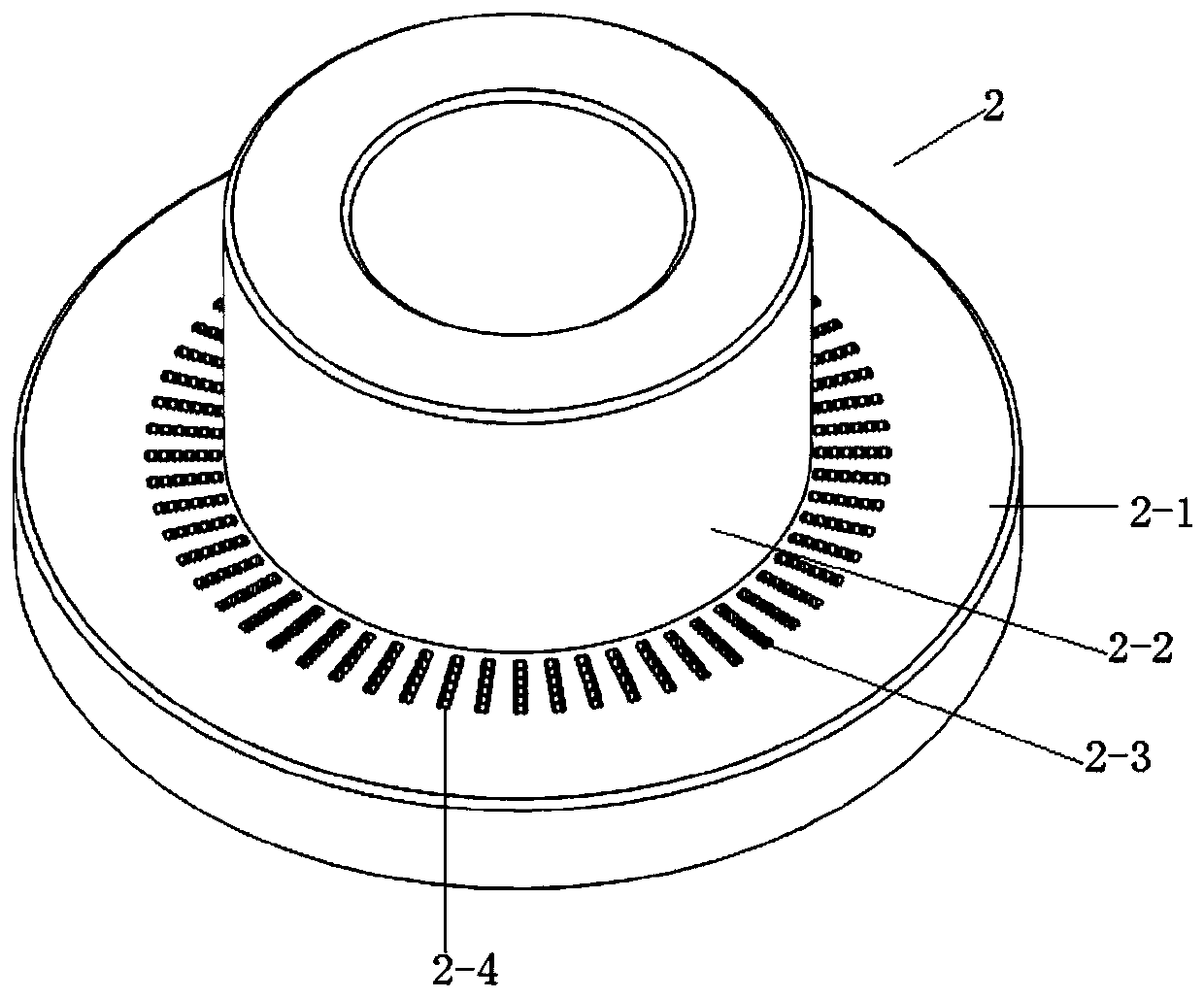

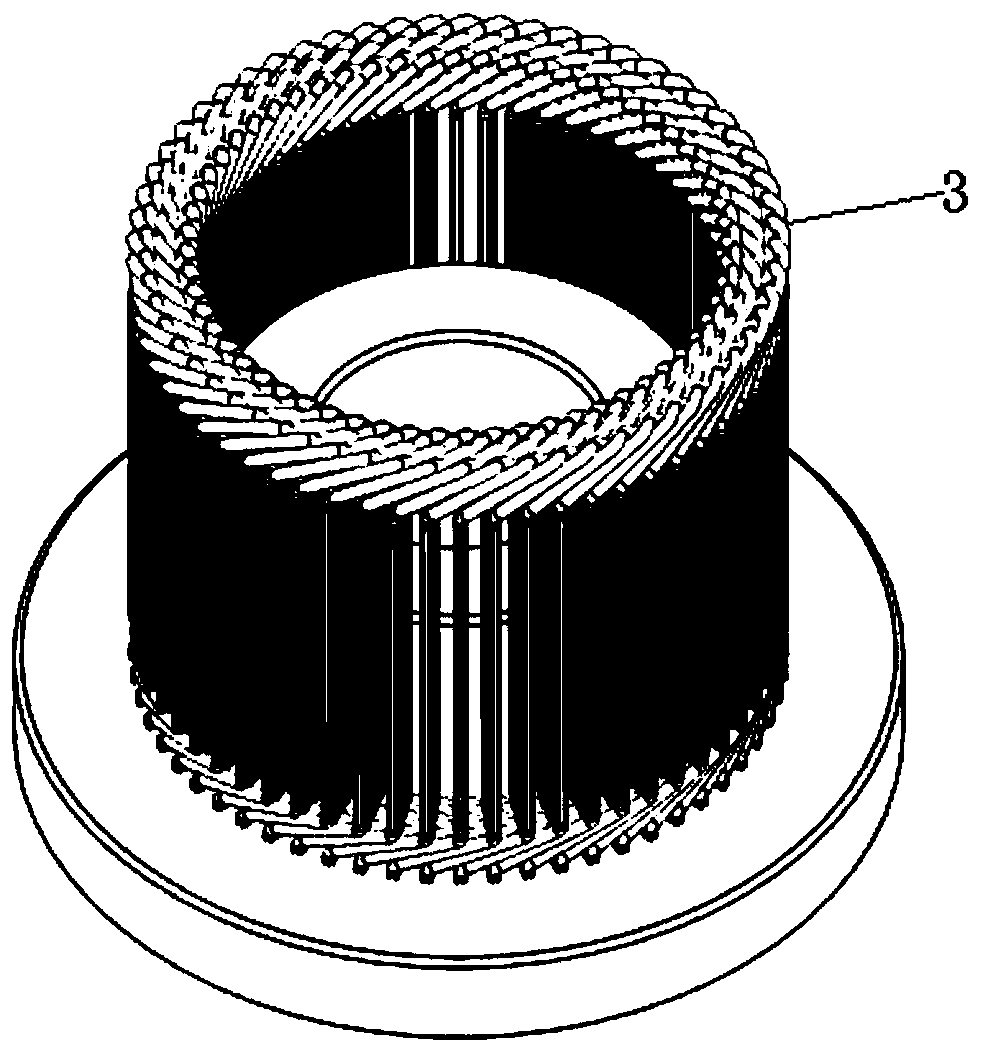

[0041] The method also includes a pre-arrangement mold, the pre-arrangement mold includes a base frock 2 and a split frock 4; as figure 2 As shown, the surface of the base tooling 2 is provided with multiple rows of wire insertion slots 2-3 evenly distributed along its circumferential direction, and each row of wire insertion slots 2-3 is composed of a plurality of wire insertion holes 2-4 arranged in a row ;like Figure 4 and Figure 5 As shown, the split tooling 4 includes full-circle tooling splits, and the full-circle tooling splits are formed by splicing a plurality of tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com