A method for controlling expansion and contraction of printed circuit board core board

A control method and a printed circuit technology, which are applied in the manufacturing of printed circuits, printed circuits, and multi-layer circuits, etc., can solve the problems of different baking degrees and uneven baking of core boards, and achieve uniform heating and uniform temperature. Good performance, reducing the effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The expansion and shrinkage control method of the printed circuit board core board of the present invention will be further described in detail in combination with specific embodiments and accompanying drawings.

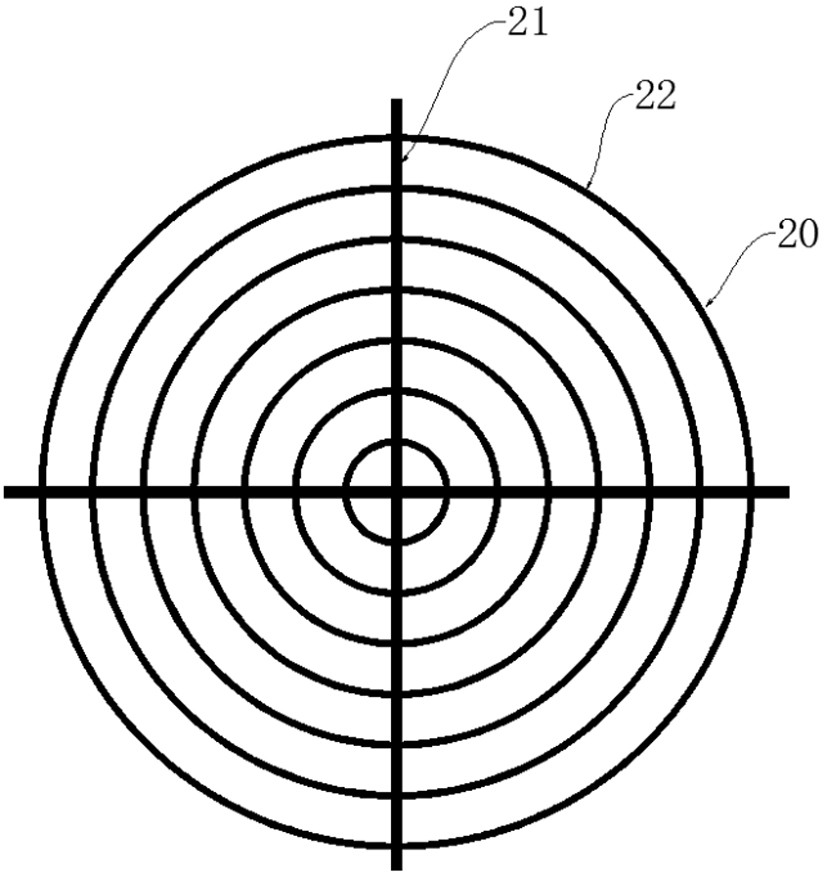

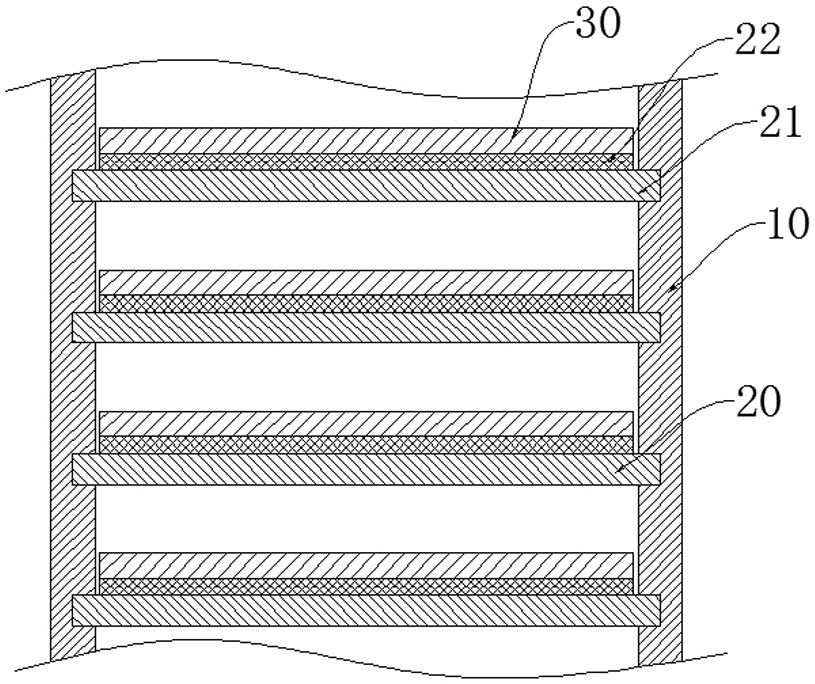

[0020] refer to figure 1 , figure 2 , a non-limiting embodiment of the present invention, a method for controlling the expansion and contraction of the core board of a printed circuit board, the control method is to control the expansion and contraction of the core board 30 by using layered baking plates in the baking process method. The expansion and contraction control method of the core board of the printed circuit board of the present invention is carried out by adopting the mode of layered baking boards, and the layered baking boards can be used to place the core boards 30 in layers, and each core board 30 is heated evenly up and down, so that the core boards The temperature uniformity of the 30 baking plate is good, the stability of the baking plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com