Production method of high-absorption nano-calcium and product and application thereof

A production method and nano-calcium technology, applied in the application, food freezing, food ingredients and other directions, can solve the problems of low solubility and large side effects, and achieve the effects of high solubility, simple production method and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

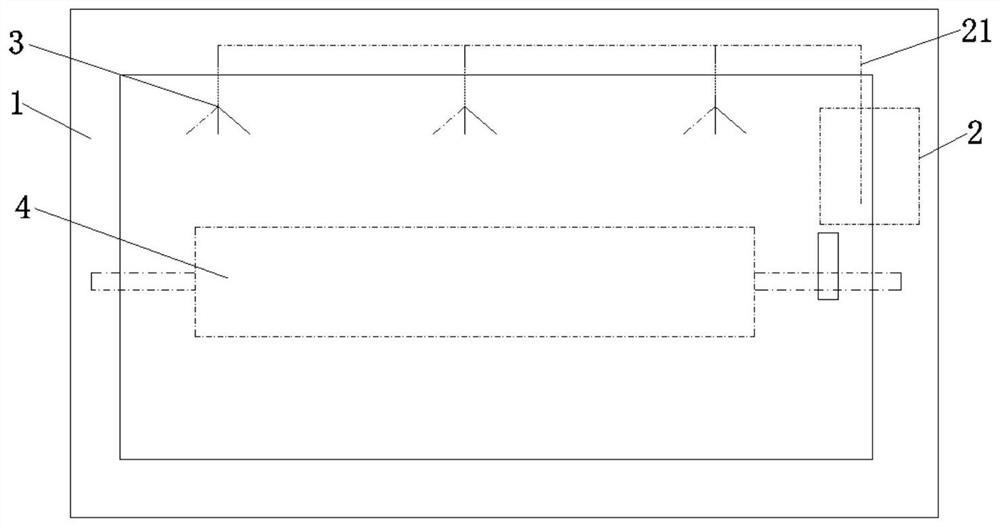

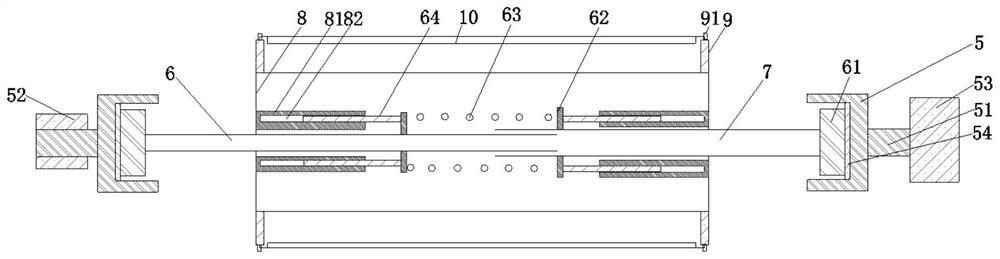

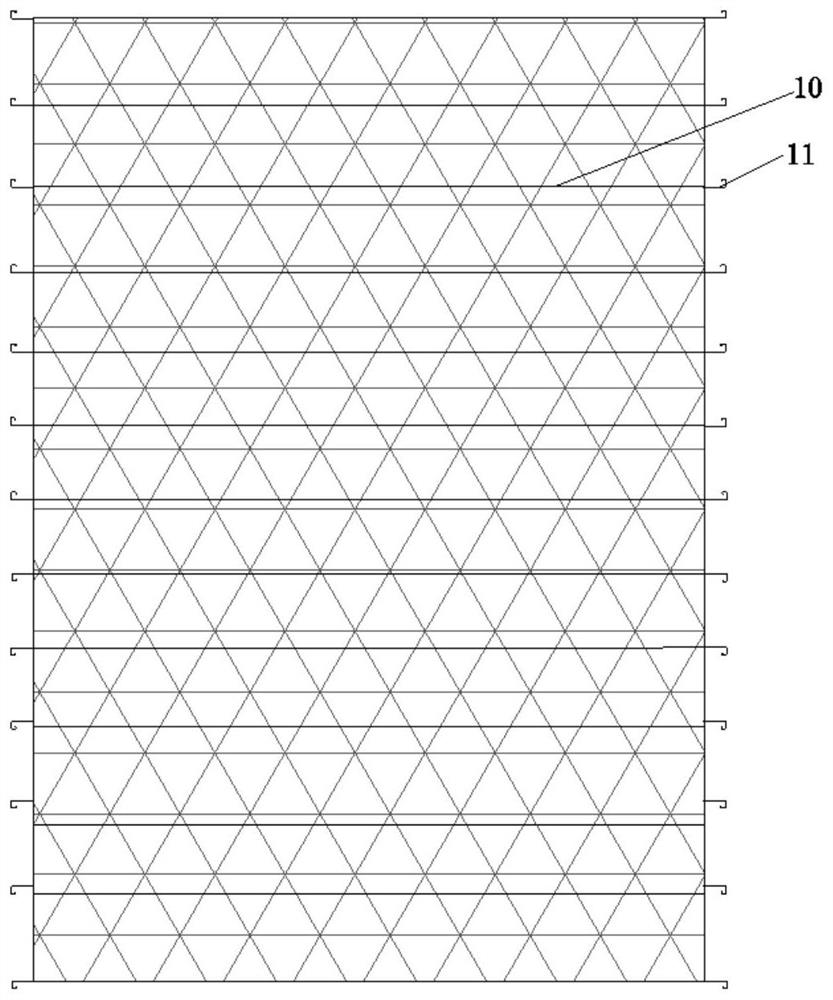

Method used

Image

Examples

Embodiment 1

[0042] The production method of highly absorbing nano-calcium comprises the following steps:

[0043] Step 1. Wash the eggshells with water, lye, and water in turn, and then bake them at 55°C, 90°C, 170°C, 90°C, and 45°C for 3 minutes, 8 minutes, 8 minutes, 3 minutes, and 3 minutes respectively, and then bake them at 55°C, 90°C, 170°C, 90°C, and 45°C. During the drying process at this temperature, spray the organic acid on the surface of the eggshell every 20s, then crush the baked eggshell to obtain eggshell powder, add an organic acid of 1 times the quality of the eggshell powder to the eggshell powder, and Soak at 20°C, 38°C, 60°C, 80°C, and 38°C for 2h, 4h, 18h, 15h, and 4h respectively, then filter and collect the calcium acid solution;

[0044]Wherein, the lye is an aqueous solution of sodium bicarbonate with a mass fraction of 3%, the particle diameter of the eggshell powder is less than 100 mesh, and the organic acid used for spraying is of the same type as the organic...

Embodiment 2

[0050] The production method of highly absorbing nano-calcium comprises the following steps:

