Wine brewing equipment

A technology for equipment and buckets, applied in the field of winemaking, can solve the problems of easy adhesion to containers and containers, splashing and dripping of liquids, and increasing labor burden, so as to shorten the heat dissipation time, enhance the quality, and improve the stirring effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

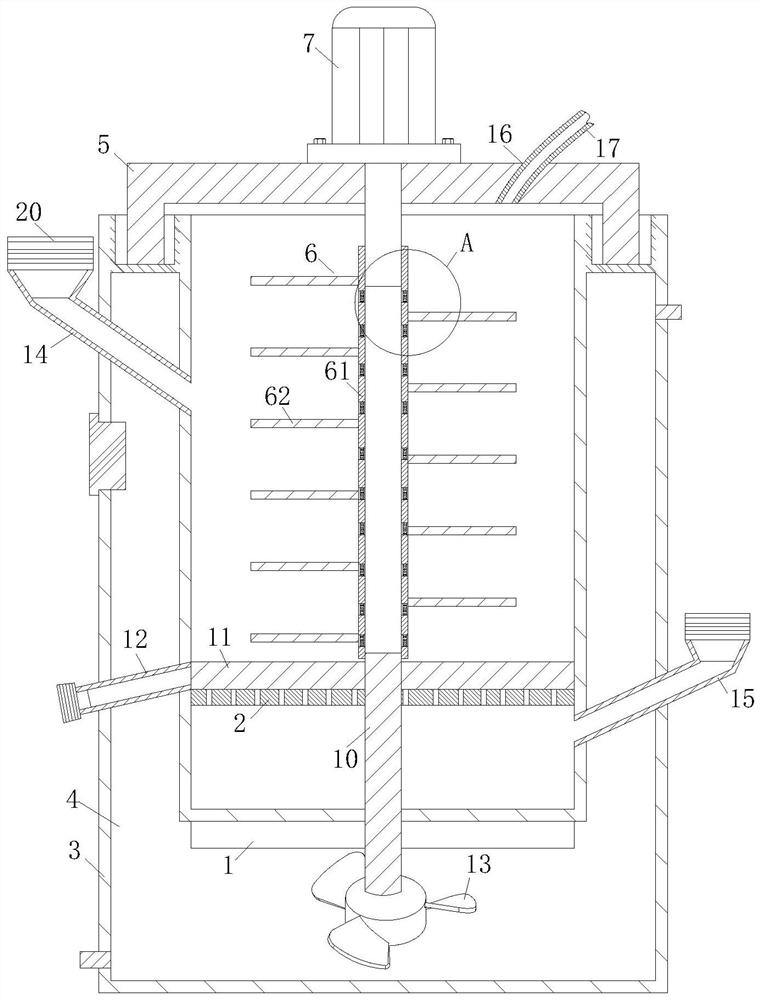

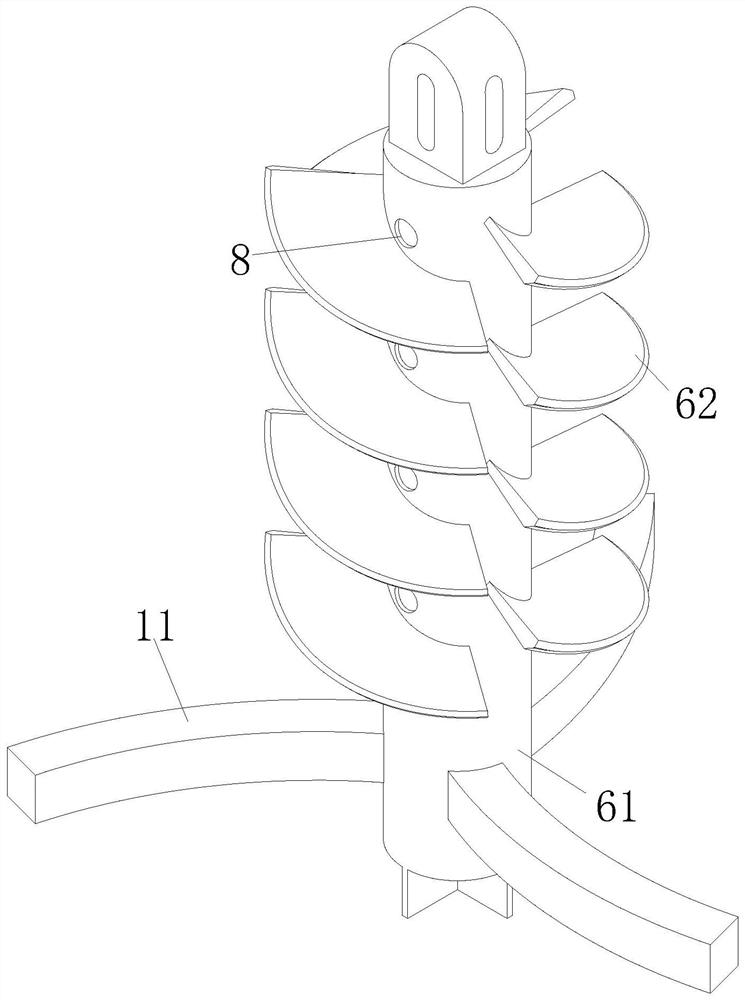

[0048] As an embodiment of the present invention, the mixing device 6 includes:

[0049] The ventilation pipe 61, the inner surface of the ventilation pipe 61 is fixedly connected with the rotating shaft of the motor 7;

[0050] a plurality of crushing knives 62, the multiple crushing knives 62 are all fixedly connected with the outer surface of the ventilation pipe 61, the multiple crushing knives 62 are arranged staggered, and the width of the blade back of the crushing knives 62 ranges between 2-4 mm;

[0051] By adopting the above-mentioned technical solution, when people add the grains to the steaming tray 2 in the discharging bucket 3, according to the control switch of the motor 7, the motor 7 is started to rotate forwardly, and the rotating shaft of the motor 7 rotates forwardly to drive the ventilation pipe 61 fixedly connected to it. Forward rotation, the forward rotation of the ventilation pipe 61 drives the multiple crushing knives 62 fixedly connected on it to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com