Electric power conversion device

A technology for power conversion devices and power terminals, which is applied to circuits, electrical components, and electrical solid devices, to achieve cooling performance and productivity improvements, reduce manufacturing man-hours, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0059] refer to Figure 1 to Figure 12 Embodiments of the power conversion device will be described.

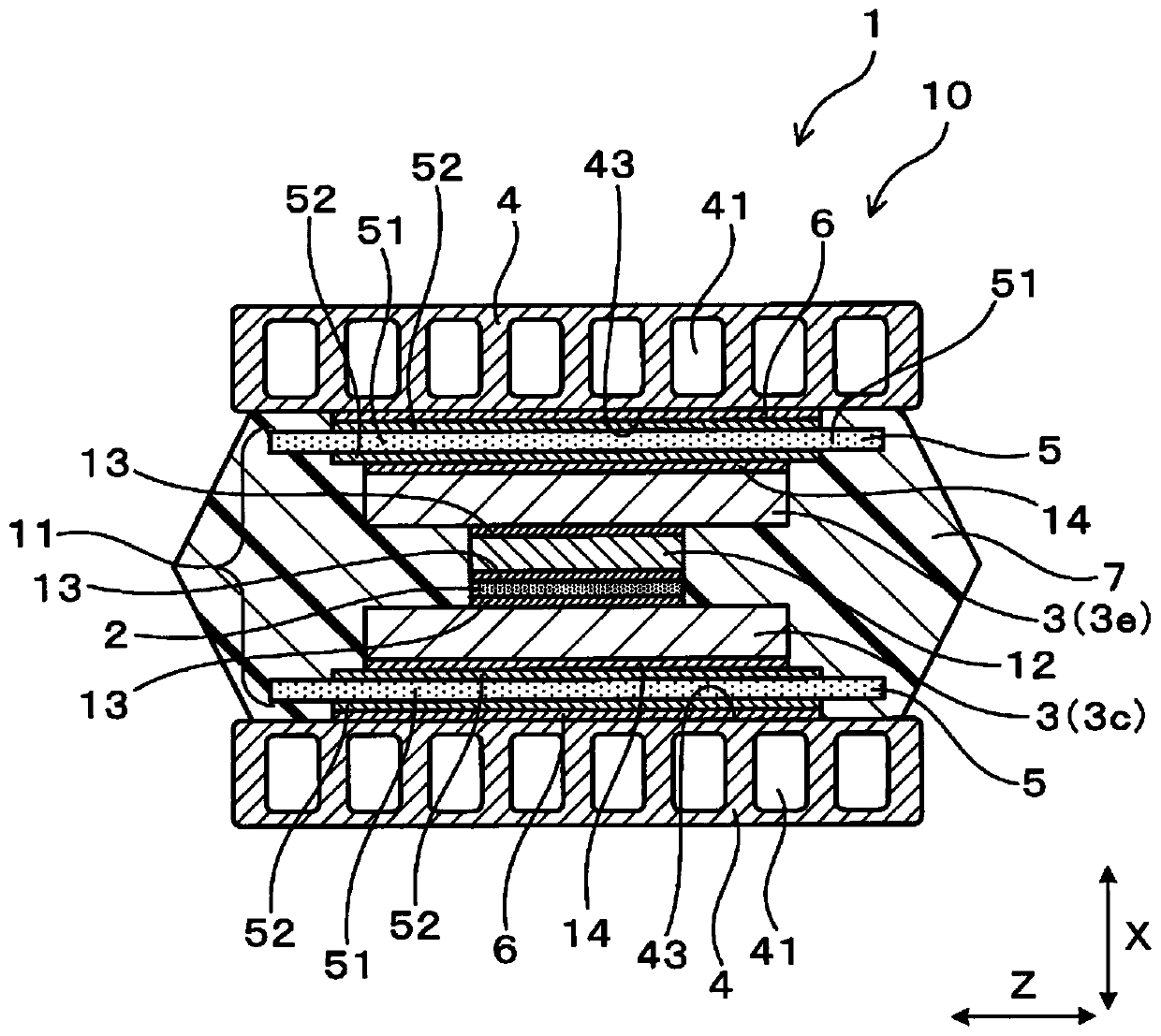

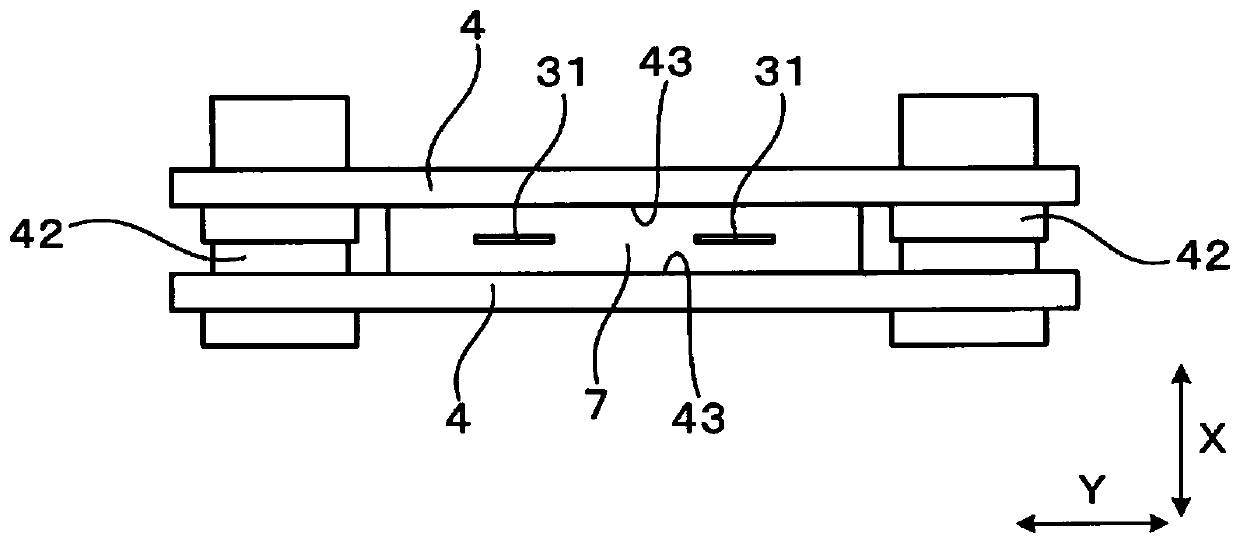

[0060] Such as figure 1 As shown, the power conversion device 1 of the present embodiment has a semiconductor element 2 , a plurality of lead frames 3 , a cooling pipe 4 , an insulating portion 5 , a metal bonding material 6 , and a resin sealing portion 7 .

[0061] The lead frame 3 is electrically connected to the semiconductor element 2 . The cooling pipe 4 is one form of a channel forming body in which a refrigerant channel 41 through which the refrigerant flows is formed. The insulating part 5 is arranged between the lead frame 3 and the cooling pipe 4 to insulate them. Metal joint material 6 joins insulating portion 5 and cooling pipe 4 . The resin sealing portion 7 seals the semiconductor element 2 and the lead frame 3 .

[0062] The resin sealing portion 7 integrates the semiconductor element 2 and the lead frame 3 with the cooling pipe 4 to form a semiconductor ...