[0051] Step 1. Wash the eggshells with water, lye, and water in turn, and then bake them at 60°C, 100°C, 180°C, 100°C, and 50°C for 5 minutes, 10 minutes, 10 minutes, 5 minutes, and 5 minutes respectively, and then bake them for 5 minutes. During the drying process at this temperature, spray the organic acid on the surface of the eggshell every 30s, then pulverize the baked eggshell to obtain eggshell powder, add an organic acid twice the quality of the eggshell powder to the eggshell powder, and Soak at 25°C, 42°C, 65°C, 90°C, and 42°C for 3h, 5h, 20h, 18h, and 5h respectively, then filter and collect the calcium acid solution;

[0052] Wherein, the lye is a sodium bicarbonate aqueous solution with a mass fraction of 5%, and the particle diameter of the eggshell powder is less than 100 meshes, and the organic acid used for spraying is of the same type as the organic acid used for so...

Embodiment 3

[0058] The production method of highly absorbing nano-calcium comprises the following steps:

[0059] Step 1. Wash the eggshells with water, lye, and water in turn, and then bake them at 55°C, 95°C, 175°C, 95°C, and 50°C for 4 minutes, 9 minutes, 9 minutes, 4 minutes, and 4 minutes respectively, and then bake them at 55°C, 95°C, 175°C, 95°C, and 50°C respectively. During the drying process at this temperature, spray the organic acid to the eggshell surface every 25s, then crush the baked eggshell to obtain eggshell powder, add 1.5 times the organic acid of the eggshell powder quality to the eggshell powder, and Soak at 25°C, 40°C, 65°C, 85°C, and 40°C for 2.5h, 4.5h, 19h, 16.5h, and 4.5h respectively, then filter and collect the calcium acid solution;

[0060] Wherein, lye is the sodium bicarbonate aqueous solution that mass fraction is 4%, and the particle diameter of eggshell powder is less than 100 meshes, and the organic acid of spraying and soaking are of the same kind, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com