An automated production system for building flaps

A production system, a technology for building boards, applied in ceramic molding machines, manufacturing tools, ceramic molding workshops, etc., can solve problems such as inability to contact hot air, and achieve the effects of preventing material hardening, stable performance, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

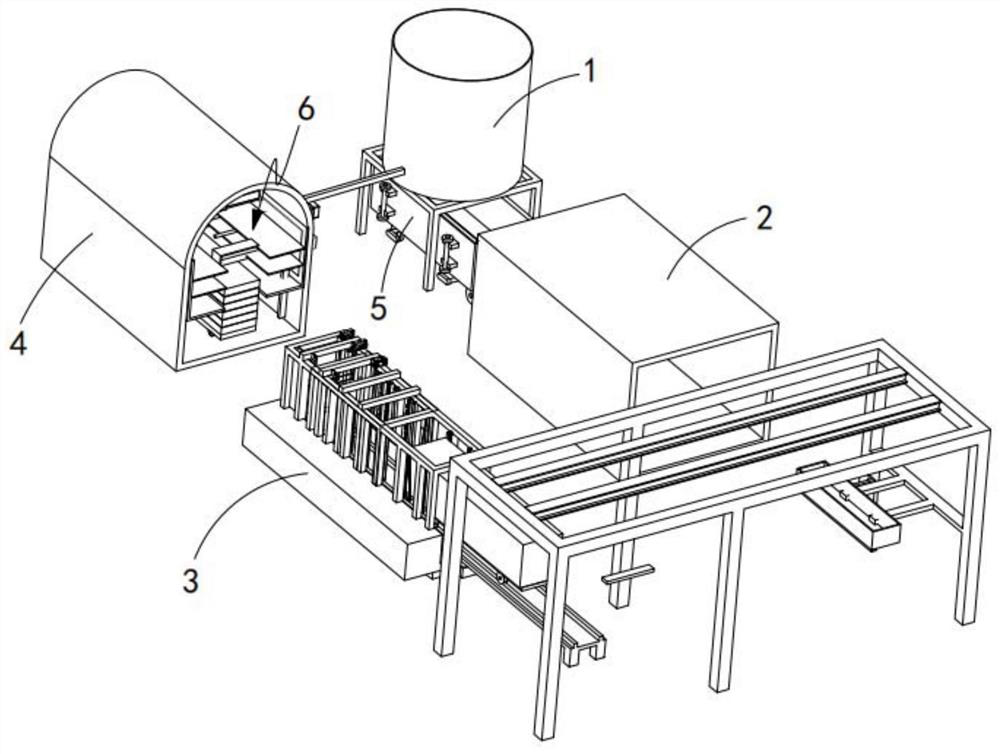

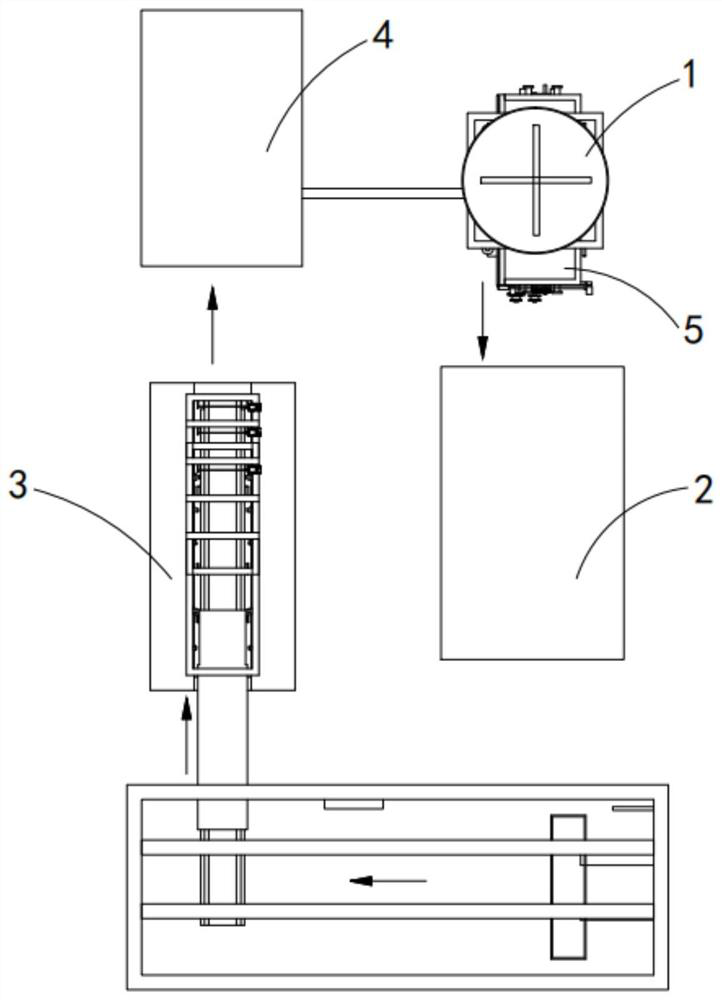

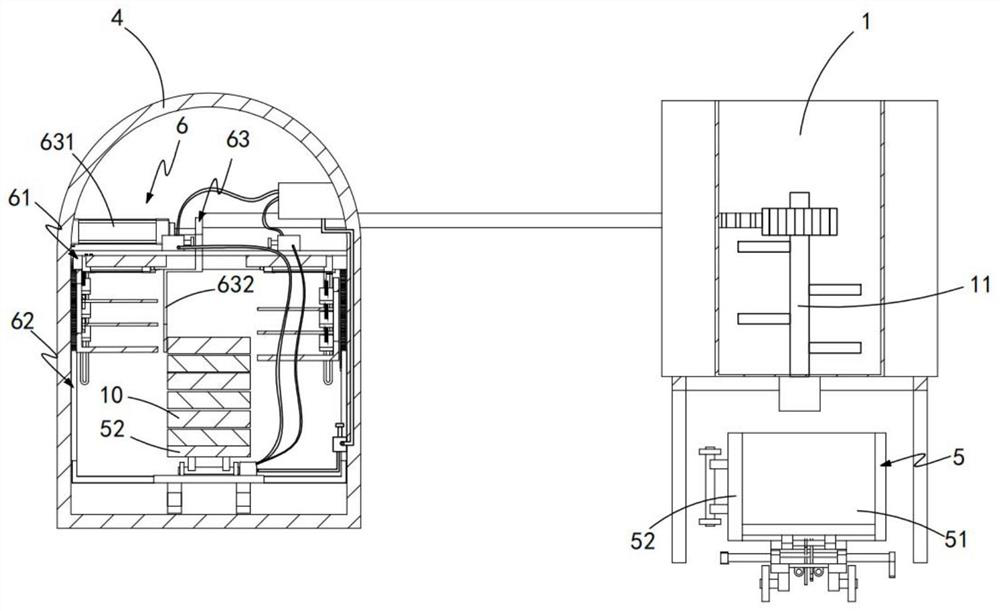

[0043] like Figures 1 to 4 As shown, an automatic production system for building flaps includes a pouring device 1, a static curing device 2, a cutting device 3, a steam curing device 4 and a mold assembly 5. The mold assembly 5 passes through the pouring device 1 and the static curing device 2 in turn to complete the blank. The body is cast and formed, and the green body is cut by the cutting device 3 and then sent to the steam curing device 4 for steam curing and drying to form a building board 10, which is characterized in that it also includes a dislocation layer arranged in the steam curing device 4. Mechanism 6, the dislocation layering mechanism 6 displaces and separates the building boards 10 from each other and inserts them together.

[0044] Further, the dislocation layering mechanism 6 includes a layering frame assembly 61, a lifting assembly 62 for driving the layering frame assembly 61 to rise and fall, and a lifting assembly 62 disposed on the upper part of the ...

Embodiment 2

[0051] like Figures 3 to 7 As shown in the figure, the same or corresponding parts as those in the first embodiment are marked with the reference numerals corresponding to those in the first embodiment. For the sake of brevity, only the differences between the second embodiment and the first embodiment are as follows: the difference between the second embodiment and the first embodiment at:

[0052] like image 3 As shown, in this embodiment, the mold assembly 5 includes a frame body 51 and a side plate 52. After the mold assembly 5 passes through the resting device 2, the frame body 51 is removed, and the side plate 52 carries body movement;

[0053] like Figures 4 to 7 As shown, the lifting assembly 62 includes a jacking oil cylinder 621 , an oil storage tank 622 , an oil pump unit 623 , a linkage unit 624 and an oil return control member 625 , and the jacking oil cylinder 621 is arranged on the bottom top of the steam curing device 4 To lift the side plate 52 , the oi...

Embodiment 3

[0058] like Figures 8 to 16 As shown in the figure, the same or corresponding parts as those of the first embodiment are marked with the corresponding reference numerals of the first embodiment. For the sake of brevity, only the differences between the second embodiment and the first embodiment are as follows: the difference between the third embodiment and the first embodiment at:

[0059] In this embodiment, the placing unit 612 includes a plurality of support plates 6121, limit locks 6122 and return springs 6123 arranged in layers. Through the insertion and engagement of the plug-in portion 6124, the limit lock 6122 passes through the plug-in portion 6124 to limit the position of the support plate 6121 at the bottom, and the return spring 6123 is arranged between the adjacent support plates 6121. .

[0060] It should be noted that the multi-layer support plates 6121 are kept at a certain distance and locked by the limit locks 6122, the building boards 10 are placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com