Embodiment approach 2

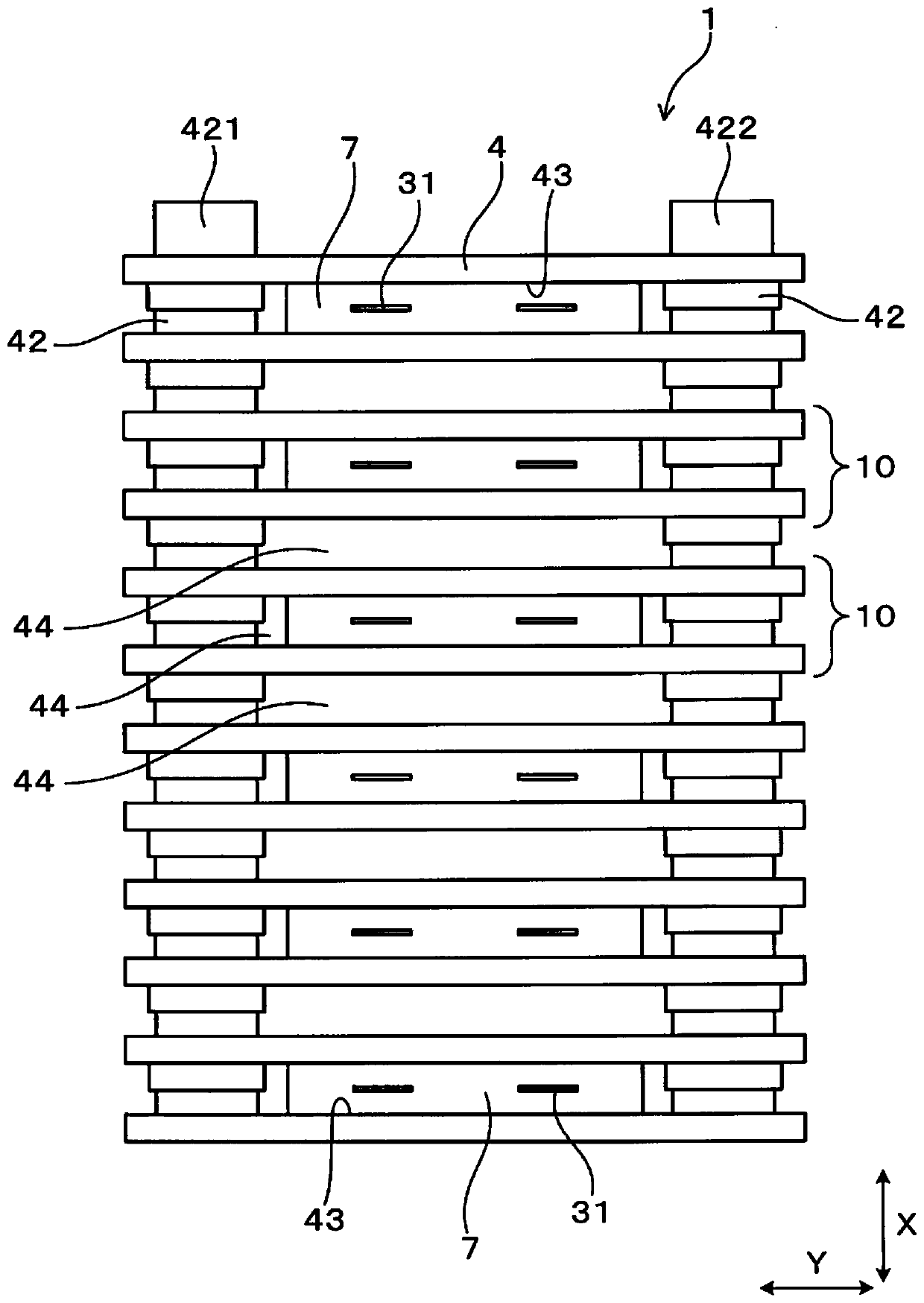

[0098] In the power conversion device 1 of the present embodiment, if Figure 13 As shown, the semiconductor cooling unit 10 has a plurality of semiconductor components 2 . That is, one semiconductor cooling module 10 has a plurality of semiconductor elements 2 arranged side by side in a direction perpendicular to the stacking direction X between a pair of cooling pipes 4 . also, Figure 13 is a cross-sectional view of the semiconductor cooling module 10 on a plane perpendicular to the longitudinal direction Z.

[0099] In this embodiment, a plurality of semiconductor elements 2 are arranged side by side in the lateral direction Y.

[0100] In addition, at least two of the plurality of semiconductor elements 2 in the semiconductor cooling unit 10 are an upper arm semiconductor element 2u and a lower arm semiconductor element 2d connected in series to each other. In addition, in this embodiment, the number of semiconductor elements 2 built in the semiconductor cooling unit 1...

Embodiment approach 3

[0117] Such as Figure 18 ~ Figure 20 As shown, the power conversion device 1 of the present embodiment has a configuration in which the insulating portion 5 is arranged over the two laminated component groups 11 .

[0118] That is, if Figure 18 As shown, two laminated component groups 11 share two insulating portions 5 . One insulating portion 5 is bonded to an opposing surface 43 of one cooling pipe 4 via a metal bonding material 6 . In addition, one insulating portion 5 is bonded to the opposing surface 43 of the other cooling pipe 4 via the metal bonding material 6 . Further, two semiconductor elements 2 are arranged side by side together with the lead frame 3 and the terminal chip 12 between the pair of insulating portions 5 arranged to face each other in the stacking direction X. As shown in FIG.

[0119] In addition, in this embodiment, if Figure 18 , Figure 19 As shown, on one main surface of the insulating portion 5, two metal layers 52 are formed at two posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com